If you get to witness

Fouad Cheaitani, Head of Sales, Customer Support and Business Development at

Stellba, and Axel Boi in a discussion about digital expertise, you feel a bit

like a spectator at a high-level table tennis match. The balls fly at lightning

speed, the »players« are precise and each return brings a new twist. They’re in

their element – a well-oiled team. They’re clearly proud of what has developed

from what was initially a simple LinkedIn connection. It’s grown into a

development partnership and the AM Cube, which, since its premier at the OPEN

HOUSE ONLINE in May 2020, has expanded both its options and applications. One

thing led to another...

Expanding and deepening expertise

As a specialist for

tailored customer solutions for coatings and machining, Stellba has in-depth

expertise in the areas of thermal spraying, welding and Plasma-Transferred-Arc.

In 2014, they had already begun using laser technologies and selling the first

laser-welding systems for »XXL-workpieces and components,« says Fouad

Cheaitani. The goal of the

investment was to optimize the technology for use at Stellba and to transfer

the machining of particular workpieces to the factory. The particular focus was

on the processes where conventional methods delivered good results, but they

weren’t quite »Swiss Quality«.

Building expertise and finding new partners

The company built up its

expertise and, in May 2019, took on distinguished expert Fouad Cheaitani. He

had extensive experience with laser technologies, which he’d been building on

since 2003, precisely tracking the development of laser deposition welding,

especially in Additive Manufacturing, across all media. Fouad Cheaitani gives

lectures on the subject and is well-connected with all specialists and research

institutions in this area.

When Stellba was looking

for a partner to expand their expertise beyond coating to the creating of

workpieces, to answer requests to manufacture small batches, Fouad Cheaitani

was in contact with a whole host of companies. But none of these really

fulfilled his requirements for a partnership that really benefited both

parties. »We didn’t want a finished system that we would need to restructure to

suit our needs. We’re also a relatively small company, with only 20 employees,

and we worried that we wouldn’t be heard on stage with the large OEMs.«

But, thankfully for both sides, Fouad Cheaitani

became aware of CHIRON Group during his research, thanks to how active it was

in the area of Additive Manufacturing. He liked a LinkedIn post by Dr. Nasim

Bosh and immediately made contact. They got to know each other online, then met

in person at the ETH Zurich and found they clicked instantly. The first meeting

with Axel Boi took place in fall 2019, and the contracts had been signed before

Christmas even arrived.

Flexibility. With Additive Manufacturing as an alternative.

Axel Boi was immediately

prepared to prove that they could achieve what Fouad Cheaitani describes as »fantasy

in the plant«. He wanted to work together with Stellba to put the existing

qualities of the AM Cube to the test. They wanted many options which fell under

the heading of »maximum flexibility«. Stellba is a service provider, and the

requests can differ greatly from day to day. For example, machining with four

or five axes, wire or powder, material application with lance or nozzle,

preheating parts to 300 degrees, welding under argon cover gas atmosphere in

the entire working area to avoid oxidation and formation of pores – every

project has its own, new challenges. Challenges, which the AM Cube would need

to conquer fantastically.

»We didn’t want a pre-made system. We wanted our fantasy in the factory, with a variety of options which we, as contract manufacturers, could adjust for the most different tasks.«

Fouad Cheaitani

Head of Sales, Customer Support and Business Development at Stellba

The Highlights:

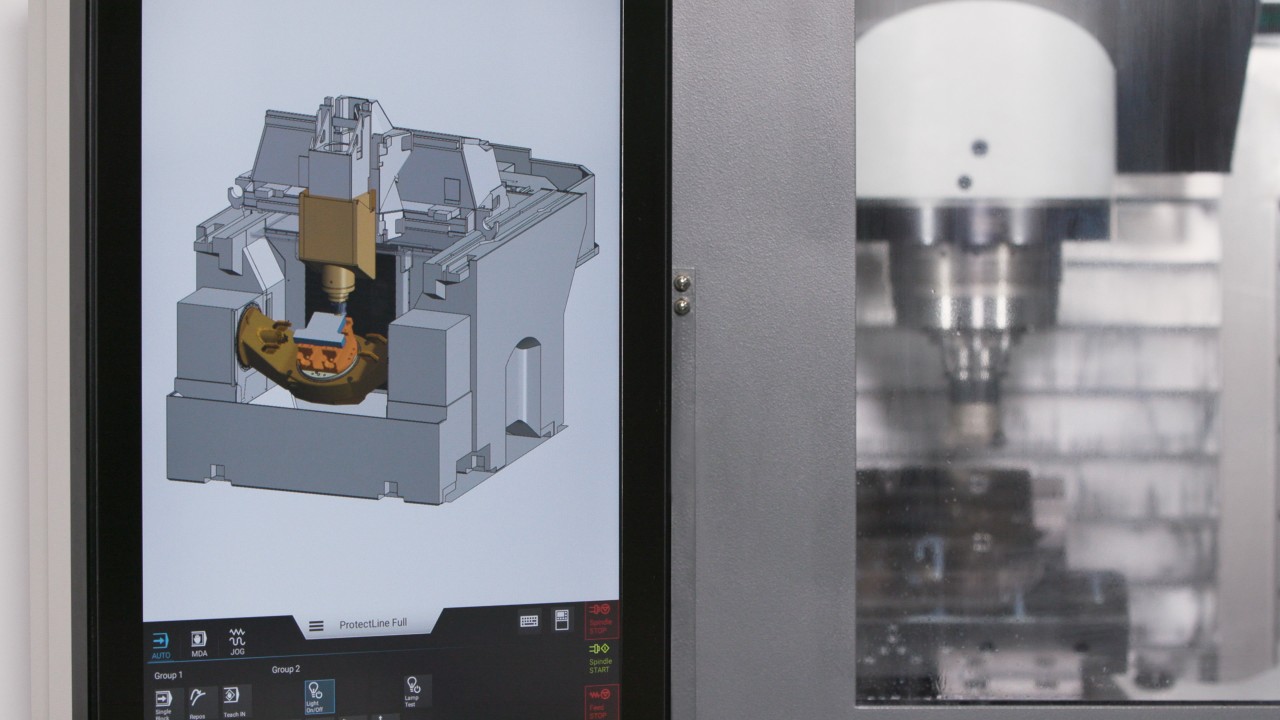

Coating, 3D printing or

repair

Automatic changing of

application heads

Weld filler metals as

wire or power

Working on three, four

or five axes

Programming in DIN ISO

or CAM

Easy to use with the

SmartLine Module TouchLine

Always at top speed

To transfer these varied

requirements into practical solutions, it isn’t just Fouad Cheaitani and Axel

Boi who are constantly in discussion. In Dottikon and Tuttlingen, teams from

all departments work closely and constructively together. Every two weeks there

is a team meeting, where all the application engineers, material specialists

and software engineers get together and to discuss issues and progress. Every

department contributes different expertise and view points, which are

discussed, and then discarded or implemented as quickly as possible.

The worry that the CHIRON

Group was too large to move at this pace quickly dissolved. The Additive

Manufacturing division has, according to Axel Boi, »A start-up character – very

dynamic and flexible. On the other hand, we have access to CHIRON Group reserve

resources and support, and more experts that we can call upon if necessary.«

Stellba’s focus is new materials and possibilities

Fouad Cheaitani is on the

»side of material«. One of the reasons why Stellba decided to collaborate with

Axel Boi’s team was, »many companies got involved on the software side or the

technology side – but for the perfect results and more applications, the

material had to be perfect. As a distinguished materials expert, Dr. Nasim Bosh

is the ideal sparring partner for us.« Eventually, in the future, Stellba

doesn’t just want to build components with the existing material range of wire

or powder, it also wants to develop new specially adjusted materials and

coating materials for Additive Manufacturing. They should help achieve the

required mechanical values and realize new material properties – for example

with new additives or new compositions.

Will this work better with

wire or powder? On the one hand, this is a matter of experience, on the other,

a case of experimenting. Of course it will take time, but in comparison to

developing and gaining approval for completely new materials, the desired

results are found much more quickly. Not least thanks to the idea-ping-pong

going on between them and Axel Boi’s team, where ideas and approaches are

communicated openly, and jointly tested and fleshed-out for feasibility.

Easy to use: a real USP

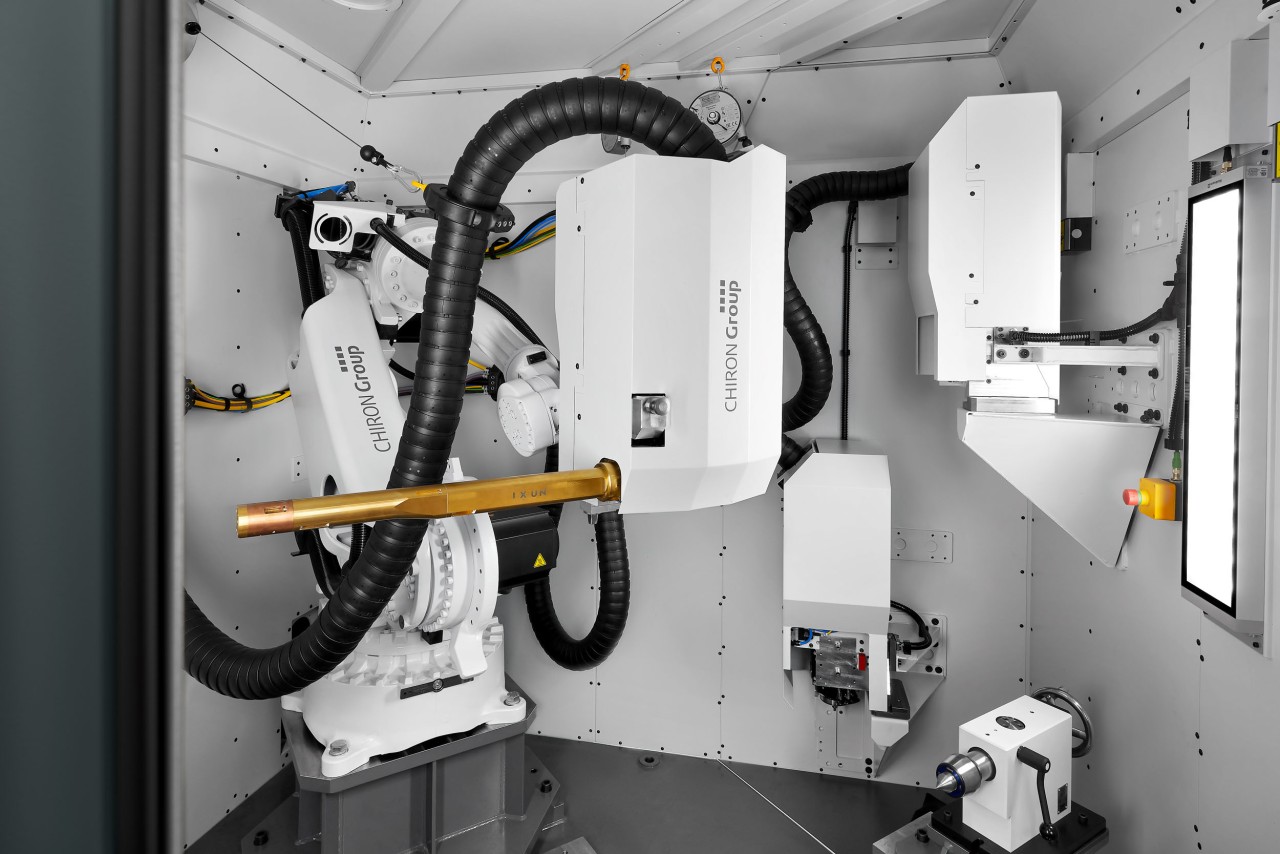

And now, back to reality,

after a brief foray into the future of Additive Manufacturing. The important

thing is the safe mastery of these highly complex technologies to minimize

operating errors. According to Fouad Cheaitani, one of the central benefits of

the AM Cube is »automatic changing of the application heads. Whether wire or

powder, 3D printing or coating, internal or external... Things that take hours

for other manufacturers take only minutes here, and without the need for manual

interference. It’s unrivaled.« Equally unrivaled – and incidentally a small but

positive surprise for Axel Boi too – is that the AM Cube takes just five days

to install and set up.

One of the three AM Cube application heads for applying powder using a lance for the interior coating of components. The three different application heads allow the application material – wire or powder – to be changed in various phases of production.

»The automatic changing of the application heads is a key advantage of the AM Cube, and a true USP. It’s unrivaled.«

Fouad Cheaitani

Head of Sales, Customer Support and Business Development at Stellba

Variety as a goal – check.

Coating, 3D printing or

repair – It’s all possible with the AM Cube. And the various applications at

Stellba prove that anything is possible. Since it was commissioned, various

research projects have been run on the 3D metal printer in collaboration with

prestigious Swiss universities and, since December, it has taken on even more

different orders. It has been welding half-shells for brakes in locomotives,

coating the inside of components with aluminum-bronze and repairing turbine

blades.

Currently, they are

building an impeller for a turbine fully additively. Stellba also carries out

repairs on various components using the AM Cube and is working hard on

qualifying new materials such as tungsten carbide or materials based on nickel.

Welding test with aluminum-bronze to calculate the process parameters – magnetic brakes for locomotives

Cable guide with anti-wear coating made from Stellite® 6

Kneading cogs coated in tungsten carbide

The development

partnership is a resounding success, not just in finding more options for all

AM Cube users, says Fouad Cheaitani, »to our delight, and that of our owner and

CEO Philipp Jutzi, the system is already making us money.«

The trial phase is

now complete and the AM Cube has already mastered a huge variety of industrial

tasks at Stellba, with flying colors.

This begs the question,

will Additive Manufacturing replace existing technologies? Fouad Cheaitani and

Axel Boi are united in thinking that it won’t. But the engineers have more

possibilities when developing components, both regarding the lower weight of

the part and saving energy, and the design.

Click

here to find out more about the highlights of the

AM Cube, applications and options.

Interested in more

information or a personal discussion about the AM Cube and its industrial uses

at Stellba?

Axel Boi welcomes your request and would be

happy to put you in contact with Fouad Cheaitani.

Stellba AG

Stellba AG was founded

in 1957 and has its headquarters in Dottikon, Switzerland, with a large-scale

production center in Baden. Today, it is one of the most in-demand global

specialists on tailored customer coating and machining solutions which protect

products and components from erosion, abrasion, corrosion and oxidation,

thermal loads or combinations of various types of wear. The applications for

the high-tech finishings include hydro-power plants, thermal power plants,

pumps and compressors, components in high-temperature zones and thermal barrier

coatings (TBC). Stellba is a contract manufacturer and a partner in the energy

supply, oil and gas, maritime, and printing industries, as well as the

chemical-pharmaceutical industry. It develops innovative processes in its

in-house material laboratory and is a leader in future-focused technologies

like laser deposition welding and additive metal machining.