A customer survey carried out last year

confirmed, that the pre-configured machines in the baseline Series are in high

demand and, especially in the contract manufacturing sector, customers wanted

more models. Whether being used in the aerospace, automotive sectors,

mechanical engineering, medical technology, precision technology or tool

manufacturing, the situation regarding orders is noticeably improving, often up

to or beyond the capacity of the firm. And that’s precisely where the models

come into their own, with short supply times, an attractive price and proven,

state-of-the-art technology

Pre-programmed for success –

the advantages of baseline:

Available quickly, durable and low-maintenance

Vertical moving column principle

High rigidity and thermal stability

Maximum precision in positioning and simultaneous operation

Dynamic direct drives and precision guides

Ergonomic operating and loading concept

Easy access to all units for servicing

Low-maintenance and with a long service life

DataLine can be integrated for

machining and prognosis data

Three strong new contenders

A

new entry from the 08 Series is the FZ 08 S five axis baseline, one of the most

versatile machining centers in the compact class. It’s quick to set-up, easy to

operate, very stable and highly dynamic when machining. There are also two

additional models from the MILL Series. The MILL 2000 baseline, with a 2,000 mm

travel path along the X-axis, is ideal for machining larger components or

multiple clamping positions. With its swivel head, the MILL 2000 baseline

offers increased freedom and a range of application possibilities. In

combination with a round-table package, it can be used for five-axis machining

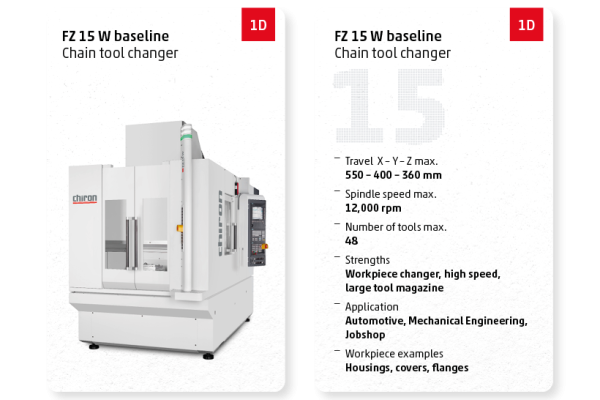

of large workpieces. As well as the three new models, the FZ 15 W baseline is

now available with both a basket and chain magazine.

baseline »to go« – in the CNC

Outlet Center

Since

October 2020, the CHIRON Group has also had a hub in the CNC Outlet Center in

Olching, Germany. The hub is just a three-minute drive from the A8 highway –

exit 78 towards Dachau-Fürstenfeldbruck. Here, you can browse a range of

machines including the FZ 15 W baseline. The demo-machine is available

immediately, in top condition, and ready to operate

within two to three weeks. The complete range of currently available

machines can also be seen online, on the exhibitor website.

For

Matthias Rapp, Head of Area Sales for Germany, Austria and Switzerland at the

CHIRON Group, the Outlet Center is »a new and interesting sales channel and a

fantastic opportunity to reach a wider audience of potential customers with the

baseline Series for classic machining.« As well as exhibiting the machines, the Outlet Center plans to hold lectures and machining seminars, although all events are still on-hold due to COVID-19.

More orders than machine

capacity?

You can find

information on all machine types in our new brochure »CHIRON baseline – Proven

top technologies available at short

notice«. You can also get in touch with Matthias Rapp to discuss your

requirements and orders via phone or email.

Matthias

Rapp

Head

of Area Sales for Germany, Austria and Switzerland at the CHIRON Group

Tel. +49 7461 940-3181

[email protected]