Zurich,

Biel, Geneva, La Chaux-de-Fonds: The micro on tour will be stopping in these

cities, where the truck will be transformed into a two-story showroom with

video and product presentations, offering space for presentations on innovative

solutions and face-to-face meetings. Seven partners are on board in addition to

the CHIRON and FACTORY5 brands. The companies all interact perfectly right

along the precision manufacture process chain, just like the components of a

Swiss clock.

Want

to find out more?

Click

here for the German and French registration pages for micro on

tour.

Formnext, METAV,

Intec/Z: Digital versions still highly successful

Event organizers in Frankfurt and Leipzig opted for digital

formats, which were very well received: In November 2020, around 9,000

participants from over 100 countries joined Formnext Connect, learning all

about additive manufacturing, the next generation of industrial production.

Examples of new products included the 3D printer AM Cube and, in an exclusive

preview, the latest additive manufacturing project at the CHIRON Group: AM Coating,

an innovative solution for coating brake disks.

The Leipzig

trade fair duo Intec/Z also took place in a purely virtual format on March 2

and 3, 2021. More than 2,000 registered visitors took the opportunity to learn

about new developments in the metalworking and supply industry at Intec/Z

connect. The participants spent four hours on average on the platform, watched

keynote speeches in the »Trends in

Manufacturing Technology and the Supply Industry« or »Additive +

Hybrid – Manufacturing in Transition« forums, and

gained interactive insights into current trends through more than 100 exhibitor

presentations. Frank

Scheibe and Marcus Hansberg from the CHIRON Group sales force were on hand live

from Leipzig and were pleasantly surprised: »The response was fantastic; we were in chats and video

conferences almost non-stop, and the quality of contacts was excellent too«, enthuses Frank Scheibe, Technical Sales/Field

Service at the CHIRON Group.

»Networking three in one« was the slogan of METAV digital

2021, which took place from March 23 to 26, 2021. With a virtual exhibition,

matchmaking, and web sessions, the online trade fair was »very well attended and accessible

from anywhere in the world 24/7,« explains Stephanie Simon, VDW Project Officer

in charge of METAV digital. As with a live event, the visitors could navigate

through two halls and stop to have a closer look at, for example, the CHIRON

Group booth, where the CHIRON DZ 25 P five

axis double-spindle machining center for processing large, complex workpieces was on show, among other exhibits.

Livestream

from Tuttlingen: 11th Colloquium on Medical Devices

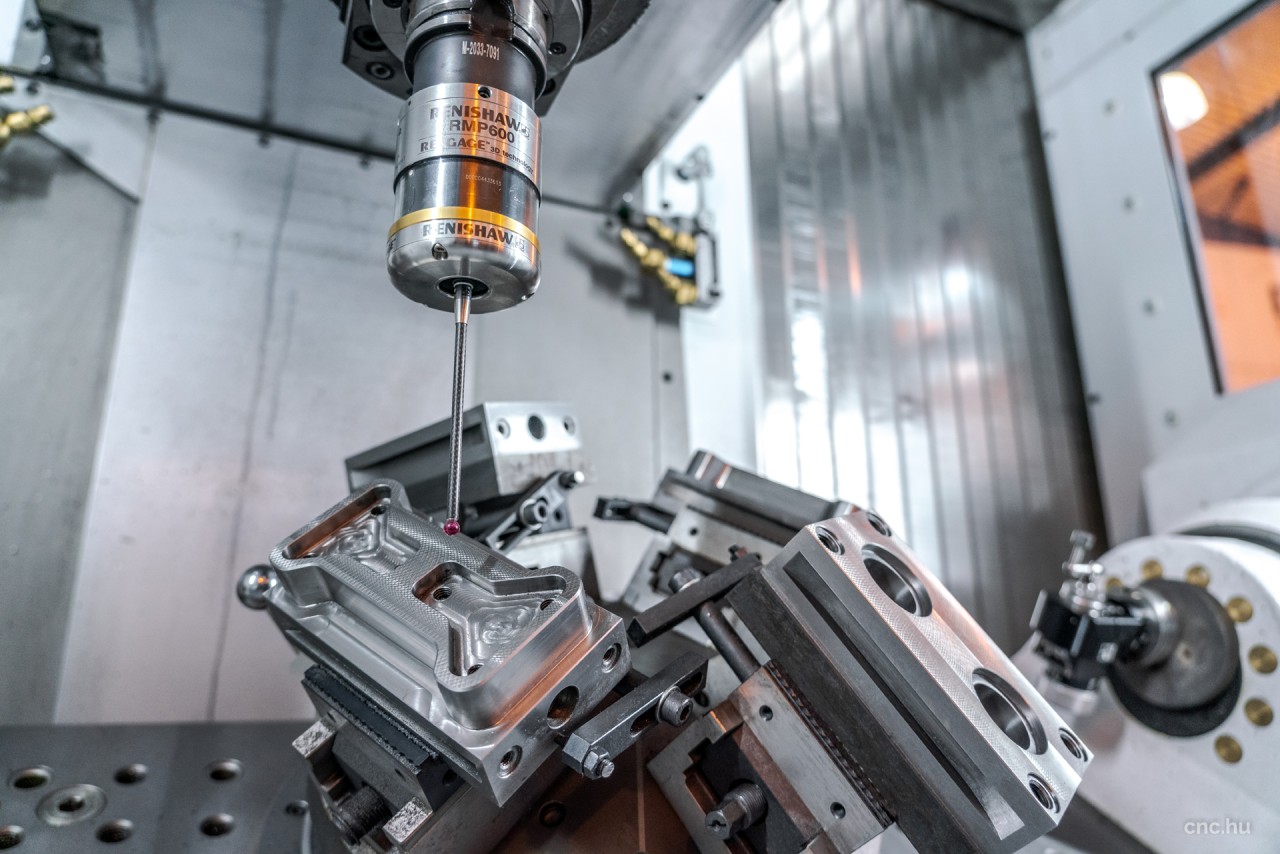

COVID-19 has highlighted the crucial importance of medical engineering,

and how essential it is to ensure products are manufactured under consistently

optimum conditions, using highly secure, reproducible processes. Just as

important is the perfect harmonization of metal cutting technologies and tools,

so that extremely hard materials can be machined precisely and productively.

What form does this harmonization take? That was one of the questions discussed

in presentations and podium discussions at the 11th Colloquium on Medical

Devices of the mav. The topic introduced by Samuel Vuadens, Managing Director of CHIRON

Swiss and the FACTORY5 brand, was »High-Speed

Machining of Medical Microtechnology Parts using the Micro5 Smartmachine.« Andreas

Jenter, VHM Milling Tool Product Manager at Horn, discussed optimized milling

processes with standard and special milling tools in his keynote speech. Ralph

Hufschmied, Managing Director of Hufschmied, spoke about high-efficiency

machining of complex materials. The live-streamed event closed with a virtual

visit to the CHIRON Group's Medical & Precision Technology Center.

You

can catch up on recordings of the podium discussions and presentations at:

https://mav.industrie.de/medizintechnisches-kolloquium-2020/

International Sales &

Service Meeting (ISSM)

Usually,

sales staff from all over the world come to Tuttlingen, Germany, for a few days

every spring to find out all about new products, discuss their markets and the

current challenges, and to gain inspiration for success at their sites from

presentations. This year, the ISSM was broadcast live from the studio in

Tuttlingen in two sessions per day, and was simultaneously interpreted into numerous

languages. Interactive presentations, Q&A sessions, and a virtual

get-together in the coffee bar – with stickers sent out in advance for the very

varied cups – allowed the participants to almost forget that they could only

see each other and discuss matters on screen.