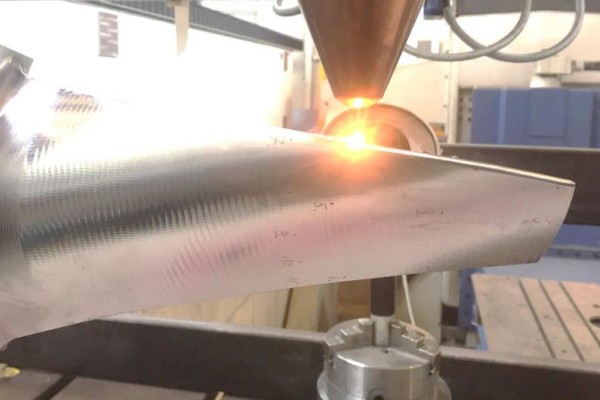

Housings for electric motors and transmissions, oil sumps,

chassis components: Just like for large high-precision mechanical products,

such as cooling elements or distributor housings, the following used to be

true: High precision takes time. And high dynamics come at the expense of

precision. The new CHIRON series 22 tackles this contradiction convincingly.

The basis for the innovative machine concept with small

footprint of around 25 m2 is – like series 16 – a machine platform

in a moving gantry design. The rigid machine bed and active component cooling

enable the required degree of precision on the workpiece. High axis

acceleration and fast rapid traverses ensure dynamic machining as never before seen with

workpiece dimensions of this size.

In addition to precision and dynamics, series 22 also

offers impressive flexibility. From very complex workpieces or product series

with many different tools: The magazines offer space for up to 77 pieces and,

thanks to the integrated workpiece changer, the workpieces are loaded and

unloaded during machining operation and therefore extremely productively.

Two spindles –

one fast, one strong

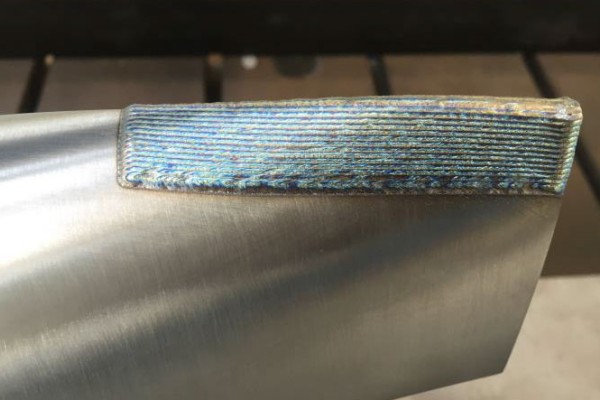

Depending on the processing task, two different main

spindles are used in series 22: One fast spindle with a speed of up to 20,000

rpm and a torque of up to 110 Nm for workpieces made of aluminum or aluminum

alloys. And a strong spindle with a speed of up to 12,500 rpm and a maximum

torque of 200 Nm for hard materials and large tools.

Impressive on

all counts

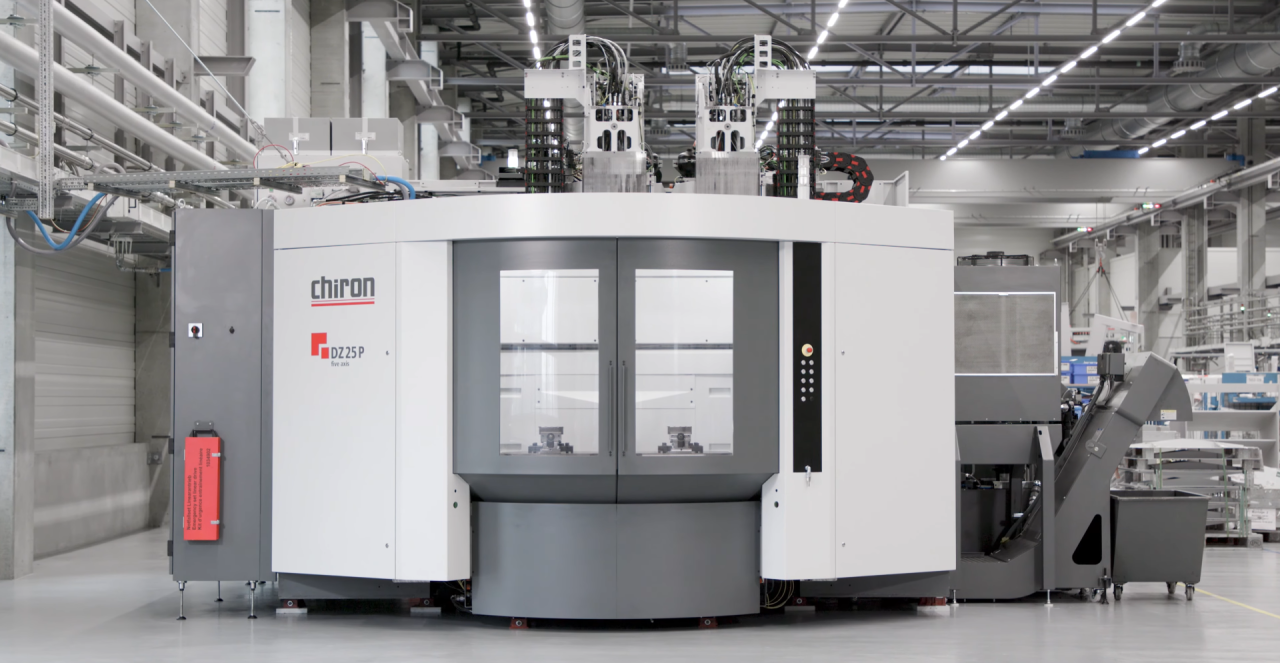

The working areas is easily accessible, and the process

easy to see thanks to the large glazed doors. The control panel is located

directly next to the working area, making set-up easier. The new machines are

operated easily and according to context via the TouchLine operating system.

On the back, the tools are inserted in the chain magazine,

and the tool data can be entered here directly via the operating console.

Tool replacement is carried out during machine operation;

the new tool is clicked into the magazine with a single movement of the hand.

Modular design

for application-oriented configuration

Series 22 is available with two drives: A ball screw drive

or a linear direct drive. You can also choose from two plate variants: A

suspension plate for four-axis machining or two face plates for five-axis

simultaneous machining. All

models can also be supplemented according to the application – e.g. with

a cooling system, suction unit, chip conveyor, individual tool packages. To

increase the degree of use, the specialists at CHIRON develop individual

automation solutions together with the customer.

Even better

with SmartLine

To tap the full potential of digitalized production, series

22 is prepared for the integration of various SmartLine modules – for a clear

plus in terms of productivity, product quality and machine availability.

ConditionLine: Early detection of

non-typical operating behavior and targeted planning of maintenance and repair

ProcessLine and

ProtectLine:Reliable protection against machine crashes with a digital twin, both in

preparation and during running operation

Presentation at

the OPEN HOUSE ONLINE

The new series celebrates its premiere

in May in a new way - at the OPEN HOUSE ONLINE. Here, CHIRON will inform you

about the highlights of the DZ 22 W five axis and demonstrate the machining

centre live under cutting.

You want to know more about the precise

and dynamic machining of large components in advance?

Kristoffer

Siegmann, Head of Global Account Management

Automotive is looking forward to

your call or e-mail.

Kristoffer

Siegmann

Tel. +49 7461

940-3074

[email protected]