The shift in manufacturing processes is placing higher

demands on production technology, for example with complex hybrid drives,

lightweight construction of vehicular and structural components, battery trays

and more efficient combustion engines.

Machining processes must be as dynamic as they are precise

and it must be possible to configure the machining centers flexibly in line

with specifications. All the better if the entire process is easily accessible

and easy to see. Or you could simply opt for the DZ 28.

The right model

for every application

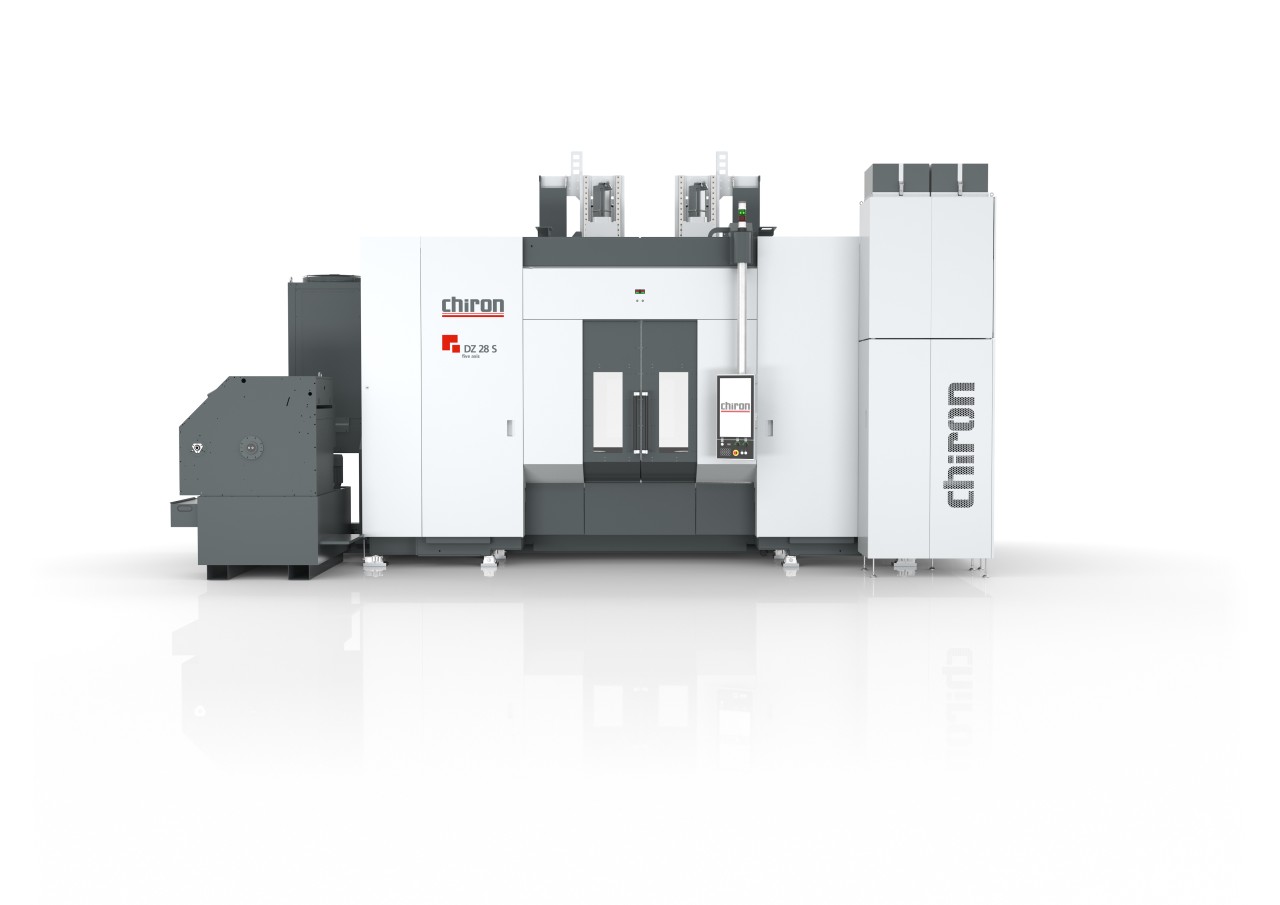

The new series is available in two machine variants, the DZ

28 P five axis – P for pallet changer – for high quantities and short cycle

times, or the DZ 28 S five axis – for direct loading. The new series will be

available to order from 2021.

»With the 28 Series, we are addressing new customers and workpieces. Whereas previously, components of this size could only be used for single-spindle manufacturing, the new DZ 28 twin-spindle machines have considerably shorter cycle times – while also producing the best part quality.«

Kristoffer Siegmann

Head of Global Account Management Automotive at CHIRON Group

Grand in all

respects, except for its launch.

Kristoffer Siegmann is satisfied with initial feedback from

the market. »We got a very encouraging response from our customers.

Completing our range is exactly the right way for us to go. The market wants to

see machines which effortlessly manage extremely high quality requirements –

like thin-walled components as well as high form and positional

tolerances.«

| X-Y-Z travel distances |

Max. 1,200–1,100–800 mm |

| X-Y-Z rapid traverse speeds |

Max. 120–75–75 m/min |

| Spindle clearance |

1,200 mm |

| Tool holder |

HSK-A63 |

| Workpiece diameter |

1,200 mm |

| Workpiece height |

Up to 750 mm |

| Palette size (for P variant) |

800 x 800 mm |

With a spindle clearance of 1,200 mm, the new DZ 28 is

predestined for five-axis machining, for example for integral supports,

longitudinal supports, large suspension holders, battery cases for hybrid

vehicles and housings for power electronics.

The operating and loading sides are separated. The working

area is always easily accessible and the process easy to see.

Loading and unloading side of the DZ 28 S five-axis

Operating side of the DZ 28 S five-axis

Other major advantages include the flexible machine layout

with a small footprint, high dynamics, spindles which can be moved fully

independently on the Z and X axes and its automation via robots or gantry. The

machining center is operated using TouchLine, the established operating system

from the SmartLine range. The machine condition can be monitored at all times

on the large panel.

A

tried-and-tested machine concept in a new size

A platform in a portal design forms the basis of the

machine concept with a small footprint from 30 m2.

The rigid machine bed and active component cooling enable the required degree

of precision on the workpiece. High axis acceleration and fast rapid traverses ensure

dynamic machining as never before seen with workpiece dimensions of this size.

The machine concept is also very flexible. Whether machining complex workpieces

with many tools or workpiece families – the two magazines offer space for up to

60 tools and therefore

mean minimum set-up for manufacturing. Workpieces are loaded and unloaded

during machine operation.

Unlock the full

potential: With SmartLine

As with all of the CHIRON Group's new series, the 28 Series is prepared for

integration of all SmartLine modules. For example, this includes ProtectLinefor preventive protection against machine crashes and ConditionLine for

automatic condition monitoring of relevant machine components.

Want to find out more the new size for precise and dynamic

machining? Kristoffer Siegmann, Head of Global Account Management Automotive,

would be happy to answer any calls or e-mails.

Kristoffer Siegmann

Phone: +49 (0) 7461 940 3074

[email protected]

E-mobility:

Technology with a history?

It is not just in recent

times that the e-mobility sector has been booming. Around 1900, there were

34,000 electrically powered vehicles on the roads of the USA. Read on to find

out more about how this sector has since developed in a brief history of

e-mobility.

Brief history

of e-mobility

You would do well to remember Michael Faraday when you are

driving your car through a storm – his electric cage means that you are

protected against any lightning strikes. Faraday was a natural scientist and in

1821 he proved how electromagnetism could be used to generate continuous

rotation, the starting point of e-mobility.

Scottish inventor Robert Anderson created a form of

electrical carts, which was followed by his invention of an electric vehicle in

1839. Robert Davis, another Scotsman, was the first to invent an electrically

powered vehicle for rail tracks.

American Charles Grafton Page came up with the idea of

creating an electrically powered locomotive. This vehicle reached speeds of 31

kilometers per hour on a test run.

The invention of a chargeable lead-acid battery marked an

important step in e-mobility, and it would go into production the very next

year.

Camille Faure improved the lead-acid battery, coating the

lead plates with a mixture of lead sulphates. This greatly increased the

battery's capacity. Faure's battery is the reason why Paris is known as the »City

of Light«, as it had the first street to be lit by electric lighting.

The Ayrton and Perry electric tricycle caused a great stir

on London's Victoria Street. The joint invention by William Edward Ayrton and

John Perry had a fully electric drive and could travel up to 40 kilometers at

up to 14 km/h on a single battery charge.

The first electric car, the Flocken

Elektrowagen, was manufactured in Germany. Visually, the model with its cabin

looks more like a carriage.

At the world exhibition in Paris, Ferdinand Porsche entered the public spotlight with an

electric car he had designed while under the employment of Jacob Lohner at the

Lohner-Werke firm. The "Lohner-Porsche" had front-wheel hub-mounted

motors. He also gave a lot of thought to what would potentially be the car's

small range. This is why he included a mixed-use electric and combustion

engine.

Approximately 34,000 electrically powered cars were on

American roads, some of which had impressive ranges of 100 kilometers or more.

Between 1896 and 1939, there were 565 manufacturers of

electric vehicles around the world. In Germany, this included brands such as

Siemens, Hercules, Kühlstein and the Fahrzeugfabrik Eisenach.

»Within a year, I hope, we shall begin the manufacture of

an electric automobile,« said Henry Ford in an interview with the New York

Times in January 1914.

Following a long break, Ford showcased a pure all-electric

prototype in the form of the »Ford Comuta« microcar. The model had 12 V

batteries, a range of approximately 60 km and a top speed of 55 km/h.

In the United States and, particularly the United Kingdom,

milk bottles were delivered to customers' front doors each day by electrically

powered milk floats.

The oil crisis brought about a real change in thinking.

There was an increasing awareness of environmental issues and alternative

drives came back to the fore. In addition, the Californian government passed an

act to encourage the automotive industry to innovate and to switch its car

production to emission-free vehicles.

The Horlacher Sport I concept vehicle traveled a record

distance of 547 kilometers on a single battery charge.

VW constructed the Citystromer, a variant of the VW Golf II

and III converted into an electric vehicle.

An example of particularly innovative work is the

Hotzenblitz model, manufactured between 1993 and 1996 in the city of Suhl in

the central German state of Thuringia. The two-person vehicle was developed in

the south-western German region of Hotzenwald and, at the time, was the most

consistent electric car in Germany.

Tesla showcased its Roadster at the Santa Monica Airport in

California. Small series production would begin in March 2008. By 2012,

approximately 2450 models of the two-seater sports car had been manufactured and

sold all around the world.

Nissan released the »Leaf«, the first large series electric

car designed exclusively for this type of drive. With its various models and

cumulative sales of 450,000 units (as of January 2020), the Nissan Leaf is the

world's bestselling electric vehicle.

Germany celebrated 125 years of e-mobility production and

BMW presented the BMW i3, a plug-in hybrid in the small car class and the first

production vehicle with a passenger module made from carbon fiber reinforced

polymer (CFRP).

Volkswagen brought the ID.3, the first model in the ID

family, onto the market. The modular electric drive kit (MEB) would also be

used by Audi, Skoda and Seat.