Author: Oliver Ehm

Published with kind permission of the company Gebr. Märklin & Cie.

»Our products are still

synonymous with diecasting,« says Jochen Gaißert, Production Planner at

Märklin. »It's of great importance to us because diecasting produces unrivaled

tactile properties and quality. The material is relatively

heavy and ideally suited to the properties of model railways.«

The expert adds

that another advantage is that this material is easy to machine, process and

coat, and has many excellent properties for model railways. In particular,

diecasting is very heavily used in locomotive production – primarily in the

structure and chassis sections. »Ninety-eight percent of all diecast parts we

process in our models are produced here at our foundry in Göppingen,« Gaißert

explains. »We buy in the remaining parts, such as the drives, since their size

means that we can't manufacture them ourselves.« Based in the town of Göppingen

in south-western Germany, Märklin brings together all of the manufacturing

technologies required to build a model railway. These include tool and mold

making, diecasting, injection molding, turning, gear manufacturing,

electroplating (nickel-plating), coloration, punching at a small facility,

assembly and quality assurance. Göppingen also supplies the subsidiary plant in

Hungary with parts, which are then colored and assembled on site, Gaißert adds.

A 36-year

partnership

In 1984, Märklin acquired its first CHIRON CNC machine

– an FZ 16. For the long-established company, this was also its first step

towards complete machining in the chassis area of the locomotives. At the time,

Märklin's employees in Göppingen still produced the drives themselves, with the

processes of chassis and gear machining forming a key production area. Märklin

approached CHIRON in the early 1980s because, Gaißert explains, the

Tuttlingen-based machine manufacturer was the only supplier which adapted multi-spindle

heads and achieved process times which went beyond what the conventional

machinery could achieve with respect to cost-effectiveness. »From an economic

point of view, we'd never have gone in that direction otherwise,« Gaißert

believes. »The CHIRON machines still stand out today thanks to their very short

downtimes and, at our company, we're always performing a lot of tool

changeovers and machining operations.« While Märklin also considers other

manufacturers from time to time, Gaißert states that the downtimes and machine

design are exactly what Märklin needs for its applications.

»For many years,

it's been obvious that we're very likely keep going with CHIRON machines. We

also benefit from the partnership when a new machine series comes out – particularly

when the FZ 08 was released and the company representing CHIRON at the time let

us observe the machine at another business before it came on the market,« Gaißert

sums up. »We then bought a machining center shortly after it was launched.« The

managers at Märklin think highly of CHIRON's proactive dedication. »Together

with CHIRON, we've adapted our interfaces and equipment as part of a major

project. CHIRON was very heavily involved. They even adapted the machine design

especially for us,« Gaißert remembers. »What's more, the machines are very

reliable, stable and operate with high precision.« There are also pragmatic

reasons for Märklin's decision to continue purchasing CHIRON machines.

»There

are great advantages to homogeneous machinery. The variety in control systems

is manageable, the supply of spare parts is excellent and our employees are

included in this approach. They know how CHIRON operates and if there's ever a

real issue, their servicing and programming support is outstanding,« Gaißert underlines.

»For a competitor to come close to us, they'd need to offer significant

advantages.« Märklin tries to avoid having an unchecked variety of machines

from different manufacturers. This is because, in terms of organization, it

would be difficult to manage heterogeneous manufacturing machinery. Under

certain circumstances, you would need to use different tool systems or

measuring technology and this would, in turn, drive up costs. Gaißert adds that

Märklin also once internally considered the merits of STAMA, another brand in

the CHIRON Group, before deciding against it.

This was because, when compared

with STAMA's wheel change concept, CHIRON's pivot holder and chain tool change

concept offered advantages with respect to interfering contours. Märklin last

purchased a machine in 2014. The machining centers have a service life of

around 20 years when operated for two shifts, five days a week.

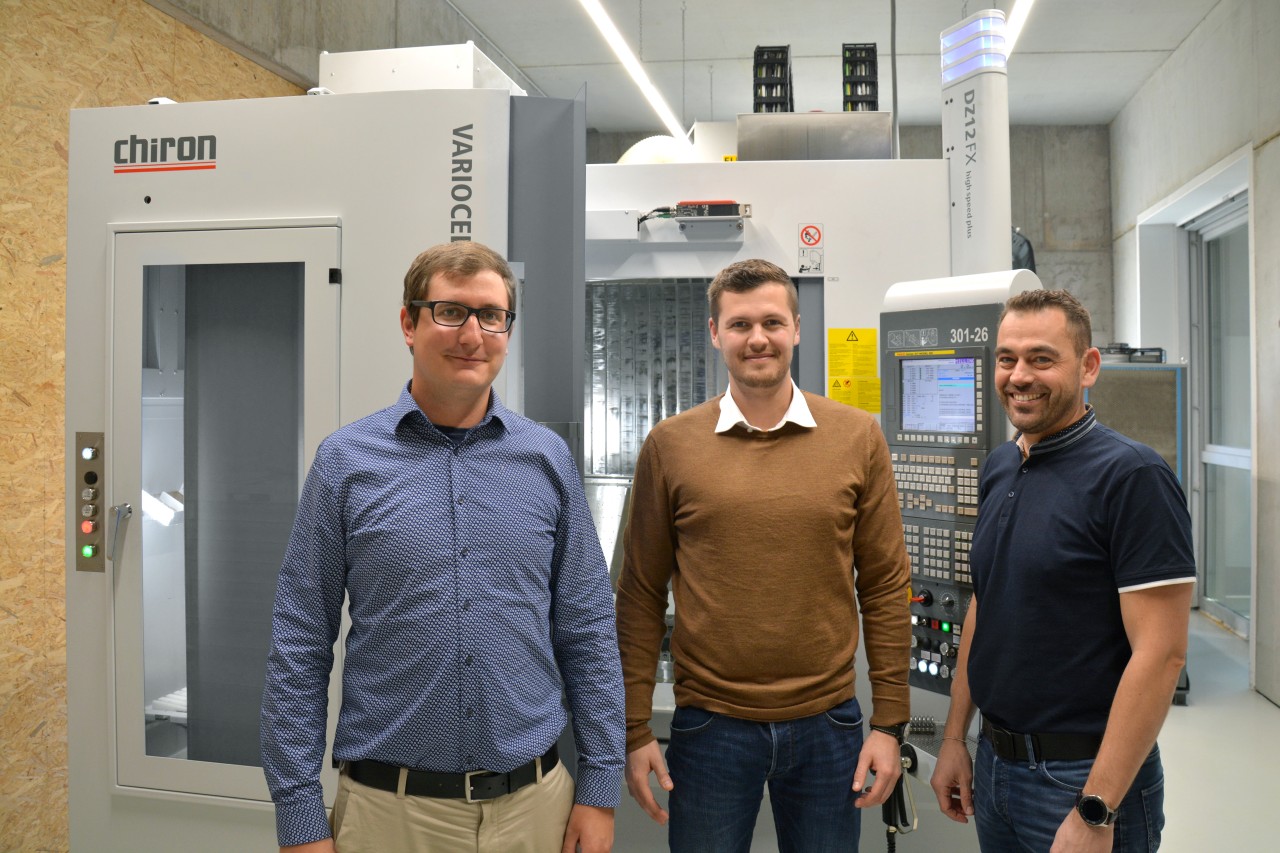

36-year partnership between Märklin and CHIRON (from left to right): Sven Dannenmann (Head of Diecasting and Cast Iron Machining at Märklin), Jochen Gaißert (Production Planning at Märklin), Bernd Hechler (Technical Consultancy/Sales at CHIRON) and Michael Patschkowski (Production Machine Setter at Märklin). Image source: Oliver Ehm

Modernized production

In the meantime, Märklin's main area of production has

changed again. The Göppingen-based company currently has a total of six

machining centers – three FZ 08 models, two FZ 08 models and one FZ 12 model –

primarily for producing the structural and locomotive housing. The business now

uses industrial motors for its drives. While these are bought in from

elsewhere, they significantly improve the level of detail in the structure and

locomotive housing sections. The experts at Märklin say that this results in

the constant challenge of finding a middle way between what is possible from a

casting perspective or what is only possible with a great deal of effort, and

what can subsequently be achieved more cost-effectively using a machining

center.

»We're now using a fourth generation of machines from CHIRON.

Everything is going very well and our partnership is working perfectly,«

Gaißert explains. He particularly emphasizes the quality of support provided

for process time generation and feasibility studies, adding that test machining

operations are also possible. »Two years ago, we were at CHIRON's premises

because we wanted to try something new – we milled a semi-finished product into

an undercarriage. We first programmed it here and made various attempts, but we

weren't fully satisfied with the outcome,« remembers Sven Dannenmann, Head of

Diecasting and Cast Iron Machining at Märklin. »We then approached CHIRON and

they redesigned the program and produced samples.« Gaißert adds, »At the time,

this production set-up was uncharted territory for us. While we did have a

five-axis machine, we only used it for positioning because we needed to make

holes at suitable angles. For this project, we wanted to mill a solid block

into an undercarriage for the small Z track gage, which was something we'd

never tried before.« Dannenmann continues, »If we are working on a new product

in-house during the design phase and our experienced on-site specialists are

reaching their limits in terms of technical manufacturing, we contact CHIRON

and know that we'll be supported by a skilled partner.«

Bernd Hechler,

Technical Consultancy/Sales at CHIRON, states »Development is 100% in Märklin's

hands; CHIRON is only brought in if it there are applications where our

specialists need support.« As one of the greatest challenges for Märklin is

making its products as realistic as possible, the departments involved in

development and production are included in order to recognize and resolve any

problems at an early stage.

Depending on the part interdependencies, Märklin

produces between 80 and 200 housings and attachments a day. The runtimes for

each part can vary considerably, depending on the parts' complexity due to

their features and details. »Sometimes a part like this can take up to four

minutes,« Gaißert explains. »But there are also simple workpieces which can be

made in 30 seconds.«

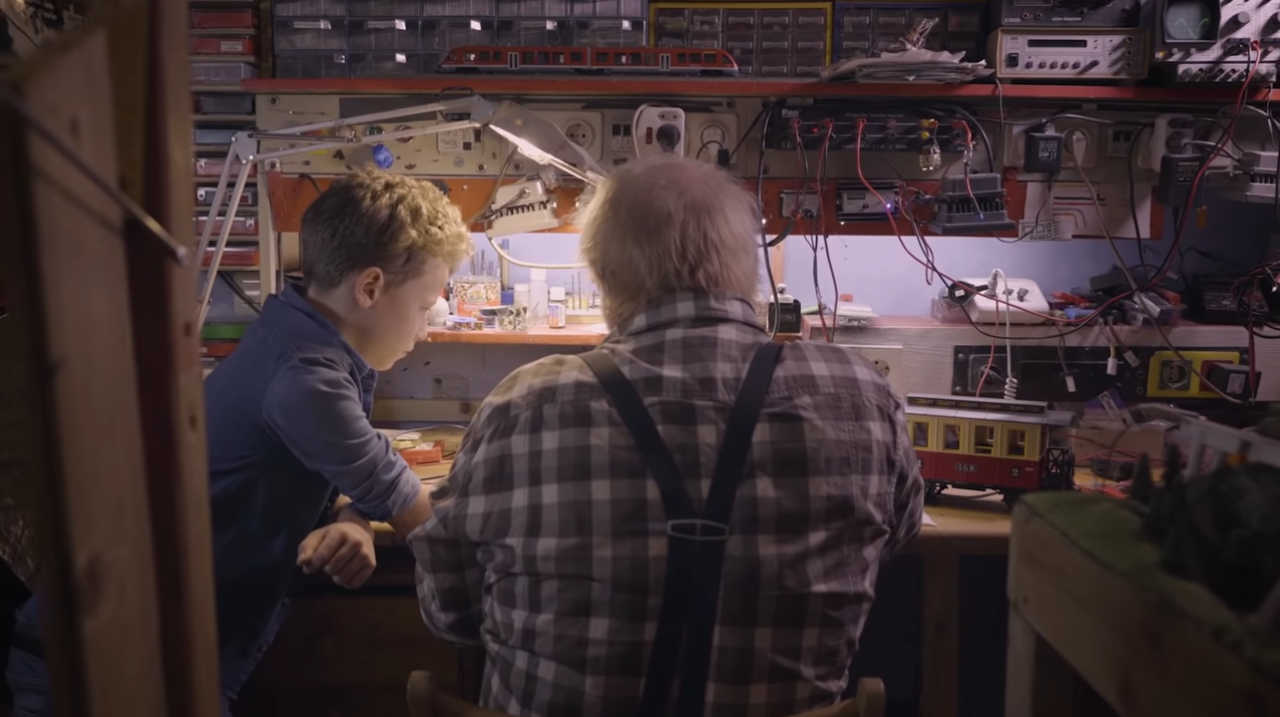

Image Source: Oliver Ehm

Image Source: Oliver Ehm

Image Source: Oliver Ehm

Plans for automation

However,

Märklin has experienced difficulties when it comes to automating its production

facilities. This is primarily because the company machines a wide range parts

and therefore the process of automating the machinery is very complex. »There's

already automation in the form of a brush robot, which machines many – but not

all – of the housings,« says Dannemann, Head of Diecasting and Cast Iron

Machining at Märklin. But ideas are being considered for gradually automating

production. With the assistance of CHIRON, the experts at Märklin are looking

for ways to advance automation in order to further increase the profitability

of its business operations.

Gaißert says that Märklin produces a relatively high

number of new products every year – like the current »TEE Edelweiss«, a

four-carriage train with all of its attachments made from diecast metal. »Model

train collectors expect new innovations at regular intervals. They must all

pass through production in a timely manner and on schedule,« states Gaißert. »This

entails a great deal of effort in preparation, as the partner parts must

interact perfectly and we machine a large number of high-precision items.«

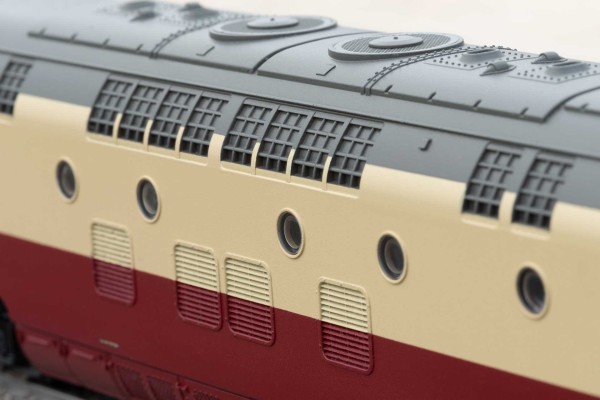

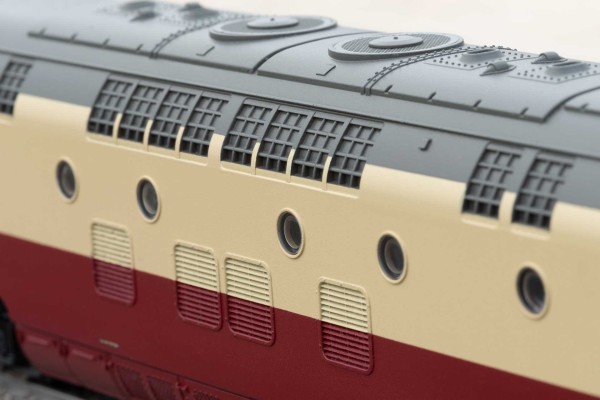

The »TEE Edelweiß« of Märklin. Image Source: Märklin

Image Source: Märklin

Image Source: Märklin

On top of

this, the company also produces classic locomotives. »We've still got a lot of

molds from the 1950s and 1960s which we continue to use in production today,«

Dannemann notes. »These locomotives are known as replicas.« When Märklin

releases a new locomotive model, it often also offers the old version at the

same time so that collectors have the option of purchasing both. »While the

interiors are fitted with brand new technology, the design is the same as the

old model's and has all of its characteristics – such as fewer details and

attachments,« Gaißert explains. »But that's exactly what makes them so charming

and appealing to customers and prospective buyers.« However, just because these

models do not have a modern design, this does not mean that they are easier to

machine. In fact, they are usually more time-consuming because their mold and

tools are technically inferior to modern designs and, therefore, a great deal

more manual work is required.

In the

medium term, Märklin plans to replace its four-axis FZ 08 W with a five-axis

machine. This modernization will increase cost-effectiveness because complete

machining will lower the costs for equipment and set-up and also reduce the

potential for errors. »Our experience with the five-axis FZ 12 has shown us

that this is the right way to go,« says Gaißert. »It would mean that we'd no

longer be working with a conventional workpiece changer but instead undertaking

complete machining with the five-axis machine. This would also increase

flexibility in production.« Each new model brings one-time costs for molds,

equipment and tools and you therefore need to find where you can make savings

in the process. For smaller batch sizes, complete machining is clearly superior

to the workpiece changer setting. Should Märklin ultimately decide to invest in

this replacement machine, the machining center will almost certainly be

purchased from CHIRON once again.

For more information: www.märklin.de