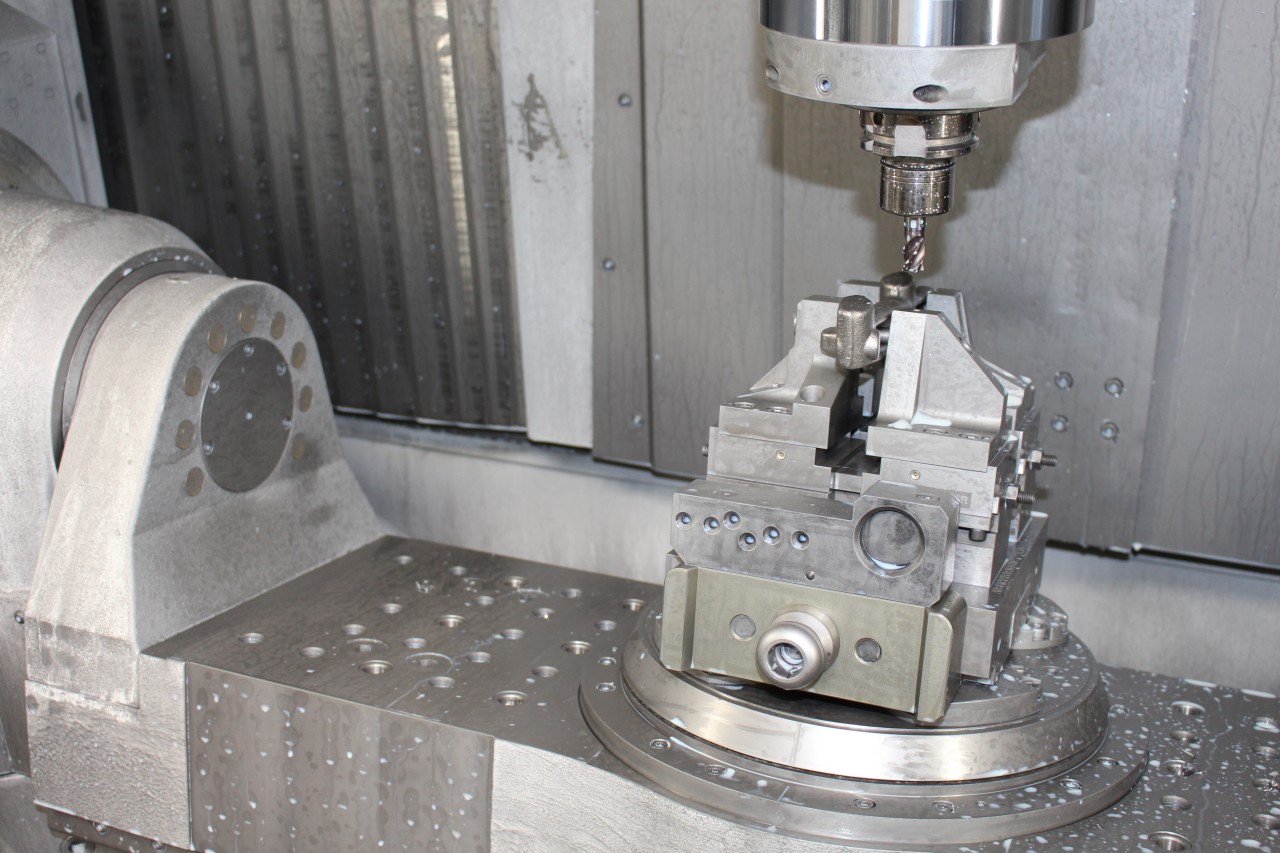

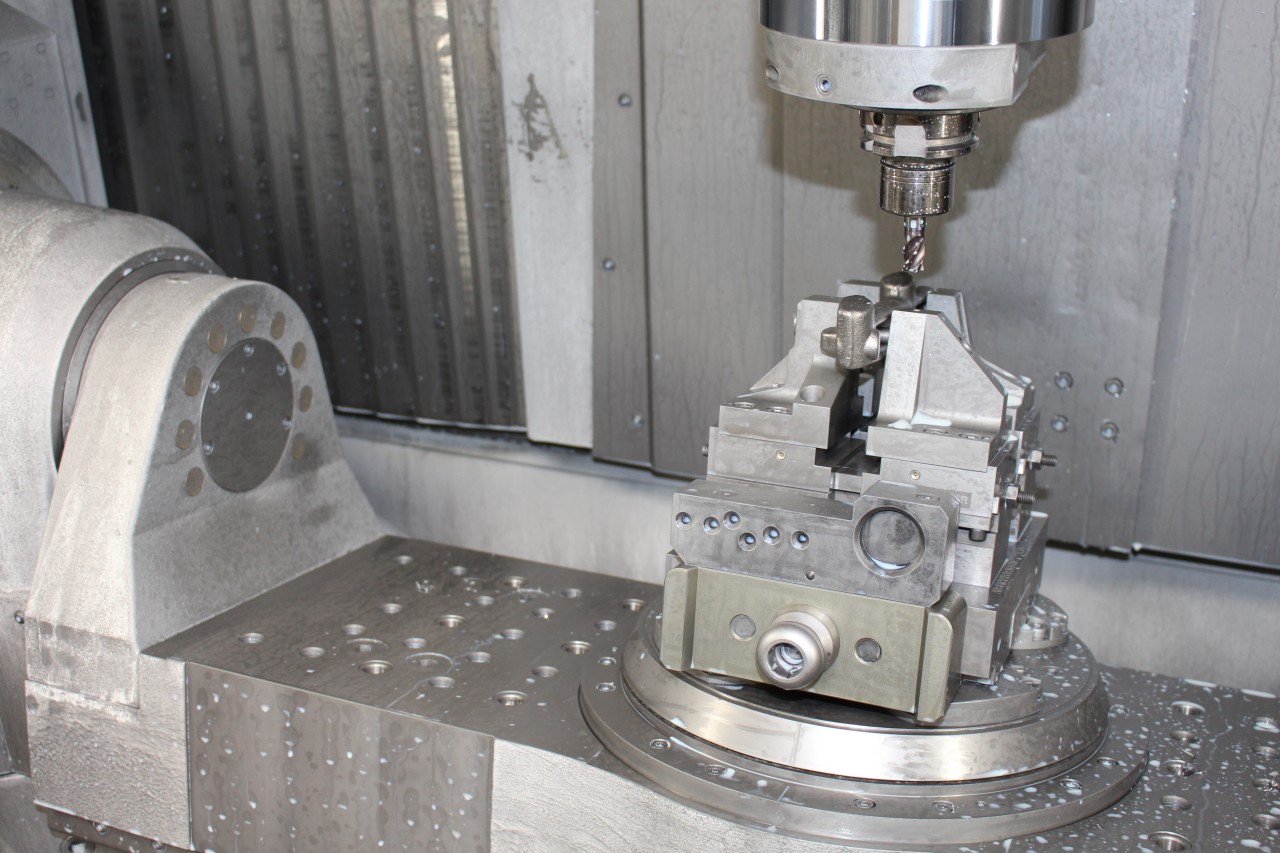

Machining a tail boom on the CHIRON FZ 15 S five axis machining center.

Many different components

but only small batch sizes: Motorcycle accessories manufacturer SW-MOTECH was

hunting for a suitable machining center to cope with the challenge of using

automation to manufacture 400 reoccurring parts in batch sizes of 30 to 200

pieces. »After we'd ascertained that all well-known machining center

manufacturers could mill well, it was the way the CHIRON Group took such great

care to understand our problems that finally made the difference,« says Kai

Jockel, Managing Director of SW-MOTECH GmbH & Co. KG and responsible for

production there. Together, they found a solution with the FZ 15 S five axis

machining center and designed a concept for the robots and clamping technology

which was appropriate to the variety of parts. The system has now been running

flawlessly in three-shift operation for a year. These are the most important

points of the application, but there's plenty more interesting things about the

project and customer.

First and foremost,

SW-MOTECH has interesting beginnings, with its origin on a ferry ride between

Italy and north Africa. In 1994, mechanical engineer Jürgen Swora developed a

tail tank for his Honda Africa Twin for a motorcycle ride to Libya that he was

taking with his friend Jörg Diehl. The bikers met on the ferry crossing to

north Africa, where there were not only lots of riders, but also a motorcycle

dealer who was interested in the tail tank.

»It was the way the CHIRON Group took such great care to understand our problems that finally made the difference.«

Kai Jockel

Managing Director of SW-MOTECH

A Honda Africa Twin has the starring role at the start of the SW-MOTECH story. The tail tank was constructed by the founder for a motorcycle tour through north Africa.

Everything started with the invention of a tail tank

From there, grew a

business idea which led to the founding of SW-MOTECH in 1999. The third member

on board was Kai Jockel, who remembers the time well, »We started back then on a

farm, in an old barn, with a drill and a welding device. Today, we have a headquarters

in Rauschenberg, in Hesse, Germany, 180 employees, a second production location

in Czechia and sales branches in Spain, France and now in the USA too.«

Right from the start, the

company focused on the production of premium motorcycle accessories produced

in-house. Our recipe for success was products that no-one else was offering,«

the managing director explains. Thus, in 2000, the first removable luggage rack

in the world, based on the Quick-Lock bayonet locking system, became their USP.

This was followed, five years later, by the patented Quick-Lock mechanism tank

ring for mounting a tank bag with just one click. »This pioneering product made

sure even the OEM motorcycle manufacturers knew who we were, when before we had

only supplied traders.«

The workload required a third machining center

And with that came new

requirements for production. While at the beginning, the majority of orders

were welded components, now increasing numbers of milled components were

needed. And so, the first three-axis machining center found its home at

SW-MOTECH. »With VCP 800 from Mikron, we very slowly started getting into

milling, only to then discover, quite quickly, that the machine was at full

capacity,« Jockel remembers. Then came the second three-axis milling machine

and, when that too was running around the clock, the company went to the EMO

2019, in Hanover, in search of another machining center. The slogan »Tool

change in 1.5 s« drew Jockel to the CHIRON Group stand at the exhibition.

»Although the speed, in this

respect, is not remotely relevant to us,« the Head of Production says with a

grin. »The part numbers in the motorcycle industry don't really compare to the

automotive industry. 30 parts is a typical batch size for us, and we also

wanted to mill prototypes or mechanisms on the new machine. However, we still

wanted automated manufacture of a wide range of parts.«

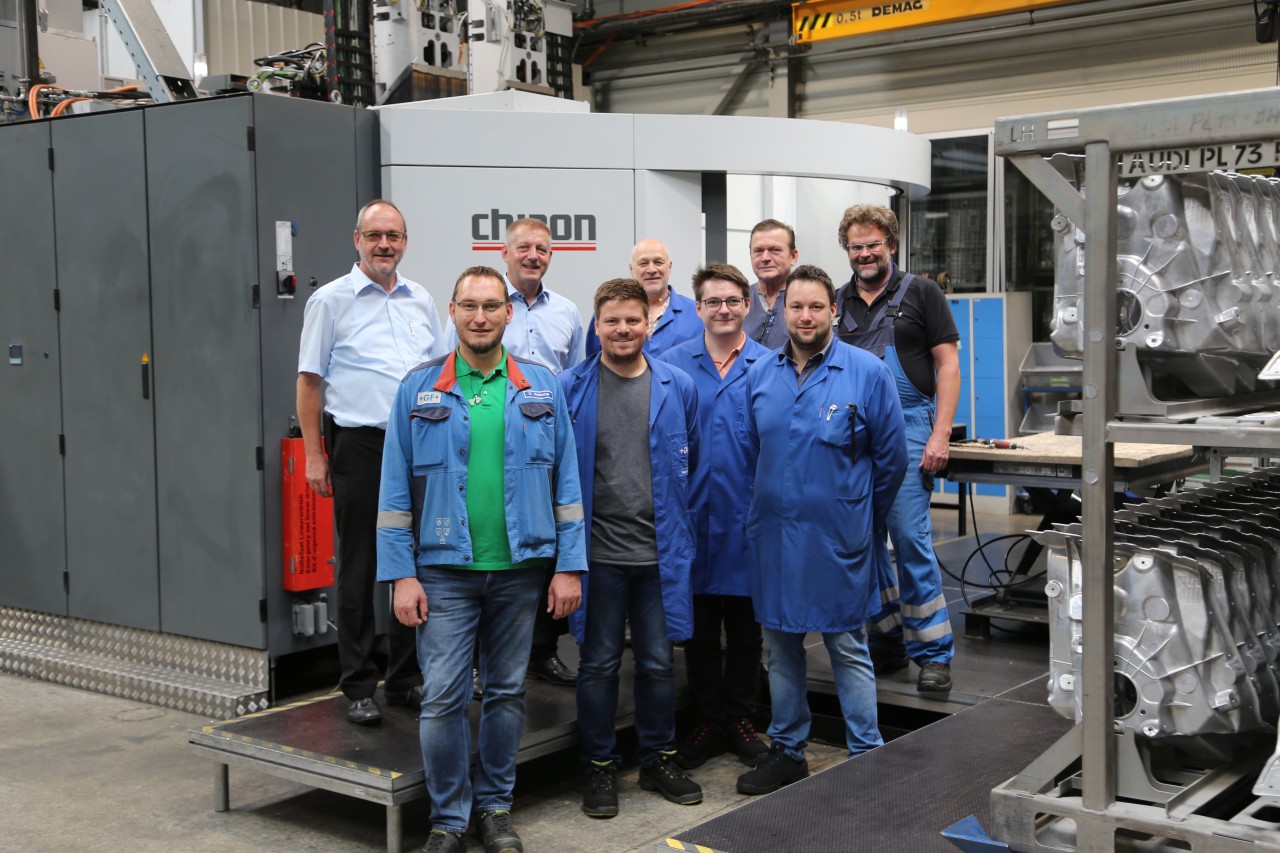

The decision makers in front of the successful system (from right): Kai Jockel, Managing Director SW-MOTECH, Roland Ranisch, Sales Partner at the CHIRON Group, and Bastian Feußner, responsible for machining.

The clamping concept

played a decisive role

That's why the clamping

concept, for the around 400 different components, played such a decisive role.

»We needed to find the balance between the level of investment for the machine

and for the mechanisms, because the workpiece side couldn't cost any more,« Roland

Ranisch, CHIRON Group Sales Partner, describes the initial situation. »So,

using a variety of mechanisms for each part, about half of which would only be

used once a year, wasn't an option.«

Together, they developed a

robot and clamping concept, which also required compromises on the part of

SW-MOTECH. The unmachined parts, or blanks, for certain component groups were

thus standardized, so that the same mechanism could be used more often.

»Because it's quicker to mill off 5 mm excess material from a blank, for

example, than to re-mount,« Ranisch explains. For Jockel, the be all and end

all was to remain with the vice as the final clamping element. »This meant we

only had to invest once in the base device with zero-point clamping system and

only need to adjust the second clamp at the top with the vice.«

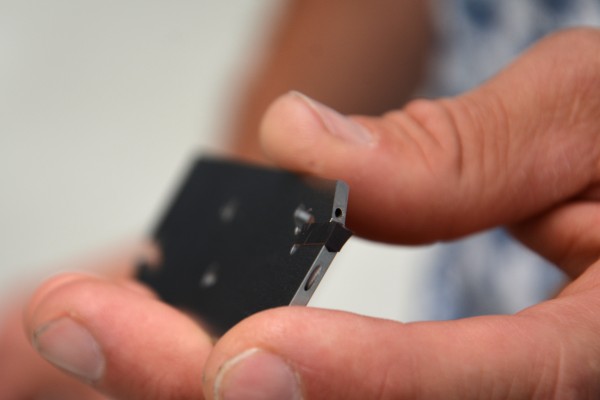

The gripper station has space for eight different grippers.

Rack with six device positions and a station for eight

double-grippers

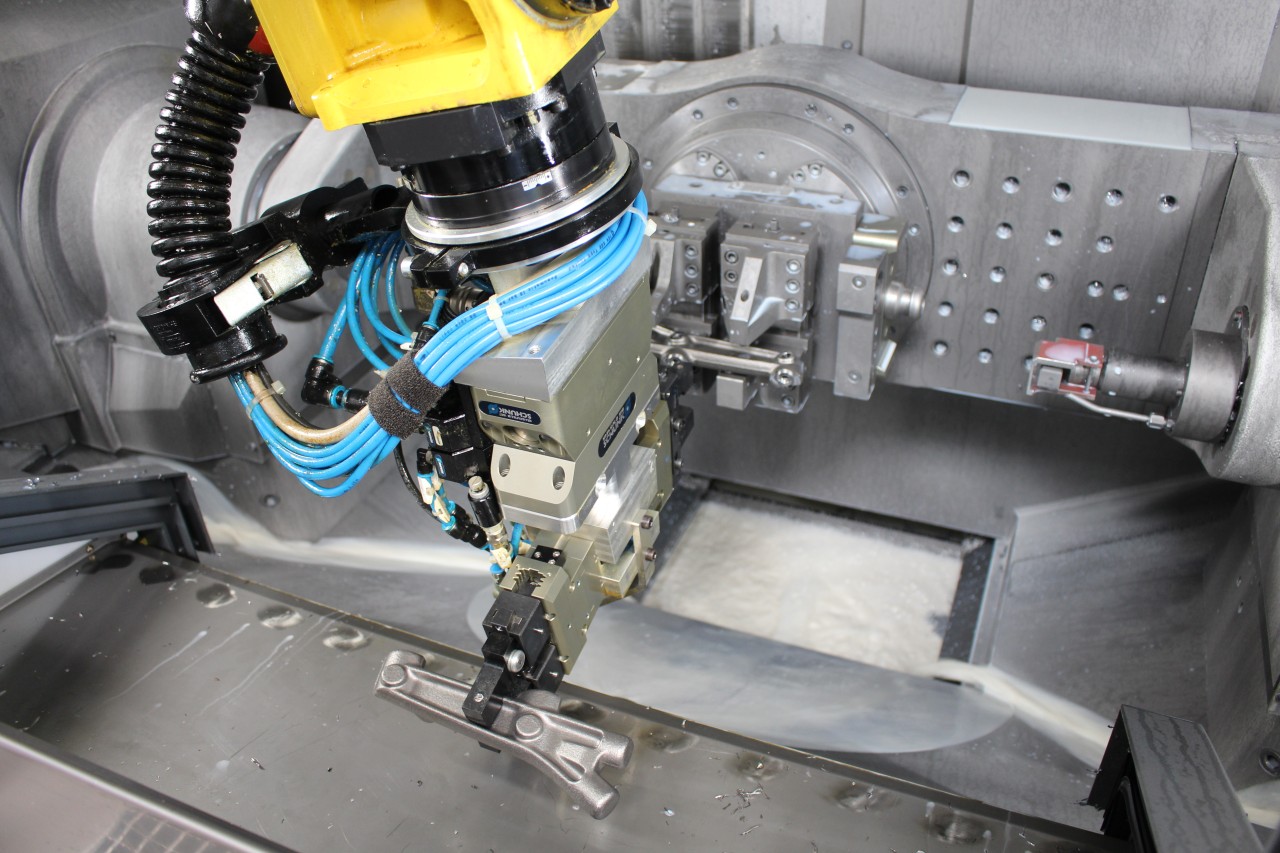

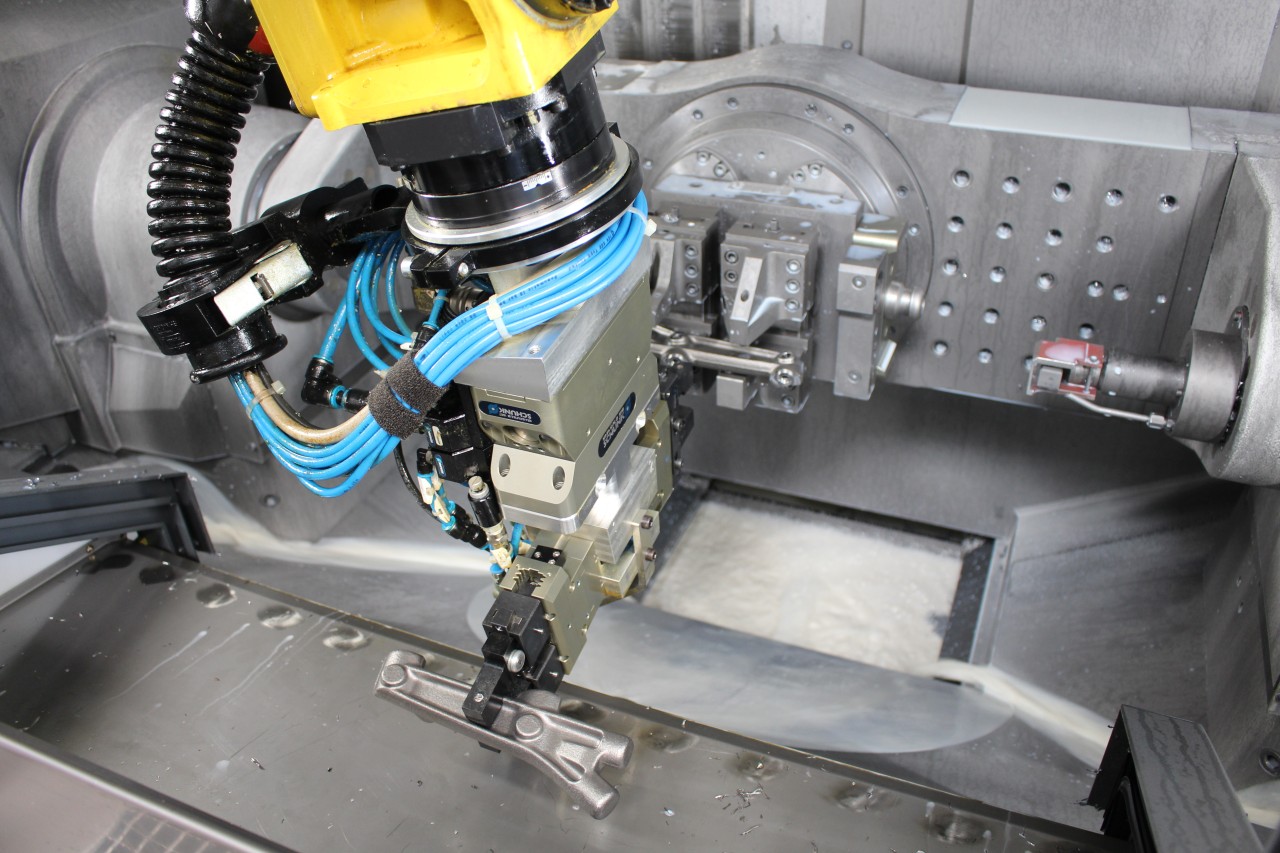

The final solution now

comprises a Fanuc robot, a paternoster rack with drawers for the blank part

pallets, a rack with six device positions and a gripper station for eight

double grippers.

The robot uses a double-gripper to change blank and finished parts.

»By using five-axis machining, we not only reduce the number of clamping position, we also have the opportunity to make expressive design parts on the motorcycle.«

Kai Jockel

Managing Director of SW-MOTECH

View from above of the complete machining cell in the SW-MOTECH Manufacturing department.

The pallets are 600 mm ×

400 mm and have space for up to 52 parts. »The store is designed for a runtime

of eight hours, with 24 pallets and, thanks to the six device positions, six

different components can be machined per shift without operators needing to

manually interfere. The average machining time is three to four minutes,«

Ranisch describes normal operation. Bastian Feußner, who is responsible for

machining, describes the process of changing products, »The robot takes the

device out of the machining center, changes it for a new one and then takes the

gripper with the correct clamps. The pallet with the new blanks is prepared

from the paternoster rack and the robot places the part in the machine. The

following step, thanks to the double-gripper, is when the robot takes the

finished component and places the blank part in. The production order always

specifies whether the necessary devices and gripper are in the racks. A

complete switch over takes around five to six minutes.«

The number of clamping positions needed to be reduced

Choosing the machine

itself was relatively simple, and they decided on the FZ 15 S five axis

machining center because it was best suited to the range of components. There

was, of course, a reason that it had to be five-axis this time. Managing

Director Jockel explains, »We often needed up to four clamping positions for

our three-axis machines. Five-axis machining allowed us to not just reduce the

number of clamping positions, but also gave us more options for more expressive

design parts on the motorcycle.«

The acceptance parts were milled in the required quality

The CHIRON 15 Series

machining centers are fundamentally standard machines, but the options catalog

includes around 300 positions for individualization. »For SW-MOTECH, because of

the customer-specific design on the workpiece-side it was, again, a turnkey

project, including acceptance and production monitoring,« says Ranisch. A

forged part for a frame and an aluminum profile were milled to the required

surface quality and precision, and after three weeks of support from a Chiron

application engineer, SW-MOTECH was able to operate the system without aid.

Now, that really is the

whole story and all that's left is to sum up. Here, the experts Kai Jockel and

Bastian Feußner thoroughly agree, »The system makes what it's meant to make and

has run without a hitch since installation. And that's just how we like it.«

For more information: https://www.SW-MOTECH.info/en/

Everything motorcycles

In 1999, three motorcycle

riders and enthusiasts, Jürgen Swora, Jörg Diehl and Kai Jockel, founded

SW-MOTECH GmbH & Co. KG in an old barn. Today, it is a top global provider

of motorcycle accessories. The company became known for the first removable

luggage rack and the patented Quick-Lock tank ring for mounting tank bags.

Nowadays, the portfolio comprises over 3000 brand products which are exported

to over 70 countries.

These include side and

tail-mounted luggage solutions, as well as protective and safety equipment,

accessories for ergonomics, navigation, and seat-attachments.

Over 300 employees work in

the headquarters in Rauschenberg, Hesse, and in another plant in Brno in

Czechia. The company prides itself on producing premium motorcycle accessories

from conception to design and prototyping, right through to series production,

sales and customer service.