In the medical technology sector, very high

precision is often still achieved manually by an experienced surgical

technician or by using a complex machine with multiple machining steps.

However, in light of increasingly sophisticated workpieces, increasing

quantities, higher risk categories and more stringent traceability requirements

for medical products, a new approach is required. These factors mean that it is

necessary to switch to productive, validated CNC processes which enable

high-precision complete machining and ensure maximum, reproducible precision

and surface finish from one part to the next.

View of the Medical & Precision Technology Center.

A center for

precision and special turnkey expertise

In 2013, the CHIRON Group pooled the advanced

expertise it had developed in this field over decades at the Medical &

Precision Technology Center in Tuttlingen, a town in south-western Germany. The

on-site team creates a customized manufacturing solution for every project.

Employees also provide customers with the turnkey expertise required for an

"overall package" ready for production with perfectly coordinated

technology modules. This not only includes machining centers by CHIRON, STAMA

and FACTORY5 (the Group's recently acquired brand) but also covers tools,

holding fixtures, automation, the CAM system and much more besides.

Turnkey expertise

for medical and precision technology

Comprehensive process design, including

machine recommendation, tool design, clamping concept and program creation

Skilled engineering, experienced project management

Validation of statistical process capability

Assurance of target productivity

Production support during the initial phase

Customized automation

Training sessions for optimal use of the

manufacturing solution

Tailored services over the entire life cycle

The approach taken by the specialists at the

Medical & Precision Technology Center is unique, says Martin Brenndörfer,

Head of CNC Application Technology for Medical and Precision Components at

CHIRON.

»Customers in the medical technology sector aren't just buying a machining center, they want to see the complete manufacturing process for their product on the machine beforehand. Ideally, it needs to work so well that we can disassemble the system straight away and put it back together again at the customers' premises.«

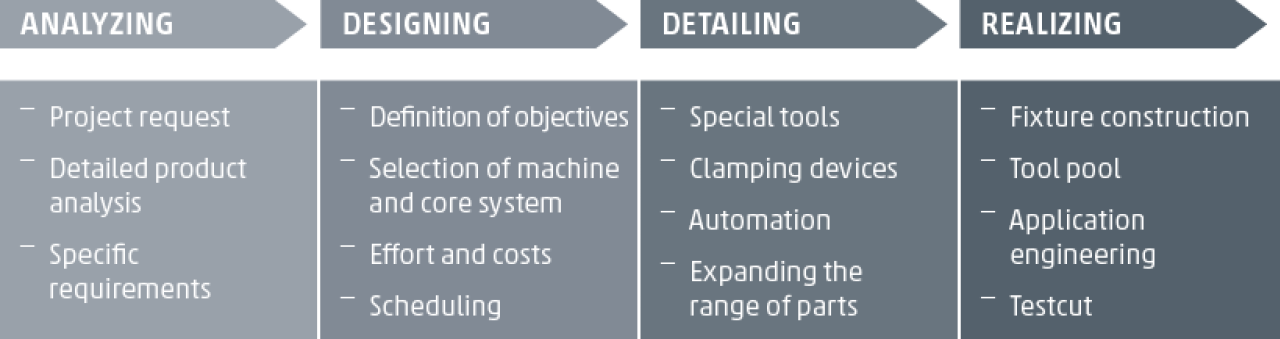

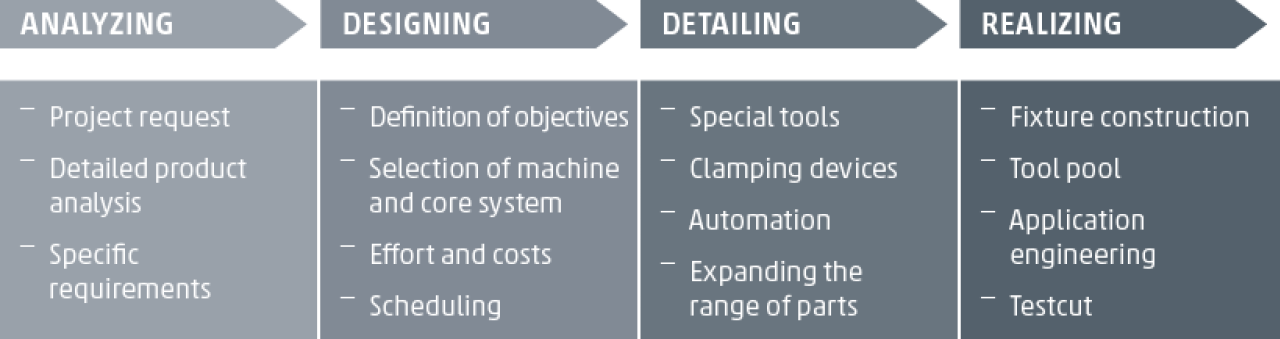

To achieve this, every project at the Medical

& Precision Technology Center goes through the following four steps: Analyzing,

designing, detailing and realizing.

Benefit from a coherent process.

Benefit from a coherent process.

The key to finding the best turnkey process for

each situation is to have precise answers to a number of questions. To list

just the most important ones:

Which of the

requirements are the special requirements?

Which machine is

suitable for the application?

Which colleague

can offer expertise in the relevant area?

Do we need any special tools, such as specific clamping equipment?

Which parts from the customer's range can also be positioned on the manufacturing

solution?

The

next issue of speedfactor will share the answers given by the team regarding

the specific requirements of Carl Teufel GmbH & Co. KG, a manufacturer

based in the town of Emmingen-Liptingen in south-western Germany. To give you a

brief preview: Rather than machining high quantities of finished goods for

surgical micro instruments (such as spring scissors, needle holders and

forceps) in multiple machining steps, as was previously the case, they are now

completely machined on a FZ 08 S mill turn with Precision+.

#medicalwednesday

On 💊✌️💉 Medical Wednesdays, we use the hashtag

#medicalwednesday on the CHIRON Group's

LinkedIn and Instagram accounts to share excellent new tools, exciting projects

and much more besides.

Here are a few examples for »maximum precision«: