In 2018, 48% of all of the project machines CHIRON supplied came

with automation, while this figure reached 55% in 2019 and will be 75% by the

end of 2020. There is a clear trend towards automation, which is continuing to

gain momentum during the COVID-19 pandemic. This is because it will only be

possible to maintain productivity, while also reducing working hours and

staggering work with few operators, by using largely autonomous machines.

For autonomous production, the CHIRON Group provides solutions for

a wide range of requirements with perfectly matched complete packages comprising

a machining center and automation. The most recent example is the combination

of the CHIRON DZ 16 W with the compact VariocellUno automation unit. This means

that there is now also a tailored solution for the 16 Series with various

options – all from a single source.

»Why add the VariocellUno as a further automation solution for the 16 Series? It's quite simple. As is already the case with other series, we wanted to offer our customers an appropriate standard solution for series production which can be perfectly tailored to the production scenario thanks to the different options.«

Kristoffer Siegmann

Head of Global Account Management Automotive at CHIRON Group

Autonomous unit: DZ 16 W and VariocellUno

VariocellUno has

already been used in CHIRON 08, 12 and 15 Series machining centers over 350

times around the world. When used in conjunction with the machine, it brings

clear productivity gains. The experts from the automation department, headed by

Thomas Marquadt, have now further developed the compact unit, which comprises a

handling robot and workpiece store, for the 16 Series.

Visitors to the

OPEN HOUSE ONLINE could already observe the new variant on the DZ 16 W.

Particularly for plants with a workpiece changer, the VariocellUno provides

clear added value with respect to loading and unloading blanks and finished

parts during machine operation. In addition, the robot can perform additional

tasks during the machine runtime, such as cleaning, labeling, deburring and

reading codes. Designed for series production, the VariocellUno automation unit

allows users to manufacture a large number of workpieces in very short cycle

times. Whether for autonomous production at weekends, for night shifts, with

reduced personnel during the COVID-19 pandemic or due to a lack of specialist

staff, the automation unit enables high flexibility while consistently

producing the best manufacturing quality. Indeed, this not only applies to the

16 Series but also to other CHIRON series and the STAMA MC 531 machining

centers.

The combination of the CHIRON DZ 16 W with the compact VariocellUno automation unit enables maximum productivity thanks to its capacity to manufacture large numbers of workpiece in very short cycle times.

The workpieces are

handled by a six-axis robot on the DZ 16 W. The draw storage, palletizer or

workpiece conveyor belt act as a storage medium, depending on the requirements.

In addition, components can be added to VariocellUno according to the

application. These components include multiple grippers and also stations for

turning, measuring, washing and labeling. A large rotating door makes the

machine's working area very easy to access. The automation cell can be moved

for set-up and maintenance tasks which require direct access from the front.

If a DZ 16 W is

already in use, the new VariocellUno can be added without any difficulty. It is

also possible to implement the VariocellUno on 15 and 18 Series machining

centers – whatever approach is taken, customers are ably supported by the

CHIRON Group's automation experts.

VariocellUno: Many

advantages in one compact unit

High degree of utilization for increased profitability

Attractive value for money

Replacement of blanks and

finished-part pallets during machine operation

Machining center and automation from a single source

Storage medium depending on the requirements

Easy to operate and program

Best access to

the working area for cleaning and maintenance tasks

Greater flexibility and dynamism: FZ/DZ 16 with

VariocellPallet

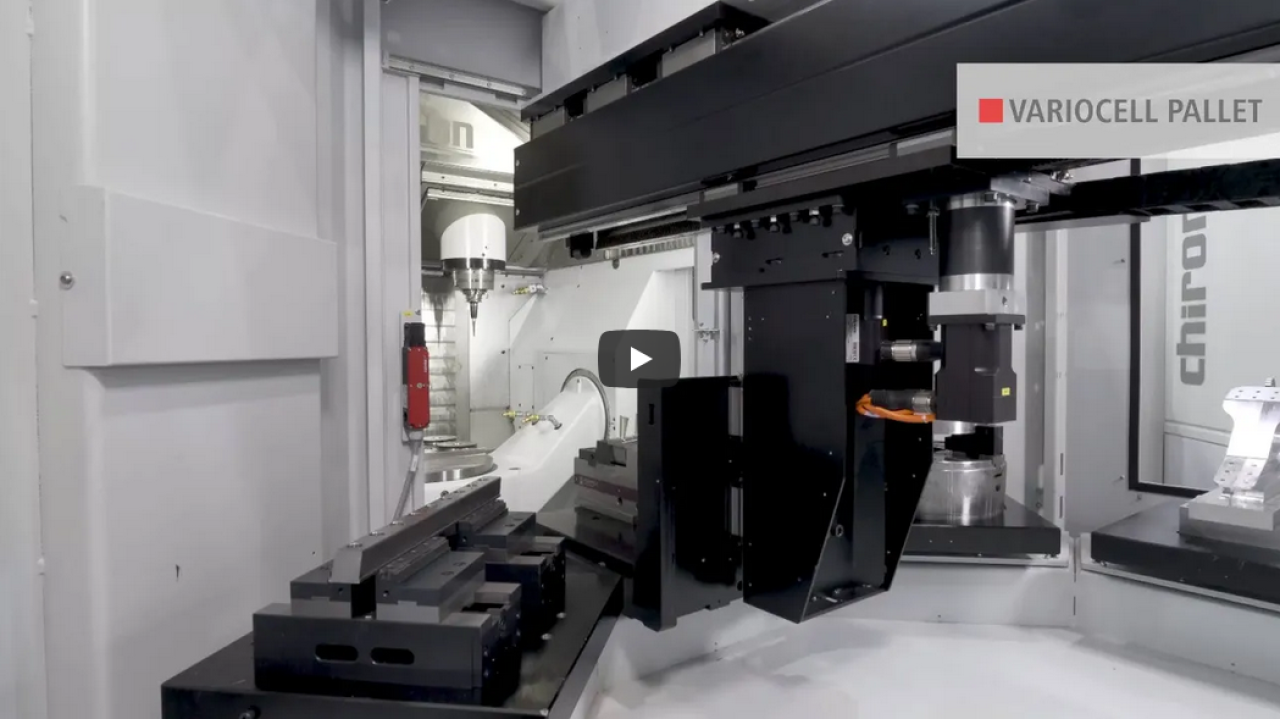

The CHIRON Group already showcased the first

pallet automation in its range at OPEN HOUSE 2019. This innovative solution

gives the 16 Series single-spindle machines greater dynamism and flexibility

when machining small batch sizes and complex workpieces, as well as when

manufacturing individual parts with long machining times.

Various blanks are

clamped on a rotary indexing table with up to ten prefabricated pallets. The

handling system supplies the machining center with blank after blank and

removes the workpieces together with the pallet following the successful

machining process. This significantly increases productivity. Another advantage

is that while one pallet is being machined, a second can be loaded at the same

time.

With its combination of the CHIRON FZ 16 S five axis and the VariocellPallet automation solution, small batch sizes and complex workpieces can be machined autonomously and with high flexibility.

The motorized transfer trolley with rollers is a major

advantage with respect to having easy access to the VariocellPallet, even in

confined spaces. The trolley can be moved in three directions without rail

systems and, if required, can also be manually loaded and unloaded.

As unique as your manufacturing tasks: VariocellSystem

As an alternative to VariocellUno and VariocellPallet,

the 16 Series machines – as is the case with all CHIRON and STAMA series – can

be fully automated and customized with the relevant modules. The

VariocellSystem is the perfect fit for all specific requirements – whether for

handling systems, gantry or articulated arm loaders, workpiece stores for

blanks and finished parts, pallet stores, feeding or discharging equipment or

peripheral units for cleaning, identification, testing or measuring.

»We know our machining center interfaces better than anyone and can get the most out of our customized automation systems' dynamic advantages for our customers. We make every robot automation system ourselves – and we're very proud of this. «

Thomas Marquardt

Head of Automation at CHIRON Group