Author:

Georg Schöpf, x-technik FERTIGUNGSTECHNIK

Automotive suppliers have

the challenge of complying with the ever-increasing demands of the OEMs. Large

batch sizes of components need to be delivered, just in time, with

reproduceable, ever-higher quality. Lightweight construction is of increasing

importance and, therefore, so is the manufacture of bigger, lightweight

structural components made from aluminum and magnesium.

Task assigned

Post-processing of

high-pressure die-cast components.

Material

Aluminum, magnesium

Solution

Twin-spindle milling

machining center DZ 25 P from the CHIRON Group.

Advantages

Short cycle times with

high precision and reliability.

GF Casting Solutions

Altenmarkt GmbH & Co. KG is a premium supplier for this kind of part. The

firm was founded in Austria in 1972, under the name Alucon, and later was

operated by Mössner Druckguss. It has been part of GF Corporation since 1999.

For over 20 years, the firm has focused on manufacturing components for

automotive production. Product and process development for high-pressure

die-cast components is one of its specialties. »We are constantly facing the

challenge of manufacturing bigger and bigger components. To keep the weight of

the components as low as possible, you end up with die cast parts with low wall

thickness, which creates its own challenges for high-pressure die-casting and

manufacture,« explains Reinhold Brunnthaler, Senior Expert for Mechanical

Machining at GF Casting Solutions. Over the years, the experts in high-pressure

die-casting, from Styria, Austria, have expanded their knowledge and expertise

for the necessary process steps. Now, they're in the position to offer the

entire value chain, from simulation to high-pressure die-casting to mechanical

machining and part coating, as well as checking for efficiency, and seamlessly

documenting the entire process.

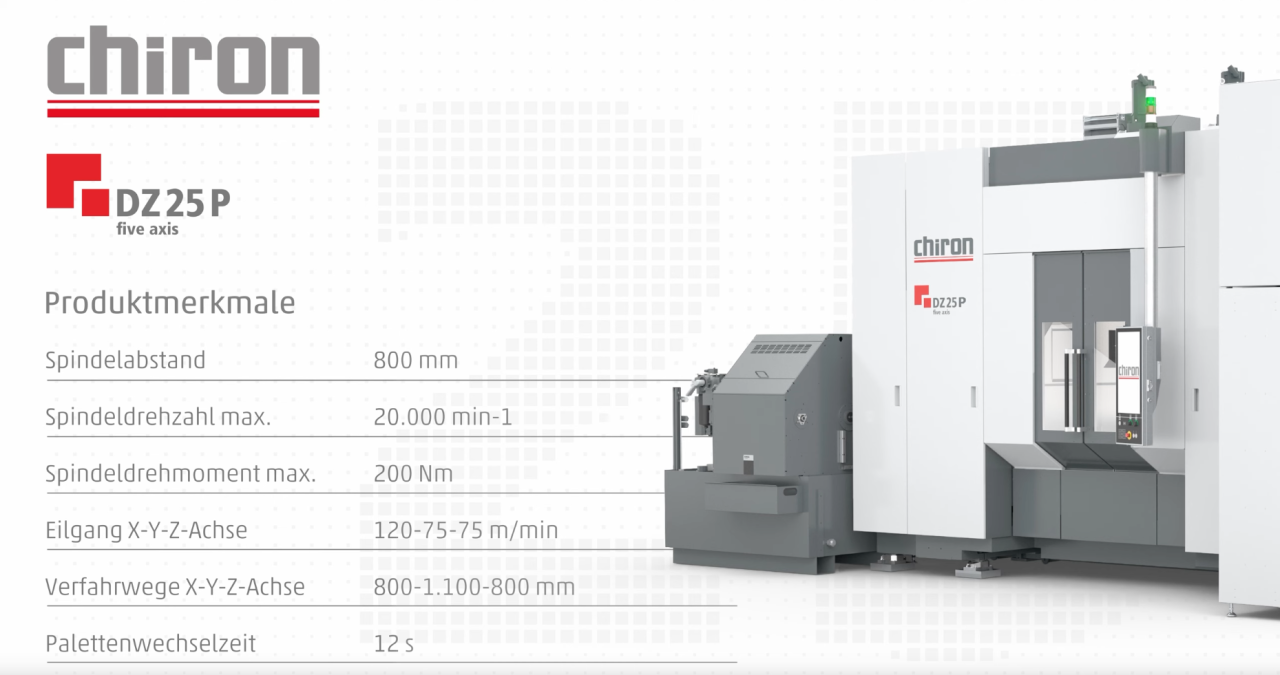

The benefits of the 25 Series at a glance

Twin-spindle machining of

large-volume components

Optimum dynamics

Best possible access to

the working chamber

ndependent X-axis and

Z-axis compensation

Process easily visible

thanks to separation of the operating and loading sides

Compact, flexible machine

layout

Intuitive operation via

TouchLine

Automation

via robots or gantry

High level of in-house production

»Our

services cover all process steps right up to ready-to-mount components, and we

have all the necessary machining methods in-house. Cutting plays an important

role in this. Our fleet of machines comprises almost 50 machining centers. With

high-pressure die-cast machines with closing forces of up to 4,400 t, we

machine nearly 14,000 t of aluminum and magnesium per year and each part

requires some form of post-processing«, Brunnthaler justifies the high capacity

requirements.

»Working together with the CHIRON Group development team allowed us to create a machine that perfectly fits the profile of our orders. In the end, it far outdid our initial list of requirements and meets all our needs, even regarding precision.«

Reinhold Brunnthaler

Senior Expert for Mechanical Machining at GF Casting Solutions in Altenmarkt

Customized solutions

The

CHIRON DZ 25 P twin-spindle machining center, which was first put into

operation in February 2020, has a development story that fits perfectly with

the process development objective of the GF Casting Solutions site. Dirk

Schmid, Head of technical Sales Germany, Austria, Switzerland at the CHIRON Group

SE, remembers »We've been working with Georg Fischer for over ten years now.

There are more than 15 machines of the CHIRON Group working at the site in

Herzogenburg and in Altenmarkt. We knew that the requirements for batch sizes

and the dimension of the parts were constantly increasing. Because we wanted to

support customers like GF to work more efficiently, we asked GF in 2015,

whether they were interested in helping us develop a highly productive,

twin-spindle machining center.«

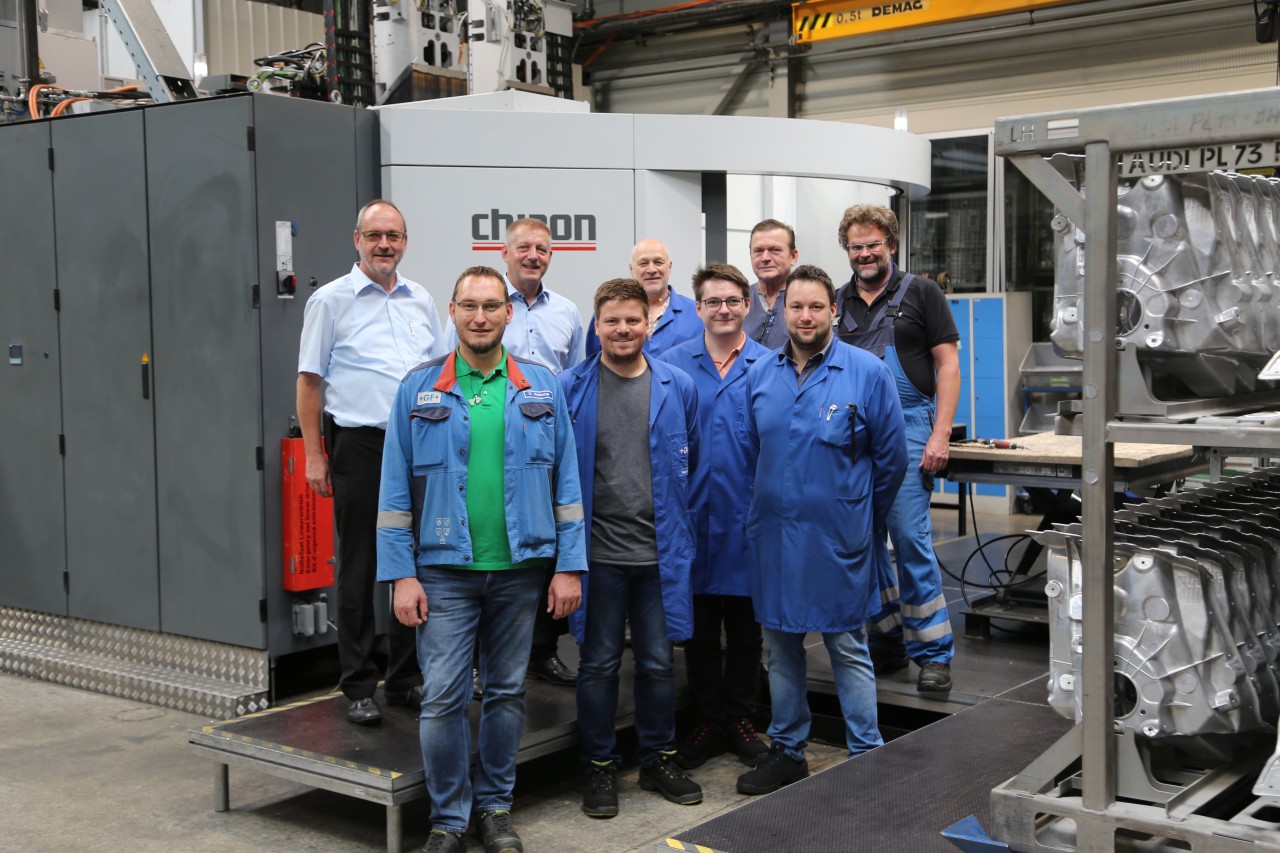

Loading and unloading during operation using pallet changers guarantees high levels of efficiency.

GF Casting Solutions in Altenmarkt specialized in the manufacture of high-pressure die-cast components made from aluminum and magnesium for the automotive industry. These are produced in a wide range of batch sizes depending on requirements.

»We wanted to bring a machine onto the market that was perfectly tailored to the requirements of the automotive and aviation industry. Operators like GF Casting Solutions were the perfect development partner for this. The 25 Series unites stability, dynamism and precision.«

Dirk Schmid

Head of technical Sales Germany, Austria, Switzerland at the CHIRON Group SE

The aim was to develop a

manufacturing system precisely tailored to the needs of automotive suppliers

for machining structural components. »We compiled a feature list with a precise

profile of requirements for a new, twin-spindle machine concept. Of course, we

started from the necessary machining steps, but we also rethought the

composition of the machine from scratch. A shuttle table concept for equipping

the machine during operation, as well as a quick tool changer for reduced

change times. We also had to keep in mind the high safety requirements,«

Brunnthaler goes into detail about the design.

Prioritizing stability and ergonomics

The main focus was on

highly productive machining of complex structural components. This was one of

the reasons that the CHIRON Group opted for mobile gantry design for the new

development, rather than the tried-and-tested a traveling column design. »The result

was an extraordinarily stable and rigid machining center which also fulfills

all our wishes in terms of precision. We found out precisely which factors are

relevant for cycle times and focused on those in particular. It became clear

that tool changing and workpiece positioning were crucial aspects for this,«

Schmid says. The turntables, mounted in parallel on the bridge of the A-axis

with an 800 mm spindle distance, can be fitted on the loading space and

swiveled in. Both HS motor spindles run on independent Z-guides, enabling

mirror machining and compensation of possible component distortion.

Experts from both the CHIRON Group and GF Casting Solutions worked together on the development project. (rear, from left to right) Wolfgang Prokopp, Dirk Schmid, both CHIRON Group; Dieter Brenner, Reinhold Brunnthaler, Frank Otto, all GF Casting Solutions; (front, from left to right) Michael Hintsteiner, Mathias Ahrer, Christian Fellner, Christian Platzer, all GF Casting Solutions.

Capacity for high productivity

The significant rigidity

of the machine allows high dynamics and very fast axis acceleration, as well as

fast rapid traverse speeds. Two separate tool magazines with space for 60 tools

each, offer independent tool change on each spindle for short Chip-to-Chip

times of 3.5 s. With axes of 800 x 1,100 x 800 mm (X/Y/Z), it's easy to machine

large parts and the spindle torque of 200 Nm at 20,000 rpm is transferred

safely to the tool via a HSK-A63 interface. The new TouchLine operating panel

is based on a Siemens 840 D sl.

»The positive experiences

with CHIRON machining centers allowed us to win GF Casting Solutions Altenmarkt

as a development partner for the new structural component machine. The previous

machines are, for the most part, also universal. The DZ 25 P is one of the

newest developments from the CHIRON Group, ideal for structural components for

the automotive industry. It's a true workhorse in terms of performance,

productivity and reliability,« Dirk Schmid looks satisfied as he finishes his

explanation. Reinhold Brunnthaler adds, »Our cooperation with the CHIRON Group

was really very fruitful. We regularly refined the details together with

developers until the set-up was thoroughly perfect. During the installation

test phase we actually produced suspension struts for Audi and then immediately

moved to three-shift operation. This helps us achieve the current rates of

around 270 parts per shift; which is a huge increase in productivity compared

to the old system.«

The CHIRON

Group also offers a solution for larger structural components now, with the DZ

25 P in one size bigger. The new 28 Series with 1,200 mm spindle distance

perfectly complements the CHIRON Group portfolio. Based on the same machine

platform, the new CHIRON series are precisely designed for the various

workpiece dimensions, covering the whole range of sizes and complex components

for automotive and aerospace applications.

GF Casting Solutions

Altenmarkt GmbH & Co. KG was founded in 1972 in Obersteiermark (Austria),

under the name Alucon, and was later run by Mössner Druckguss. In 1999, Georg

Fischer took over the plant and, since then, it has been manufacturing

high-pressure die-cast components from aluminum and magnesium, primarily

serving the automotive industry from its base in Altenmarkt. Around 600

employees manufacture 14,000 t aluminum and magnesium each year on

23 high-pressure die-casting machines. 47 machining centers and numerous

specialized machines, heat treatment systems, coating systems and laser,

grinding and deburring cells complete the fleet.

www.gfcs.com/en