(It is early

September when we meet Gerhard Ulmer in his office on the second story of the

STAMA premises in Schlierbach. Given the structural change in the automotive

industry already apparent from late 2018 and the COVID-19 pandemic, which has

dominated everything since March 2020, an entire industry is facing what is

certainly one of its most difficult challenges of recent times. This is also

true of STAMA Maschinenfabrik, now in its 82nd year of operation.)

Coronavirus is

everywhere, and many holiday destinations have been and remain high-risk areas.

Where did you go on holiday with your family this year?

For a number of years now, we've spent one week

at a coastal resort and one in the mountains. So the coronavirus crisis didn't

change things very much for us.

When you're on

holiday, do you prefer to sleep in or are you already jogging at 7 a.m.?

I can't really sleep in on holiday; my body

clock doesn't change that quickly. I just spend that time doing different

things like handiwork around the house and lots of reading. Unfortunately, I don't do much sport on holiday

– I still fall short in that area.

How well have you

been able to keep a work-life balance over your past 14 years as the Head of

Sales at STAMA?

In this job, it's almost impossible to keep

business totally separate from your private life. I've set some rules for

myself. For example, I only read e-mails in the evening and ring people back at

specific times. But I'm never really totally removed from the business side of

things.

A practical

question now – when the lease for your company car runs out, would you opt for

an electric car?

In my job, I have to drive around a lot so with

a pure electric car you'd have to be extremely organized. There are a limited

number of charging points and they also have time restrictions, so you'd need

to plan ahead. But I could imagine using a full hybrid as an interim solution.

I currently drive a mild hybrid with a diesel engine.

Following the

emissions scandal for diesel engines, it's now suspected that values for

gasoline engines have also been manipulated, with the Audi Q5 TFSI 2.0 cited as

an example. It is alleged that this car's steering lock changed the emissions

values. How much of a future do combustion engines still have?

When you take account of all of the climate

issues and industry policy considerations, that's not the key question. We're

in a situation where different types of drives are competing against each

other. We're seeing a mobility sector in the midst of a revolution. With the

development towards using hydrogen as a fuel, as well as synthetic e-fuels,

combustion engines will certainly have a role to play in the longer term. How

personal mobility looks in ten years' time will depend on which of the

currently available mobility concepts wins out. It is certainly possible that

various concepts will be used in parallel. It's not just cost-effectiveness

which matters nowadays but also environmental protection, conserving resources

and sustainability. For mechanical engineers like us, this market

situation means that we must set up our production facilities in a flexible

manner in order to successfully adapt to the challenges ahead.

According to the

German Association of the Automotive Industry (VDA), close to 80 million

passenger cars were manufactured globally in 2019. That is a good five million

fewer than in 2018. In Germany, the production figures fell by 16% between 2017

and 2019. To what extent is STAMA affected by this development – after all,

automotive business makes up a good two-thirds of the company's turnover.

For drivetrain and powertrain mechanisms, STAMA

has two key areas of expertise – injection technology and turbochargers. We've

also got applications on the market for the chassis, steering and brakes areas. The ongoing mobility revolution means that many

parts used in production will change. We need new solutions! And processes we

haven't even heard of yet! The market will continue to shift in the direction

of Asia. The best example of this is still China – where production figures are

rising and opportunities for growth are deemed to be better. Of course, this

also means that there will be fiercer competition to find the best solution.

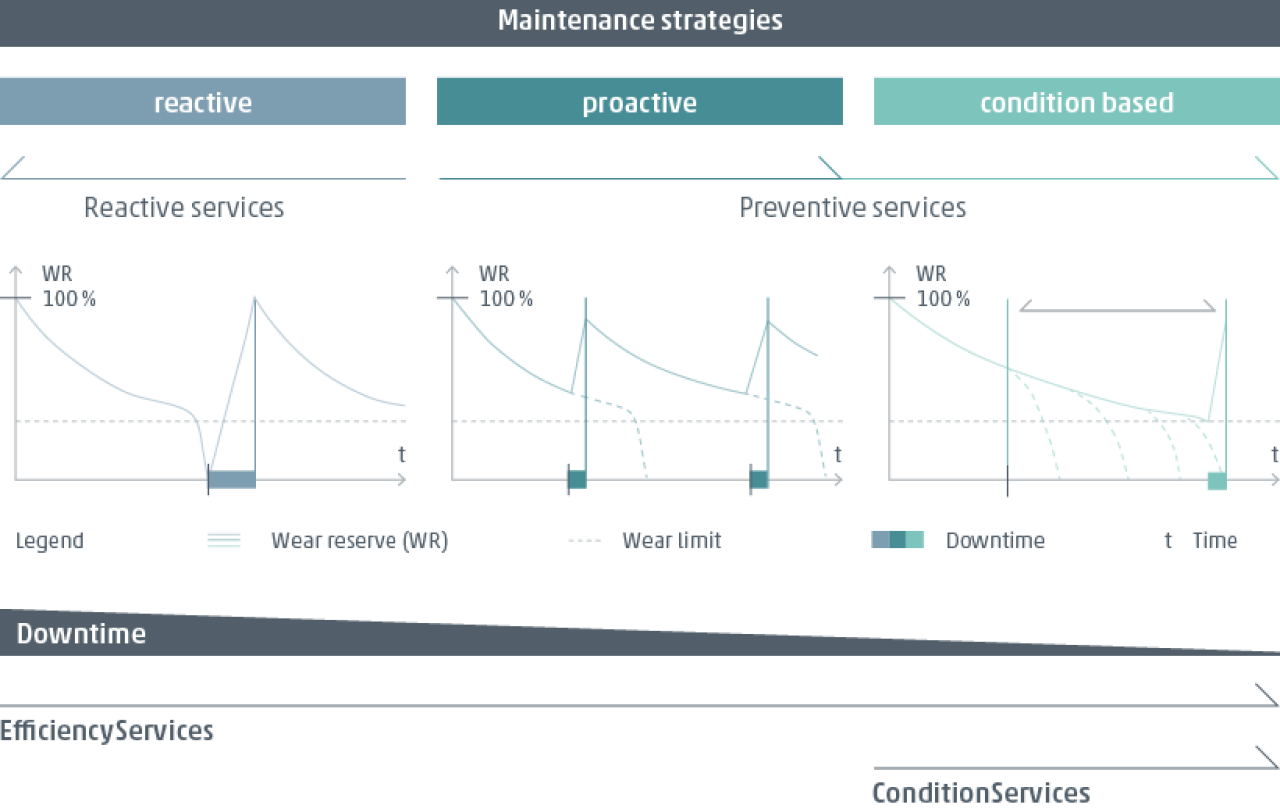

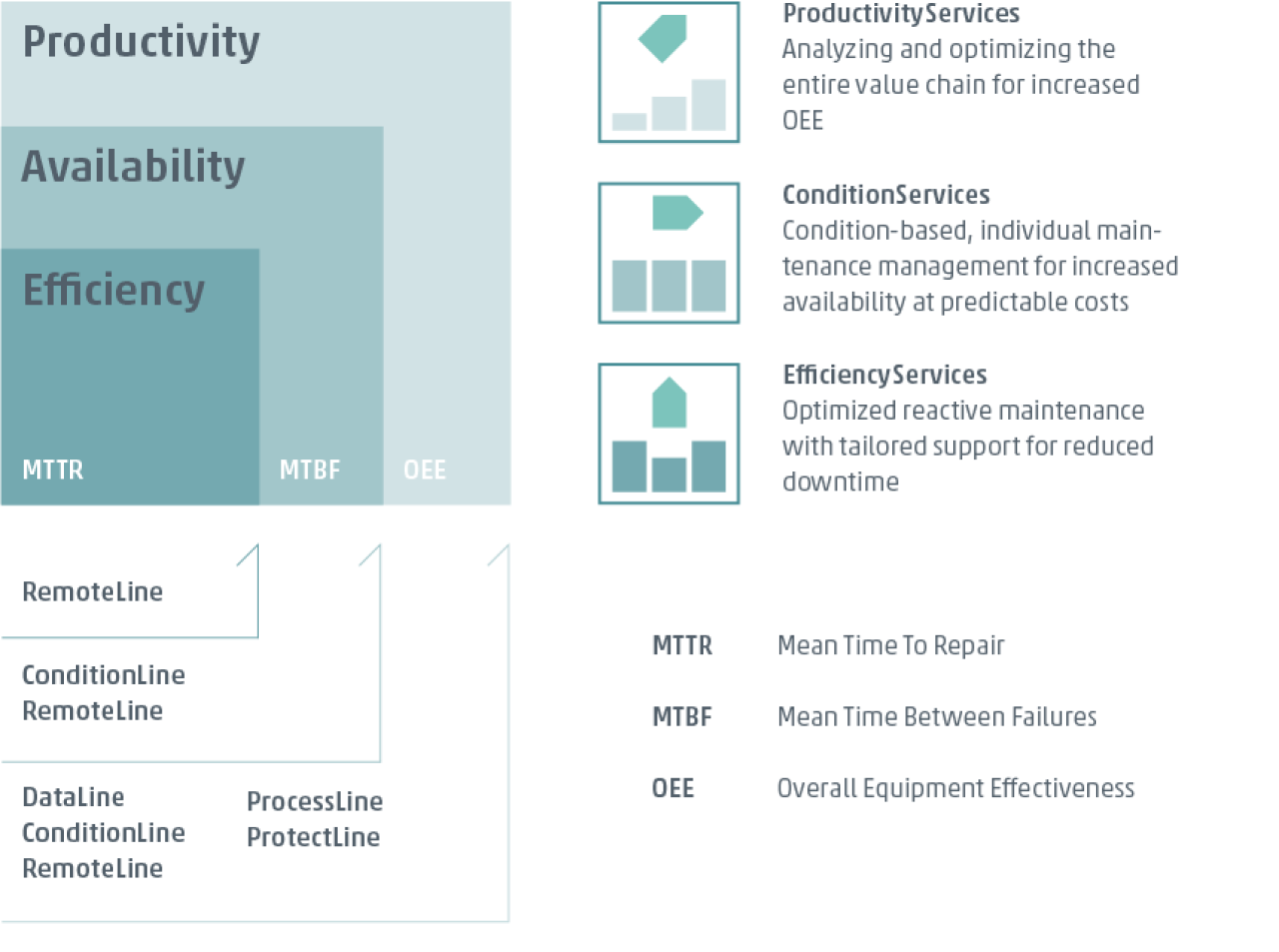

For continued success in the future, we must construct versatile machines – with the key

objectives of reducing set-up times and improving availability (OEE) – as well

as maintaining our first-rate international sales. And we'll succeed together

in achieving this.

Tool manufacturers

constitute a large market segment for STAMA, at a good 15% of the market. A

considerable number of manufacturers use STAMA's MT technology. How do you

assess the future development in this area?

I'm quite positive. In terms of expertise and

experience, what we've built up in this segment over the past 20 years can be

applied to all industries extremely well. This has been the case with the MT

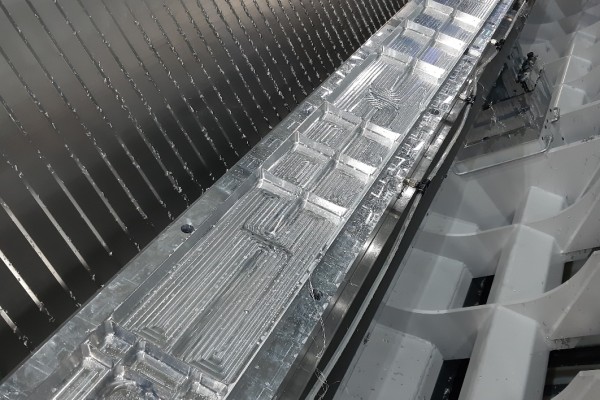

733 Series. Complete machining will certainly be a key technology in the

upcoming changes at production facilities all around the world. This is because

it's unrivaled in combining two elements – high flexibility and high

productivity.

Since the 1980s,

STAMA has been renowned for its highly productive TWIN machines. Do they play a

major role in the current product range and will they do so in the future, for

example to open up new markets?

Yes, they do. As you've already mentioned,

STAMA grew thanks to its two-spindle machining systems for high-capacity series

production. We believe that there's further potential across industries. In 2003, we combined the 8 Series TWIN with MT.

Our customers appreciate the combined benefits of multiple spindles, five-axis

technology and milling-turning functionality – and this will still be the case

in the future. With our experience and knowledge of perfectly bringing high

productivity with high flexibility to meet individual requirements, we're at

the forefront in this field.

In your marketing

material, you describe STAMA as "the turnkey factory". Please briefly

explain what this means.

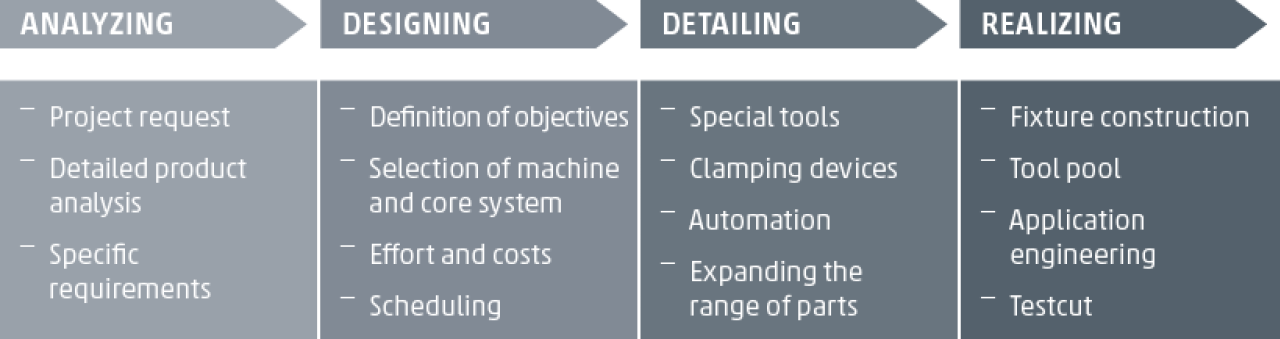

Turnkey solutions are at the core of the STAMA

brand. We now supply customers with the complete technology package for 90% of

our machines. We'll find the best solution for them and select the right

machine from our product range. Our aim is to machine workpieces to the

required quantity and quality, while also achieving the best unit costs. This

means that we're a turnkey factory rather than a pure machine manufacturer and

STAMA puts this spirit into practice.

STAMA is affected

by one aspect of the CHIRON Group's restructuring measures – the relocation of

manufacturing and assembly from Schlierbach to the sites at Neuhausen ob Eck

and Tuttlingen – what can you tell us about this decision?

When it was first announced, this decision must

have been difficult for all those affected to understand or even to comprehend.

But, as was already indicated in the press releases, STAMA, the CHIRON Group

and the entire industry are facing considerable reductions in incoming orders

and this has certain consequences that are now also being felt by STAMA. It's

becoming increasingly important to manufacture the machines where they're used.

In our target market of China, the new CHIRON Group plant was therefore

established in the city of Taicang and designed using state-of-the-art methods

and technology. Similarly, the new plant at Neuhausen ob Eck was set up for our

entire European market. Gaining a competitive advantage by cost-optimizing our

machines and assembling them with a high degree of digitalization is part of

the CHIRON Group's strategic approach. Having spent 33 years at STAMA and gone through

the crises of 1993 and 2008/2009, I've learned that things certainly won't be

easy and it will probably take a few years before we've worked our way back to

a strong economic position. But in order to come out of this crisis and reach

that point again, it's vital that, in addition to offering new innovative

products, we remain structurally and organizationally flexible. STAMA will also

succeed in this area.

The service team

makes a key contribution to the total turnover and, like the sales team, will

still be based in Schlierbach. Does this mean that the two elements of

"point of sale" will stay the same

location together?

Yes! At the end of the day, customer

satisfaction is key. It's therefore important that the sales and service teams

are and remain closely interlinked – both with respect to their

mindset

and location. Our turnkey factory's

areas of expertise – in other words, our engineering, market insight and

creative problem-solving – will remain based at Schlierbach.

As STAMA's new

Managing Director, Mr. Ulmer, what do you consider to be your most important

and pressing task in the near future?

With the technology and staff at Neuhausen ob

Eck, we have the ideal foundation for delivering our proven machine quality.

From a logistical and organization point of view, it's certainly not going to

happen by itself, but all the division managers at STAMA and CHIRON are

prepared accordingly. Alongside managing this relocation process, I think that

an equally important challenge will be to bring out the STAMA Sprit. While a

brand thrives on its products, it really prospers from its staff's belief in

its products. All employees of the CHIRON Group must be aligned with this and

be motivated so that our customers, technology partners and suppliers are still

justified in placing their trust in us.

And just one

personal question to finish with, can you plan for everything in life or should

you just go with the flow?

I think it's right and important to have a

plan. If you have a plan, that also means you've got a goal! If things happen

that are outside your control, you will need to change the plan as needed.

Anyone with a family or children knows that you need to constantly adapt to new

situations. But, ultimately, it's a question of attitude, and mine always tends

to be a positive one. (The last question was answered with a smile.)