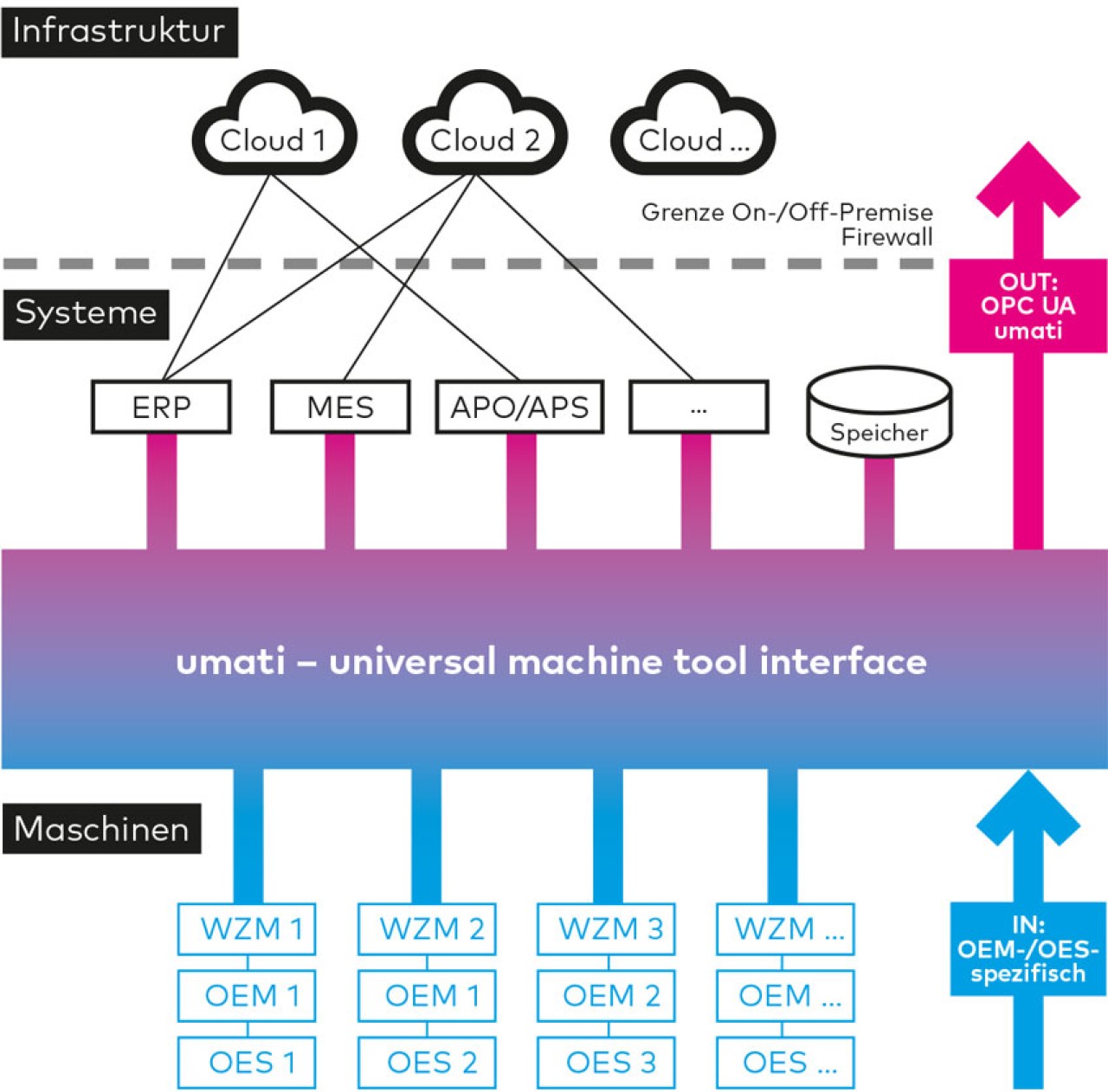

umati: A shared language unites machines

The more easily machines from

different manufacturers »communicate with each other«, exchange information and

use it together, the faster and better the potential for increased productivity

can be tapped. This is precisely why the VDW industry initiative is laying the

foundation with umati. umati is a universal interface, which is establishing

itself worldwide as an open standard for the machine tool industry.