Globalization, demographic change,

dynamic technology development, digitalization and permanent innovations: These

megatrends have wide-reaching implications for production companies too. And

micromechanics is no exception. Both in the watch/jewelry industry and in

medical engineering, the objective is to achieve more flexible production with

maximum quality at reduced costs.

On both days, the specialist forum

focused on specific machining requirements. In his key note speech, for example,

Salvatore Ragusa, Managing Director of the Swiss precision engineering company

Concept CNC Design, reported on the filigree challenges in the production of

watch face overlays. For medical engineers, there were presentations on

flexible, intelligent production of instruments and implants, with

digitalization and additive manufacturing being important topics.

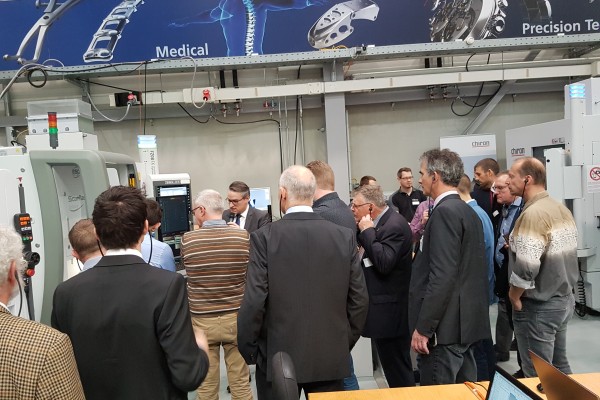

Overall, industry experts found out first-hand about

current trends and solutions throughout the process chain. In addition to the

host, CHIRON, other leading manufacturers of machining centers, tools and

peripheral devices gave concentrated presentations of their products and

services for micromechanics: C. Hafner, Concept CNC Design, Espi, Haas

Schleifmaschinen, HB Microtec, Hexagon, Louis Belet, Marquardt, Motorex,

Solidcam, Stäubli, Tornos, Trumpf and Yerly. For anyone who wasn't able to

attend in Tuttlingen on 27th-28th November, here is the conference

reader where you can read all of the presentations.