High-speed

manufacturing with machining centers from the CHIRON Group, Renishaw technology for

machine calibration and optimization, process control, and automation: Visitors

to the event could experience live the perfect fit between the portfolios of

two leading providers in their field – at the first RENISHAW & CHIRON DAYS

hosted by the Hungarian branch of Renishaw in Budaörs, near Budapest. The

three-day event was organized by Attila Gál and Dénes Papp, Managing Director

of ROLATAST Kft., a sales and service partner of the CHIRON Group. According to

Dénes Papp, the Hungarian units have worked »together successfully

for many years, and digital measurement systems from Renishaw are used in

around 90 percent of the machines we offer.«

Renishaw,

a leading provider of high precision metrology and healthcare technology based

near Bristol in the UK, presented different calibration products. In live

demonstrations, visitors could see how sensors perform workpiece and tool

measurements as well as tool breakage monitoring. In addition, Renishaw

showcased an EQUATOR 300 gage for high precision measurements during the

production process, and a REVO 5-axis measurement system. It allows a full

workpiece inspection to be carried out – including a surface finish analysis –

with measurement precision down to the micrometer.

Two sides of one machine:

Something new out of something old

One

exhibit shown by CHIRON Group was a retrofitted machining center, the CHIRON FZ

12 W. It looked as though it had been cut in half and put back together again. »We wanted to show the

impressive effect of a retrofit by our specialists at CMS – both visually and

in terms of the productivity and future viability of a machining center. So we

left the right-hand side in its original state and completely refurbished the

left side,« says Zsolt Richter, Technical and Sales Support Manager at

ROLATAST.

Photo: cnc.hu

Special

feature of the »new« FZ 12 W: The original Siemens SINUMERIK 810

controller was retained and the latest model, the SINUMERIK 840D sl, was added

to it. This measure alone reduced the cycle time by 20 to 25 percent.

»For a lot of our customers, a retrofit is a good way of updating their production quickly while keeping costs manageable.«

Zsolt Richter

Technical and Sales Support Manager at ROLATAST

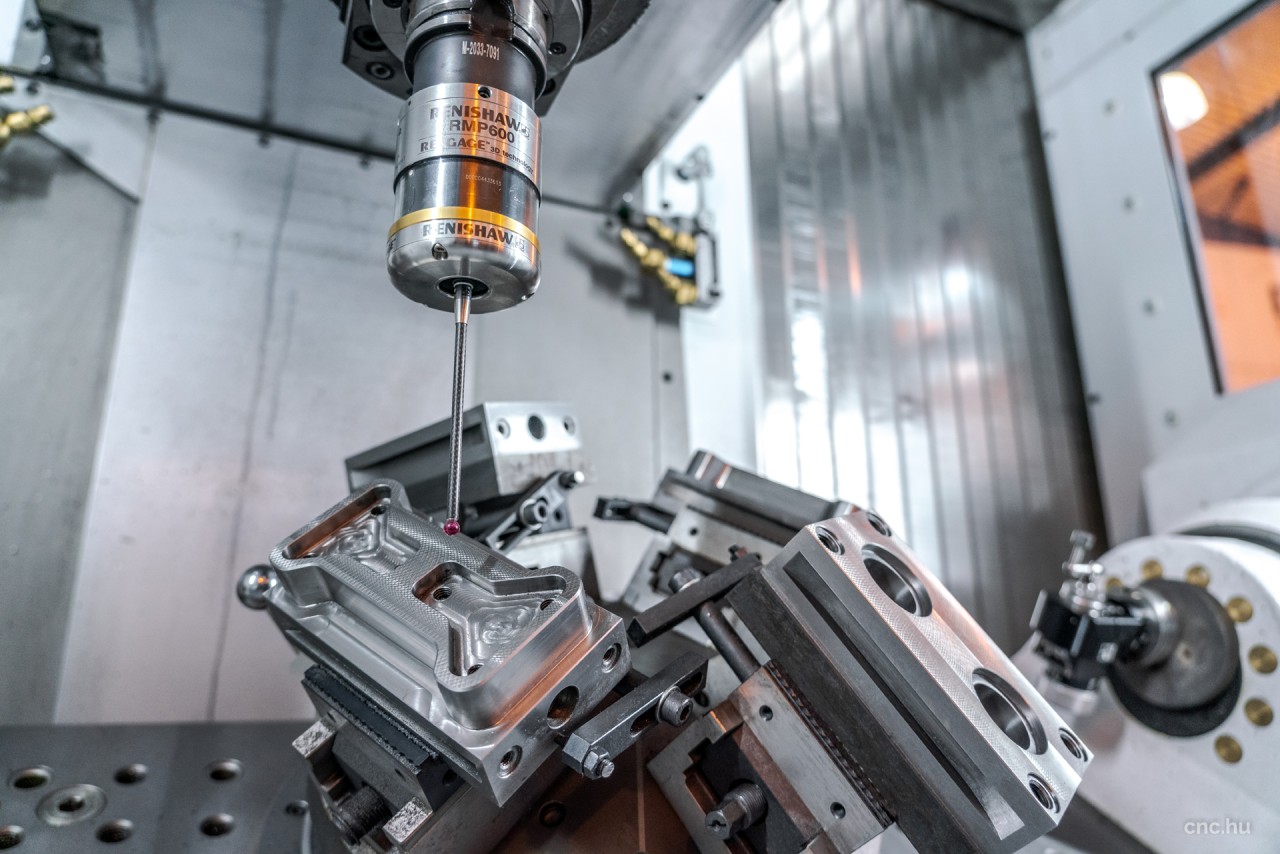

Another

exhibit at the three-day event was a CHIRON FZ 15 S five axis with multiple

clamping on the fifth axis, which enables incredible precision while maximizing

productivity. The Renishaw RMP 600 RENGAGE high-accuracy probe was used for

support.

In

addition, customers could visit the CHIRON Group virtual showroom to find out

about the different brands of machining centers and areas of expertise in the

various fields of application. With just a few clicks, they could find »their« system, inspect it

closely using 3D models and animations, and view examples of it in use.

»There is no doubt that we have strengthened both our partnership and our customer relationships thanks to the event.«

Attila Gál

Sales Director at Renishaw Hungary Kft.

Review : Take a look back