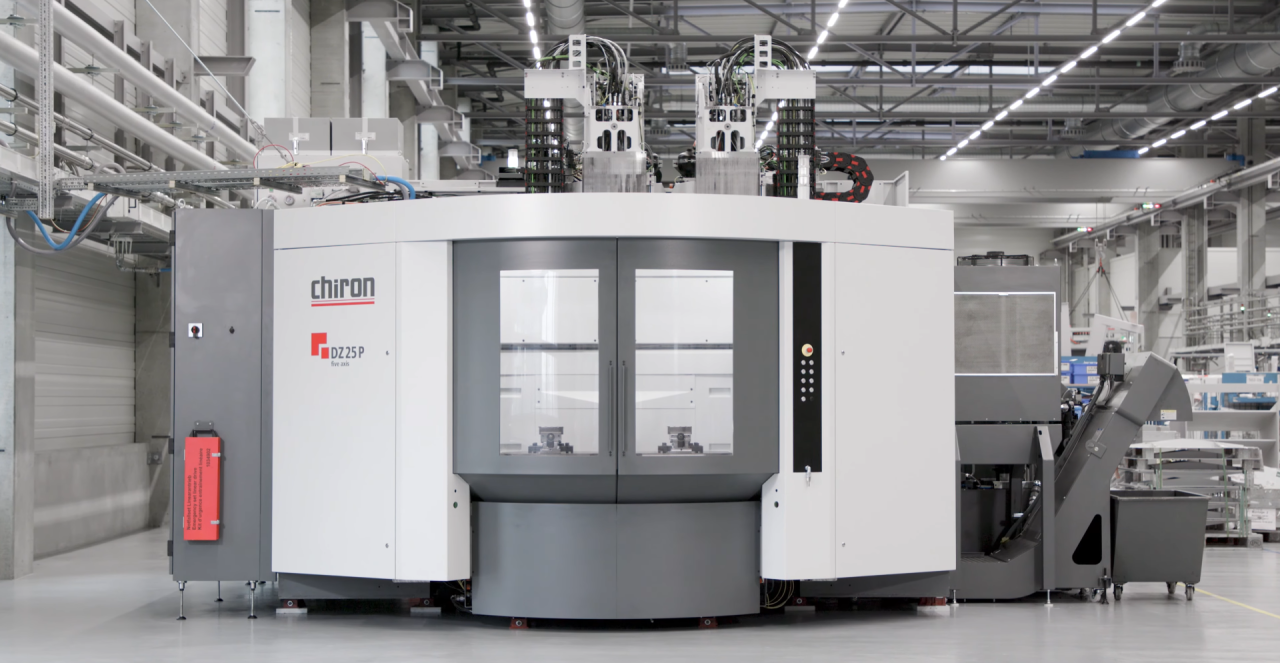

FZ/DZ 25: The new standard for large components

The new CHIRON 25 series is designed to be compatible with the high-productivity machining of complex, large-volume structural components for the automotive industry and aviation. The entire process is easily accessible and completely viewable – a novel feature for workpieces of these dimensions.