AM for

additive manufacturing, Cube for the shape: This is how the first 3D printer from

the CHIRON Group got its name. According to the objective of the development,

the AM Cube should be very versatile: It can be used to produce semi-finished

products, repair components or apply coatings. It should also be "easy to

use" and be used predominantly in mechanical engineering, tool

manufacturing, energy production and aerospace.

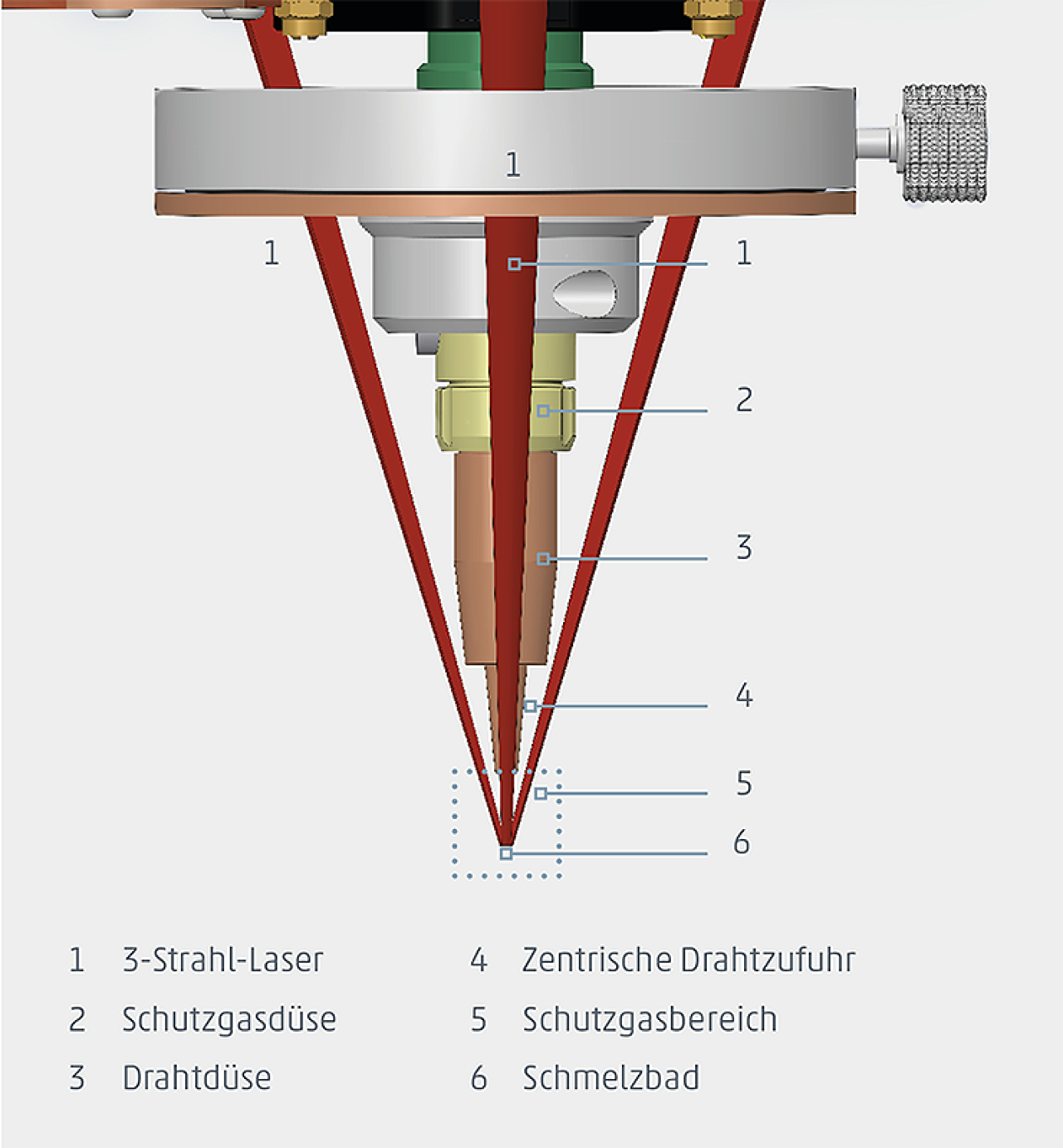

This

is exactly where the particular challenge for the CHIRON Group's Additive

Manufacturing team lay. They had to design a practical solution for the

industrial use of laser deposition welding, which would meet the

customers' high requirements. But there is currently no magic formula for

either the best possible process or the ideal materials – such as the quality

of the powder or the properties of the welding wires. A further focus was the

safety-technical equipment of the system. The required expertise to develop a

convincing solution from the still young technology, was and is being

significantly built up and further developed by the CHIRON Group.

Modular platform

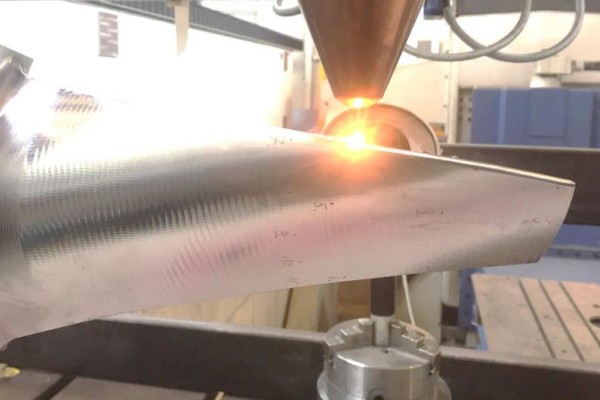

To

ensure that customers can use the AM Cube in a variety of ways, the team

working for Axel Boi, Head of Additive Manufacturing, developed a platform: A

five-axis system for the construction, coating and repair of cubic components

and a four-axis system for shaft processing. All core components are fitted to

the base with a modular design and are housed in a laser-proof and gas-tight

cab. Peripherals such as the laser source, wire feeder, cooling system and

control cabinet are positioned outside. The modular design allows for

adaptation to specific customer requirements and also further variants in

future too, such as with automation solutions.

AM Cube put to the test

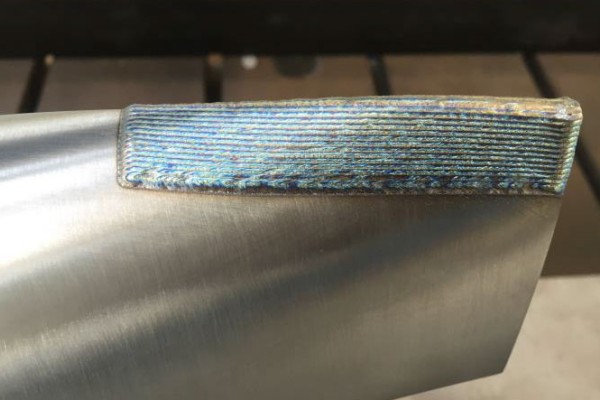

With

the Swiss company Stellba AG, the CHIRON Group was able to win a pilot customer

that couldn't be more suitable: Stellba repairs and coats components of water,

steam and gas turbines and has a lot of experience in the fields of coating,

additive metal processing and laser welding, so it's the perfect customer to

put the AM Cube through its paces under real production conditions.

… and at the OPEN HOUSE ONLINE

Who would like to know

more: Axel Boi is gladly available for a consultation. On request also in

direct user dialogue with Fouad Cheaitani, Customer Support and Business

Development at Stellba. Axel Boi also presents the AM Cube outside the OPEN

HOUSE ONLINE on site in Tuttlingen. As soon as circumstances permit, we look forward to a personal meeting. Please contact us to arrange an appointment.

Axel Boi, Head of

Additive Manufacturing

Tel. +49 7461

940-3871

[email protected]

Axel Boi (left) and Fouad Cheaitani (right) from Stellba are looking

forward to the professional dialogue with you.