Overview of maintenance

strategies

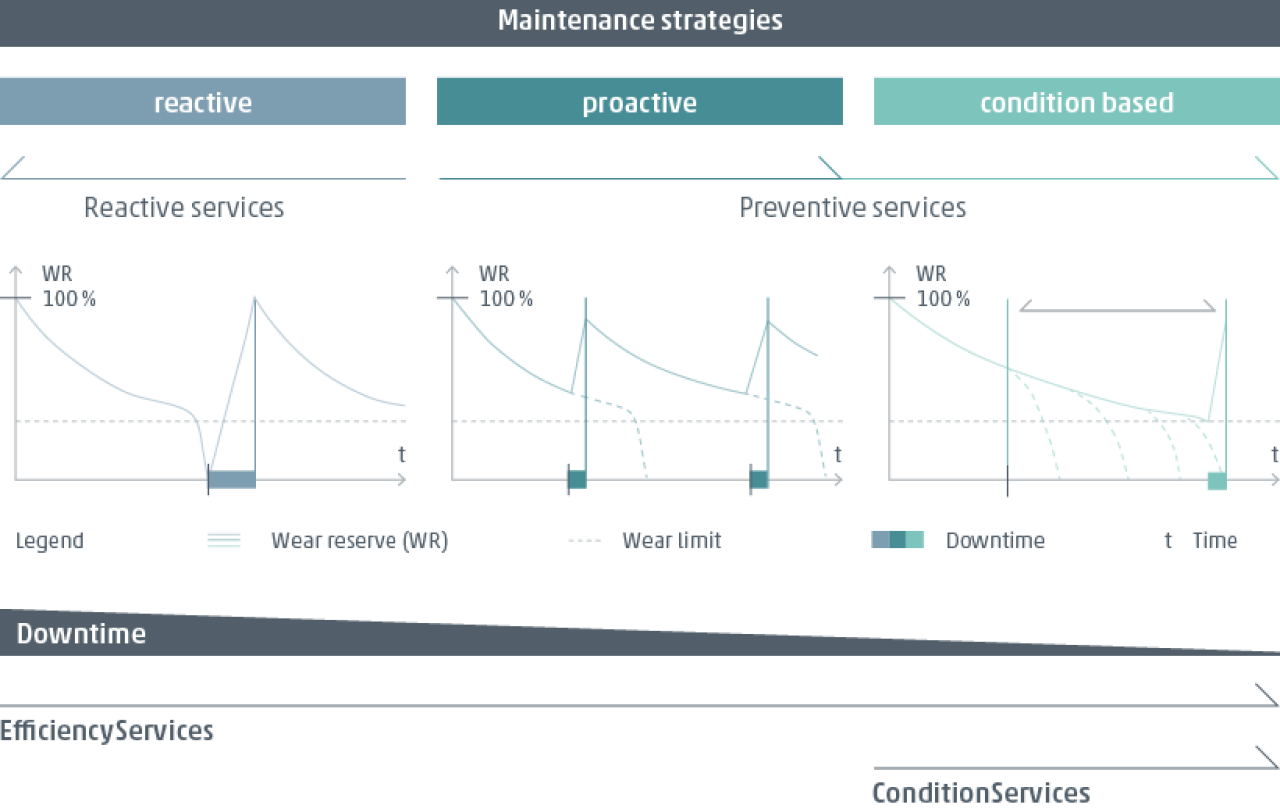

»Reactive«, »proactive« and »condition-oriented« are three strategies

used for machine maintenance. Many companies still choose a reactive strategy,

only taking action once a fault has already occurred. This will affect machine

availability accordingly – the more complex the fault, the longer the period

during which machining center will be unable to manufacture.

EfficiencyServices

enable improved reactive maintenance with reduced downtime. Using RemoteLine,

which provides direct access to the machine data, the experts at CHIRON Group

Service can identify and resolve faults, in many instances directly and without

making a service call-out. When combined with proactive, cyclic maintenance,

this can further reduce unplanned downtime.

However,

it will take additional measures to increase machine availability in the long

term. Namely, a long-term strategy to reduce downtime towards zero and to

consistently maintain the machine in its best condition. This is where

ConditionServices come in.

ConditionServices: A

three-step strategy

ConditionServices

are not a one-off solution but rather a long-term process towards consistently

high technical availability – with the additional benefit of fixed, foreseeable

costs.

Step one: Analysis of the

machine and service history

To

start with, the service managers take a look back and closely inspect the data

of all of the components which influence the manufacturing quality. Which

faults have there been in the past?

Have

certain components – as illustrated in the figure by the tool changer and

drivetrain on the Y-axis –

been disproportionately affected? The service managers look into the details of

any abnormalities, research their causes and recommend how such a fault can be

avoided in future. For example, this could involve retrofitting or adapting the maintenance

plan to the tool changer with an enhanced wear parts package.

Step two: Cyclic recording and

data evaluation

In

the next stage, all potential sources (new and existing CHIRON and STAMA

machines) are incorporated into a comprehensive maintenance strategy based on

ConditionLine, a module from the SmartLine range. The digital system

automatically analyzes all of the machine data that is relevant for the machine

to operate reliably.

ConditionLine

is directly integrated into new machines. On the other hand, existing CHIRON

and STAMA systems can be upgraded with hardware and software via a retrofit.

For older machining centers which do not have the technical prerequisites for

integration or continuous data recording and evaluation, HealthCheck is the

correct instrument to use. HealthCheck adds additional appointments to the

annual maintenance schedule so that the CHIRON Group Service can manually

inspect the machining centers on-site. The managers use the results to make

well-founded recommendations for maintenance work and to exploit optimization

potential.

Step three: Maintenance based

on the machine condition

ConditionLine

constantly monitors and analyzes the condition of the machine and detects

irregularities in operation at an early stage. The more machines that are

integrated, the less time it will take to create a comprehensive, reliable

database. Another factor is time. This is because, with every passing month and

year, potential disruptive factors can be predicted with greater accuracy. The

maintenance scope and planning can therefore be adjusted to the current

requirements in an accordingly dynamic and increasingly precise manner.

Technically availability will rise increasingly, with the additional benefit of

fixed and foreseeable costs.

Buy or subscribe?

With

ConditionServices, customers have a choice of different payment models. The

ConditionLine software and necessary hardware can be purchased in the

traditional way via a retrofit, or a subscription can be taken out for the

contract term.

In

addition to ConditionLine and/or HealthCheck, the following services are

included in all price models: Analysis, inspection and maintenance of the

machining centers, as well as spare and wear part replacement.

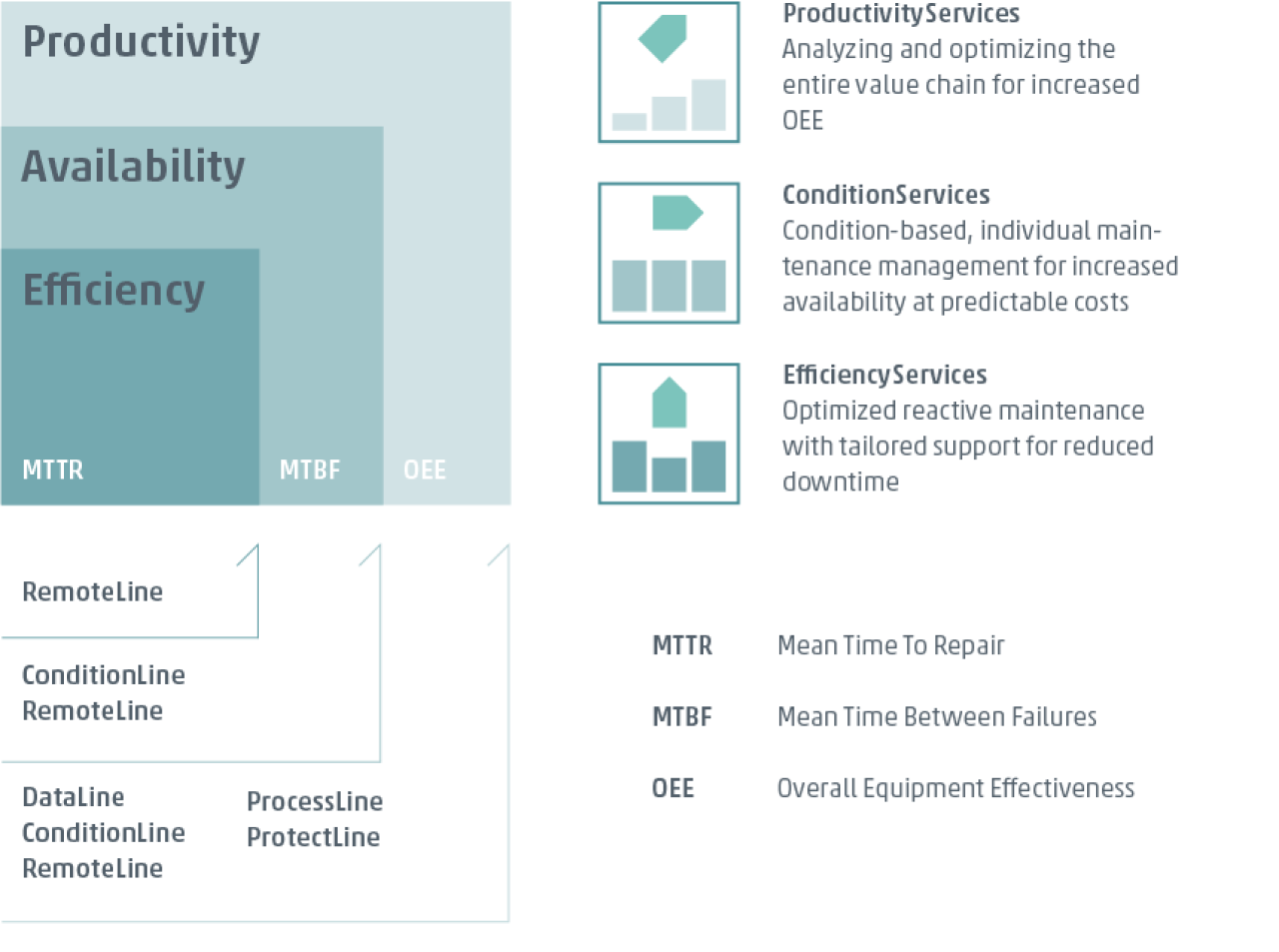

Improving performance by

combining modules

The

third element for increased overall equipment effectiveness are

ProductivityServices.

In this case, the service

managers scrutinize the manufacturing process, including all of the areas

involved such as hardware and software, automation and process and set-up times.

This indicates any areas of untapped potential and these can be exploited using

appropriate measures, particularly by integrating additional SmartLine modules.

Want

to find out more about SmartServices?

Johannes Hellstern, Digital

Services Product Manager at the CHIRON Group, would be happy to answer any

calls or e-mails.

Johannes

Hellstern

Phone:

+49 7461 940-3728

[email protected]