The minister continued: »That's because

this factory combines the very best that our machine tool industry in Baden-Württemberg

has to offer: Machines which combine the highest productivity with the highest

precision and thereby set standards for the digital age.«

Unique factory

for unique machines

Since August 2019, the CHIRON Precision

Factory, the biggest single investment in the company's history at EUR 34.5

million, has been offering the best and, above all, very stable framework

conditions for the construction of up to 400 machining centers per year.

Currently, CHIRON's tried-and-tested series 15 and 18 as well as the two new

series 16 and 25 are being produced in Neuhausen ob Eck. Assembly of series

22 will begin soon. This new series is ideally suited to the precise,

dynamic machining of large components in the automotive and precision mechanics

industries.

Optimized

assembly and logistics processes for shorter delivery times

The machining centers that are constructed in

the CHIRON Precision Factory are not only characterized by maximum precision,

but also by faster availability. The machines are produced in a cluster

assembly process – one team, one machine – in shorter cycles. For each order,

the optimized processing saves about two to three weeks of time, so that

customers can get started with production sooner. And better too, thanks to

advance simulation of processes: All machining which is later carried out on

the machine can be programmed, simulated and optimized right in the Precision

Factory.

CHIRON campus at

the Neuhausen plant

The fact that CHIRON has accepted and

understood the challenges of the future is clear not only from the Precision

Factory itself, but also by the way in which it was achieved. It took just 15

months from the ground-breaking ceremony to the official opening. The

pioneering project was successfully completed within the specified time frame

and budget.

The

also new central logistics department at the Neuhausen plant combines the

CHIRON Precision Factory with the existing assembly halls to form a CHIRON campus.

CHIRON

Precision Factory - Facts

Construction time

July 2018 to September 2019 (ready for

occupancy)

Key building data

Capacity: Maximum of 400 machines per annum

Production

area: 9,000 m²

Logistics

area: 2,500 m²

Office

area: 2,200 m²

Total

area of the new building: 13,700 m²

Total

existing space: 17,000 m²

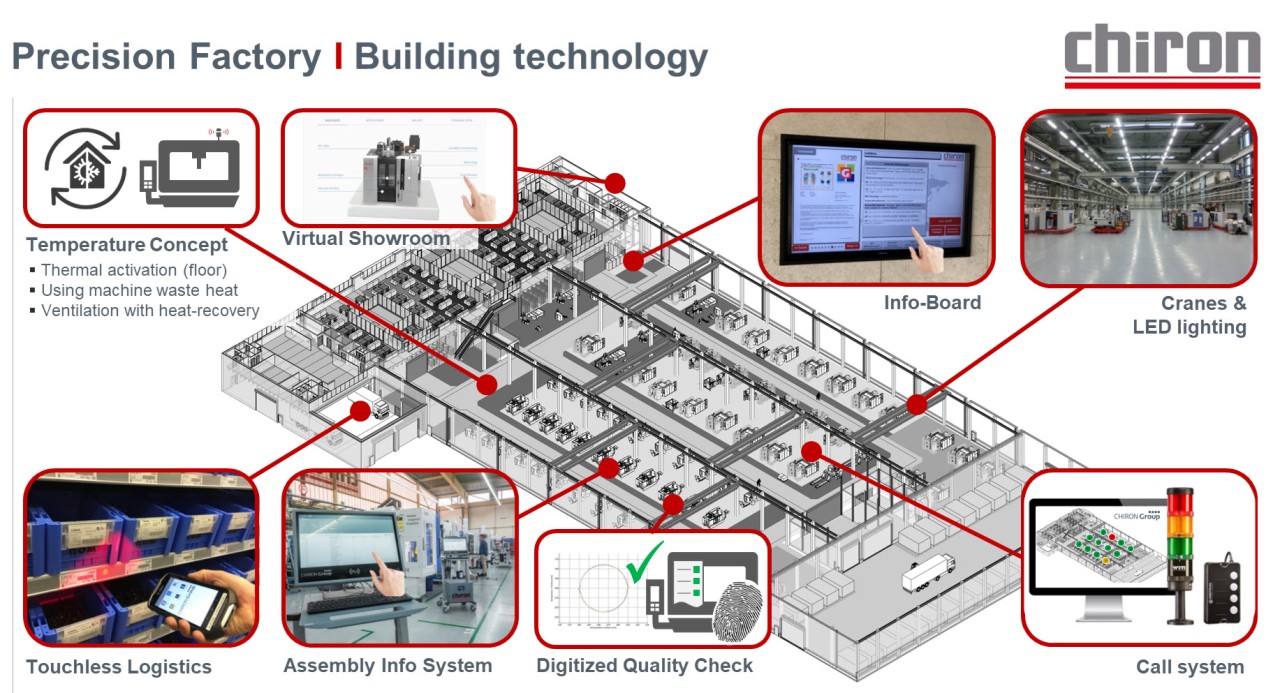

Layout

Optimal material flow configuration with

logistics spine for all flows of people and materials

Centralized final assemblies, engineering

offices and logistics areas

Central order picking of machines and systems

Building services

engineering

Concrete core activation for even and exact

temperature control

Use of waste heat from machines

Ventilation systems with heat recovery

LED lighting

Total energy consumption 70 kWh per m² and

per annum

Digitalization

Smart Factory

Cockpit: Control of air-conditioning, lighting and camera systems

Digital assistance

systems in assembly

Contactless

logistics bookings

Digital quality

testing and assurance ("digital fingerprint")