The more productive a machining center is in

manufacturing components, the more economically and thus sustainably the

resources of space, energy and raw materials can be used. That much is clear,

at least in theory. But what does that mean in practice? When is a machine

particularly productive?

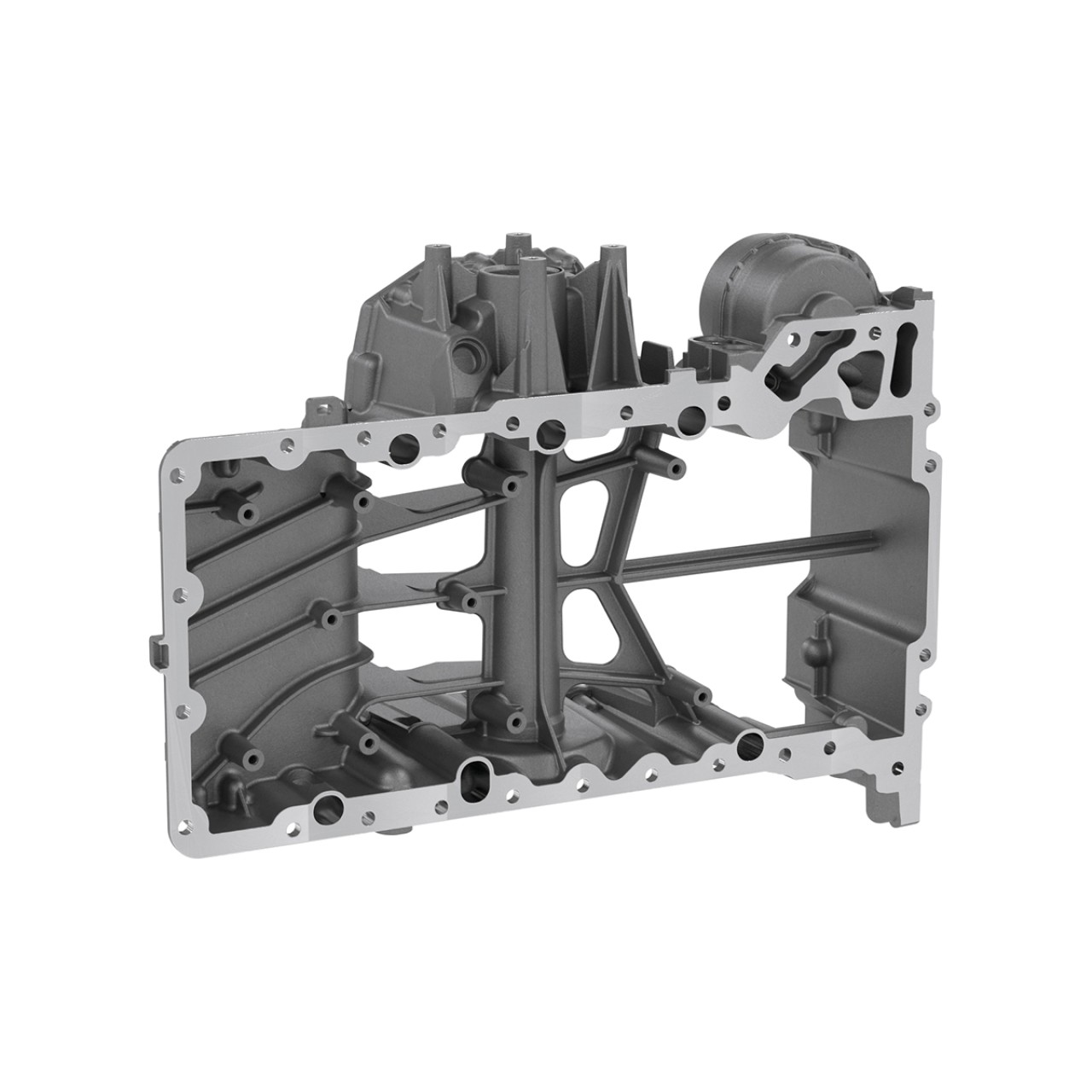

When the cycle times are significantly shorter,

for example. The 16 Series operates approximately 20 percent faster than the

predecessor series. A customer needs fewer machines, less space and fewer

peripheral devices - for example for a coolant supply - for the same output.

Production is more efficient, and therefore more sustainable, if multi-spindle

systems are used instead of single-spindle devices: »Our stated objective

is for a double-spindle machine such as the DZ 16 W or the STAMA MT 733 to

produce two workpieces in the same time that a single-spindle machine needs for

one workpiece – of course with the same high quality standard. The reduced

requirements for space, energy and investment costs compared to single-spindle

machines are very attractive for our customers,« says Dr. Claus Eppler,

CTO at the CHIRON Group.

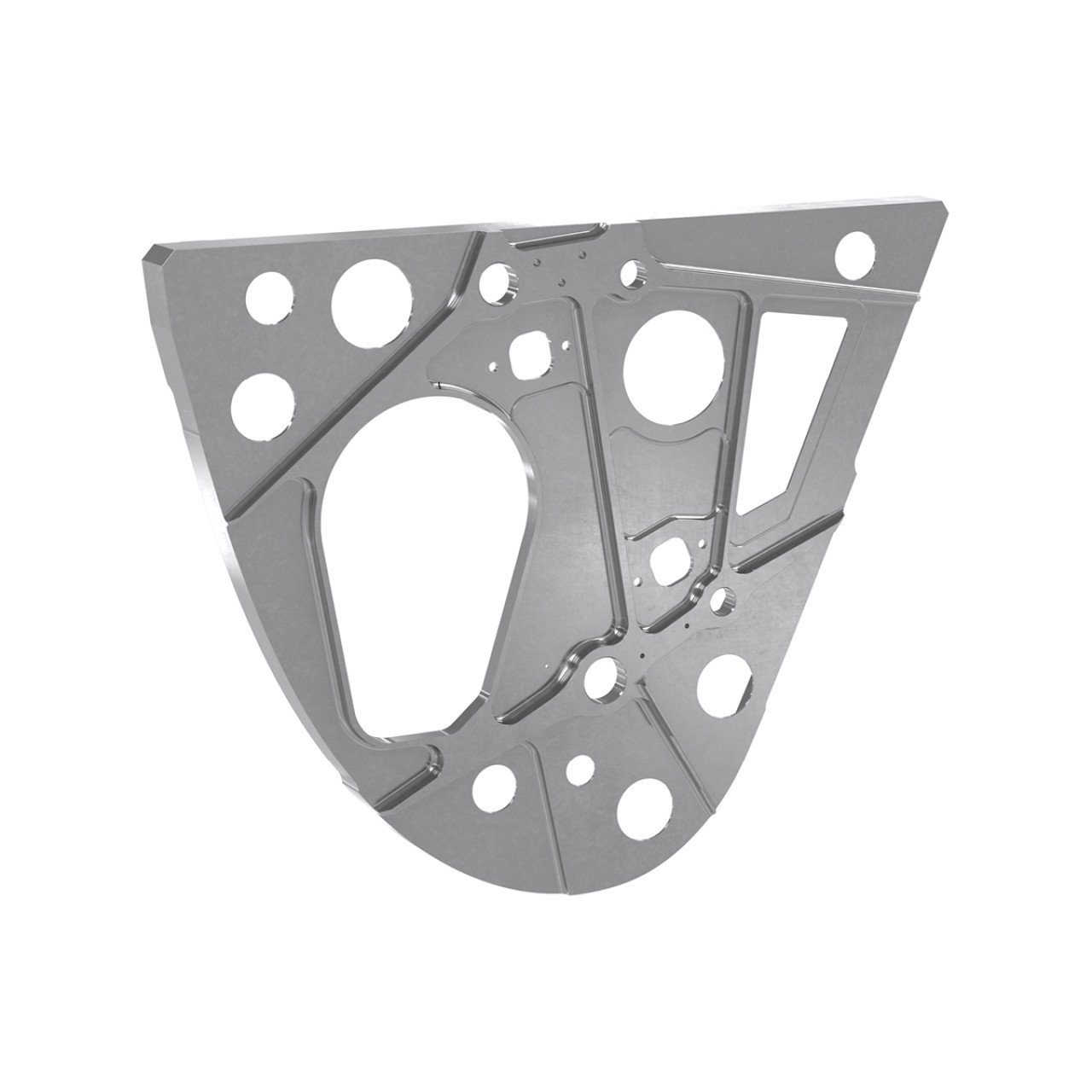

Automatic

tool changes, workpiece changeover via a pallet changer or a tool change unit

as well as loading and unloading the magazine in parallel contribute to the

short cycle times which can be implemented for example with the CHIRON 16, 22, 25 and 28 Series and with the STAMA MT 733. Sustainability is also reflected in a variety

of other technical solutions which add up to considerably more energy

efficiency.

Technical

solutions for greater energy efficiency

Continuous use of frequency-controlled drives

or IE3 motors

Standard feed-back of the servomotors' brake

energy

Hydraulic units in storage-charge operation

Consistent mass optimization of all mobile

components in the machining center

Milling spindles with energy-efficient

synchronous and asynchronous motors to reduce the magnetic flux during turndown

Optional machine recooling in place of the

customer's chilled water distribution

Powersafe function for needs-based switch-over in stand-by-mode

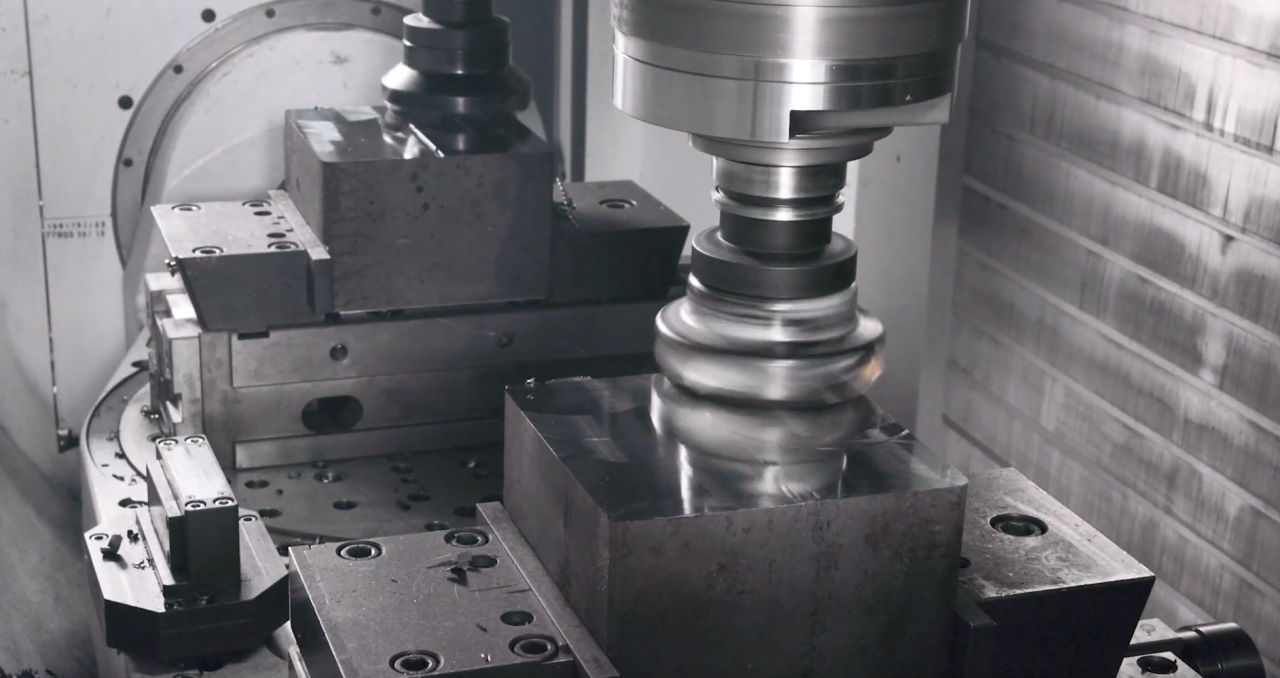

Automated

machining opens up further potential

»The

constantly increasing use of automation solutions is an important trend in

manufacturing,« states Dr. Eppler. »Ideally, several machines are

operated by one employee, in the best case scenario in just one or maximum two

of three production shifts. The night shift - unpopular with the staff and

expensive for the company - should run on its own, in a manner of

speaking.« This can be achieved with an automation solution like the

VariocellUno. Digital monitoring and messaging functions make it possible to

have disruption-free, highly efficient production even in autonomous operation.

The combination of the CHIRON DZ 16 W and the compact automation unit VariocellUno facilitates a particularly productive exchange of unfinished and finished part pallets during machine operation in series production and allows the manufacture of several workpieces during very short cycle times.

Digital

assistance saves resources – across the board

Thanks

to the digital systems of the SmartLine portfolio and SmartServices, the CHIRON

Group provides the best support throughout running operation and ensures

additional efficiency, availability and productivity of the machining centers.

And as for saving resources cross the board: servicing procedures at one site

can be combined and scheduled for a single date. Disruptions can be rectified

from afar thanks to remote support, thus avoiding travel – along with the

associated CO2 emissions. The running-in times and commissioning of

the actual machining centers are also decreased due to virtual machine

commissioning and simulation of customer processes.

Repair instead of

replace – thanks to the AM Cube

The AM Cube, the first 3D metal printer of the

CHIRON Group, has so many good features, as Axel Boi explains in the following video clip.

One of these positive features is

sustainability: larger components can be assembled directly and precisely in

the customer's production line without the otherwise high material costs,

without long procurement times and environmentally harmful transport. Components

are protected from corrosion and wear if they are coated using laser deposition

welding procedures, they last longer and release fewer harmful substances - for

example, abrasion from brake disks - into the environment. In addition, the AM

Cube is ideally suited for repairing parts – another advantage in view of

sustainability with manufacturing solutions of the CHIRON Group.

Dr. Nicole Hoffmeister-Kraut, Minister for

Housing, Work and Planning for the Federal State of Baden-Wuerttemberg, was extremely

interested in sustainable manufacturing solutions and retrofits for longer

machine service life during her visit at the CHIRON Group. The minister was a guest in

Tuttlingen at the end of July as part of her transformation trip.

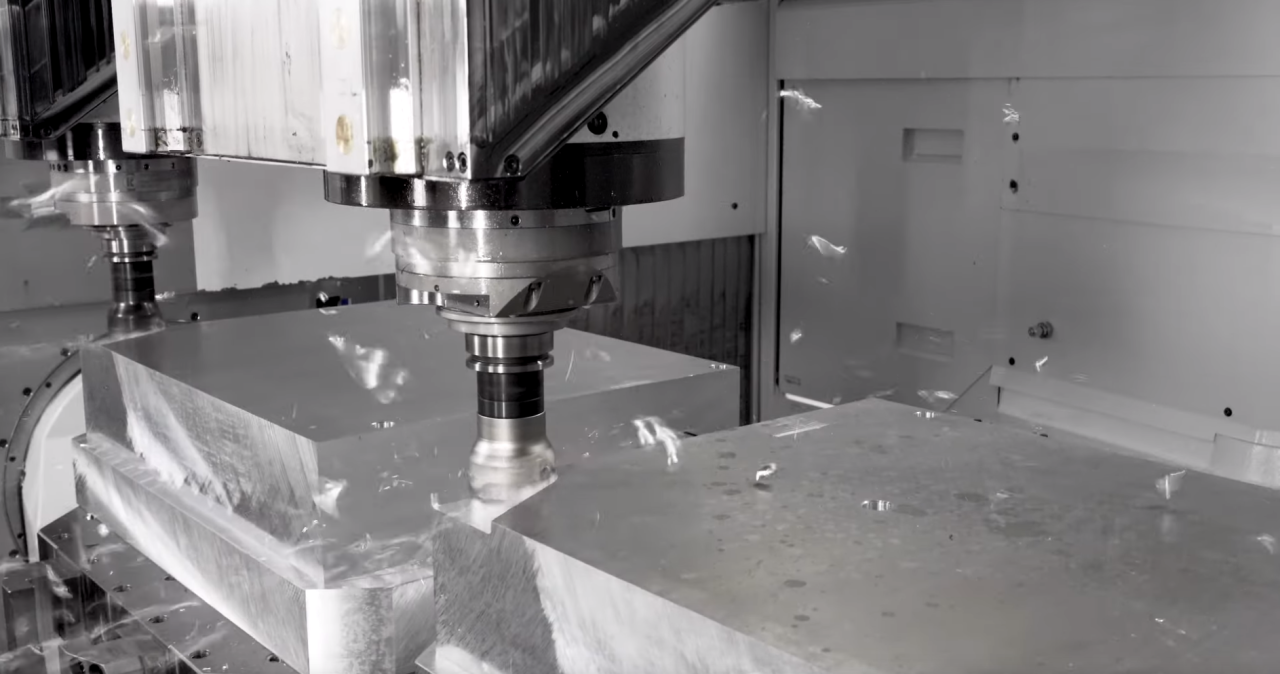

Preserving

values, saving raw materials: retrofit instead of new purchase

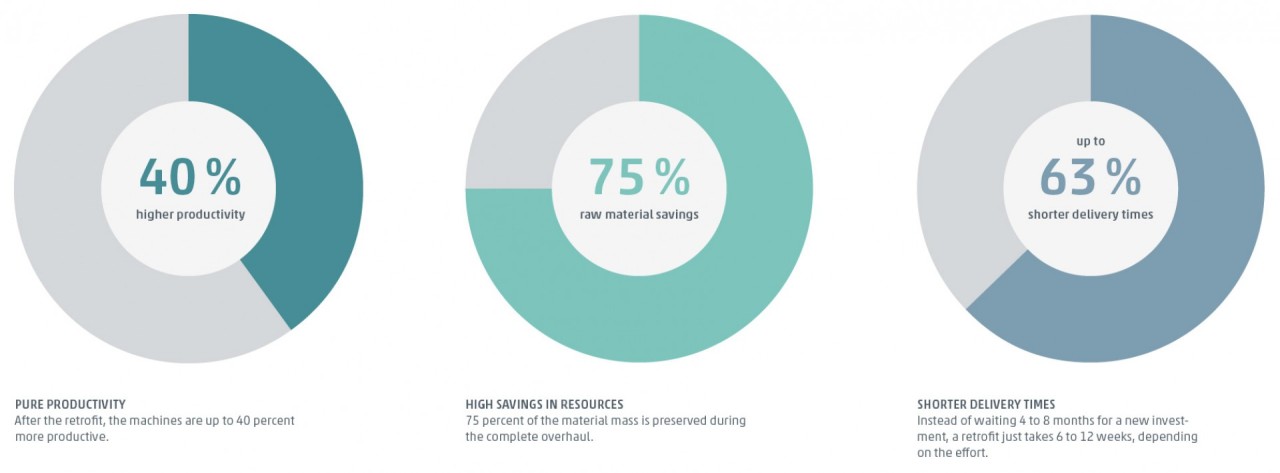

Sustainability also means preserving values. A

machining center from CHIRON or STAMA brand represents such a value, even if it has

been in operation for many years.

An »aging« machining center has had new life breathed into it by the CMS specialists, ready for a new, more productive and more energy-efficient machine life.

The life cycle of existing machines can be

increased with a retrofit solution from CMS – and not only that: all important

elements such as drives, main spindles and control are reconditioned, which

means the systems manufacture 30 to 40 percent faster than before. At the same

time, the energy requirements decrease: the thermal energy from the cooling

circuits can be fed into the customer's central water circuit, special drive

motors feed any energy that has been generated but is not required back into

the mains supply. The greatest potential for savings provided by a retrofit is

with the raw materials at 75 percent, compared to a new purchase. The most

important factor for the customers - along with the lower investment costs - is

the delivery time: already modernized machining centers from the CMS portfolio

are available in just two weeks, a customized refurbishment is completed in six

to 12 weeks.