The CHIRON Group's

machining centers enable precise, productive and flexible manufacturing in the

automotive, aerospace, mechanical engineering, medical technology, tool

manufacturing and precision technology industries. The fact that the company

has these areas of expertise is no accident but the result of »continuity in

mechanical engineering, combined with drastic change in technology and the

product range,« says Dr. Armin Schmiederberg, Chairman of the Board at the

CHIRON Group SE.

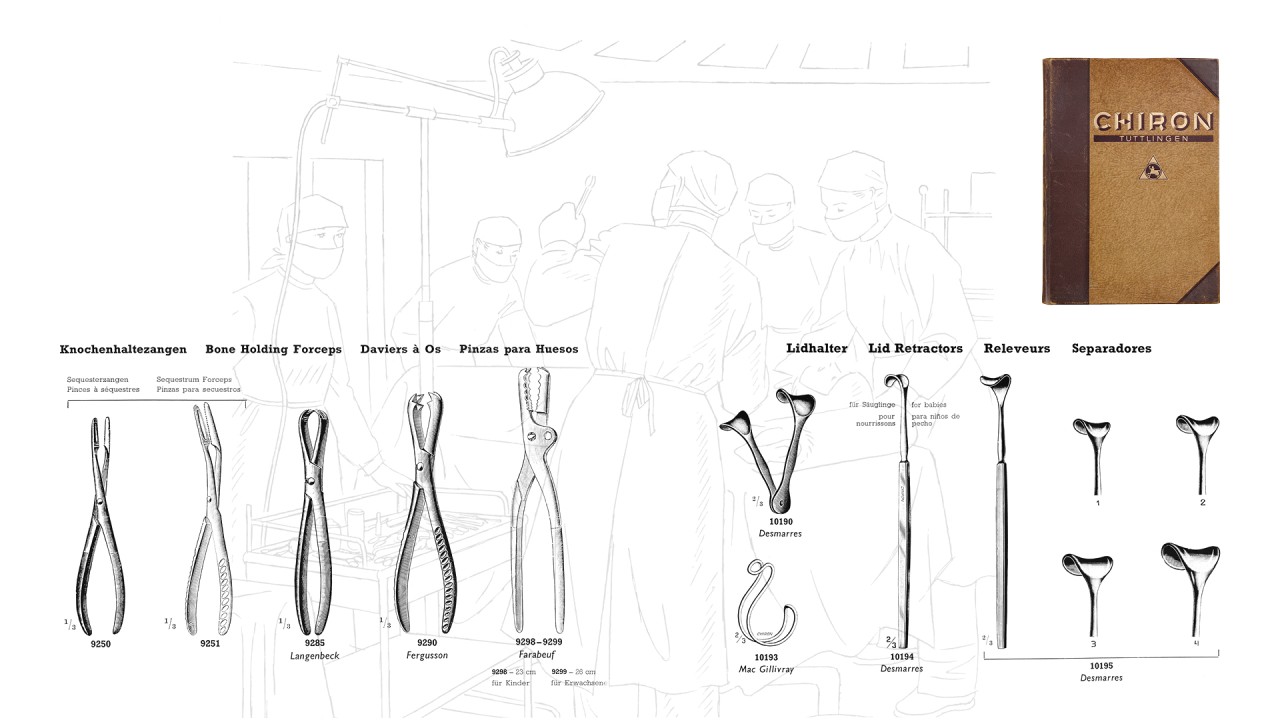

»It's noteworthy that CHIRON has created a new product range three times [...]: Surgical equipment, pressurized-air devices and machining centers.«

CHIRON publication »Recollections – The history of a company«, 2016

Where

everything began: Surgical equipment

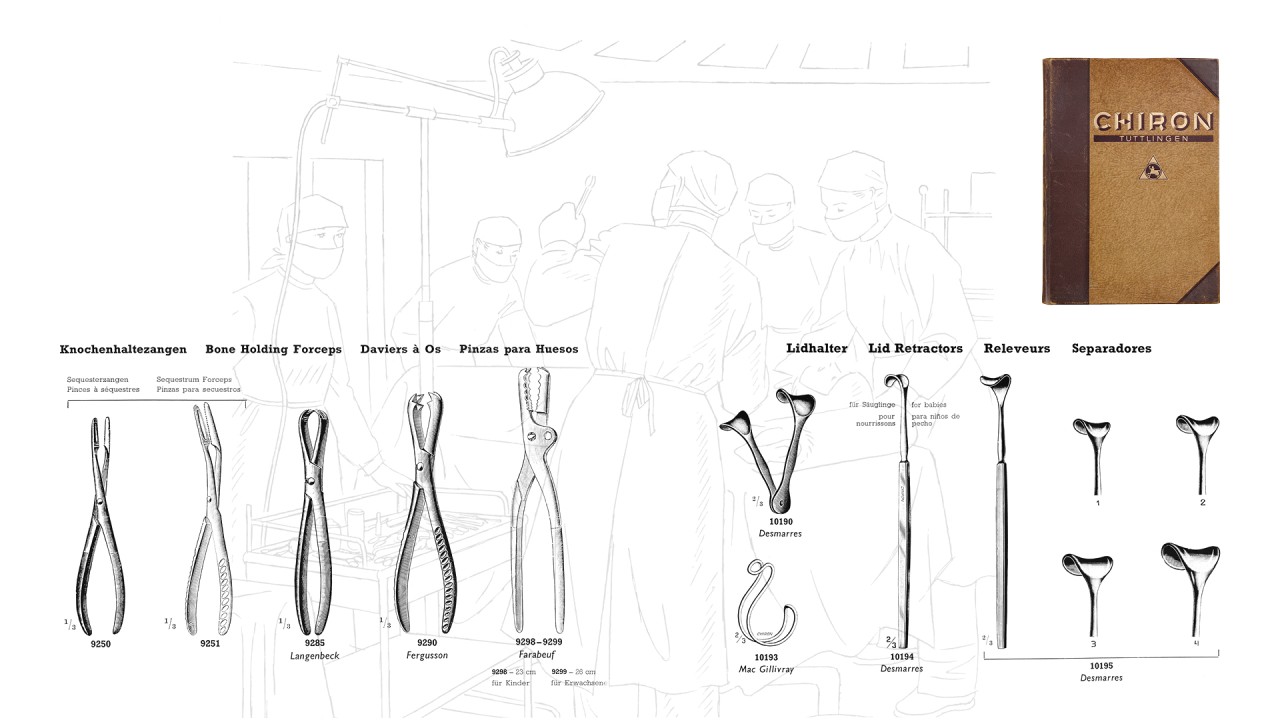

»Fabriken für feinmechanische Apparate und chirurgische

Instrumente GmbH« – a precision appliance and surgical instrument manufacturing

company – was founded by Otto Staebler and Gottfried Schnell in 1921. This was

made possible by the invention of »stainless steel« in 1912 and the filing of

another patent by Friedrich Krupp AG in 1919 which permitted stainless steel to

be used in medicine. Both of the founders were quick to recognize the huge

potential of this material revolution. The company went on to produce

instruments that had not previously existed, which were precise, extremely

sharp, stable and could be sterilized without any difficulty. By the end of the

1930s, the product range already comprised around 30,000 medical technology

products. CHIRON, together with other companies, established Tuttlingen's

reputation as the »global center of medical technology« and would continue to

offer this product line into the 1970s.

Over 562 pages, the main catalog No. 10 from the 1930s listed everything that could possibly be needed in practices and clinics as »the reliable assistants«. Around 30,000 medical technology products were listed, including retractors, blood-letting tools and chloroform instruments.

»All employees really contributed to the company becoming a world leader in the manufacture of surgical instruments, where precision and exceptional Swedish steel come together.«

Dr. Ursula Hatzelmann-Kick (née Schnell)

granddaughter of CHIRON founder Gottfried Schnell

What remained after the company's sale to Aesculap AG in

1977 was the extensive expertise that it had gained over decades concerning the

industry's complex requirements. This expertise was then incorporated into the

manufacturing technology used to produce medical technology products with a

precise and high-quality surface finish in a reproducible manner. Examples of

this are the precision+ machining centers from the CHIRON brand and the Medical

& Precision Technology Center, which was opened in 2013 at the headquarters

in Tuttlingen, Germany. This is where production-ready complete solutions made

up of machining centers, tools, clamping mechanisms and automation systems are

produced.

The Medical & Precision Technology Center at the headquarters in Tuttlingen, Germany. This is where production-ready complete solutions made up of machining centers, tools, clamping mechanisms and automation systems for medical technology products are produced.

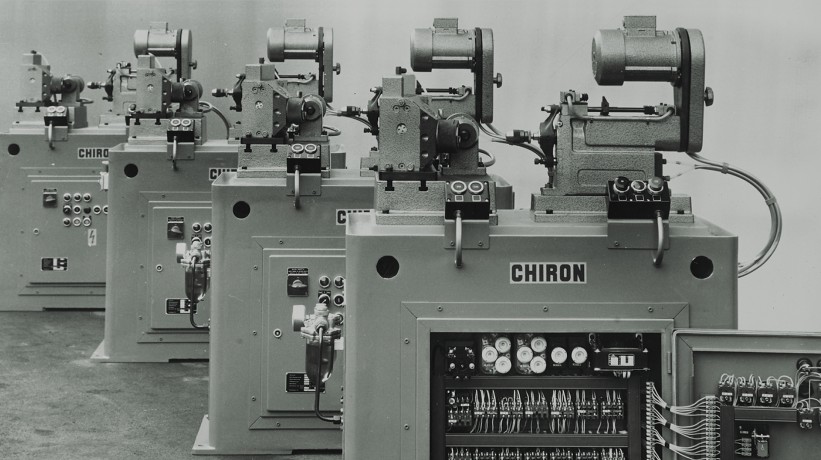

Compressors:

CHIRON gives itself breathing room

The business

area of compressors started in the early 1950s with the production of

compressors for installation in trucks for the French army and Daimler-Benz and

was initially just one of many answers to the question – what can we produce

with our limited production means? CHIRON recognized that there was

significantly greater potential in compressors and pressurized-air devices than

in portable typewriters, tedders, car washing systems, hat dryers and similar

unconventional items and systematically expanded the new business area. The

product range soon extended from compressors for installation to stationary

compressor systems for a wide range of markets. For example, it included the

CHIRON-Luftikus 200, a »multipurpose compressor system« for domestic use, crop

protection devices and paint spray guns for industry and trades. High

performance, a compact design and easy access are just some of the compressors'

advantages. These are qualities that are characteristic of CHIRON across all

product areas and continue to similarly make the CHIRON Group's machining

centers stand out from the competition to this day.

Another typical quality of CHIRON is that it intensively

engages with topics. Every year, and with each new product, the Development and

Production departments at CHIRON learned more and more about their machine

inventory. They learned which adjusting screws to turn and how to improve the

systems for metalworking so that the products were of the highest quality. This

allowed them to gradually build up expertise and they increasingly focused on

the production of compressors and low-pressure devices.

Concentration was also key during the period after CHIRON's

takeover by Hoberg & Driesch GmbH in 1957. Peter Hoberg and Toni Driesch

recognized the company's in-depth expertise in mechanical engineering that it

had built up over decades. As such, other firms' machines were adapted to the

relevant machining tasks, converted and had their functions extended. The

technicians and engineers in the R&D department had the necessary

expertise, they were innovative and flexible, and everyone in the installation

team was well-versed in the various manufacturing operations. Now, they could pool

their strengths and transfer their practical expertise to building machines.

New business

area of machining centers

CHIRON presented its first feed units for metalworking in

as early as 1958 and then further developed these units into specialized

machines for machining processes. Based on its knowledge about the specific

requirements of customers – and they had been customers of the machine

manufacturer for long enough to know – CHIRON created the perfect, individually

tailored, complete solution. Machine components, mechanisms, workbenches and

tools were combined and adjusted in such a way to enable high volumes to be

manufactured precisely and efficiently. CHIRON sold the first 801 – the first

machine and first model from the legendary series – to Roland-Werke. This

marked the start of a long series of customer-specific machining units and, if

you will, also the start of CHIRON's expertise in turnkey solutions – a service

that the CHIRON Group still provides today.

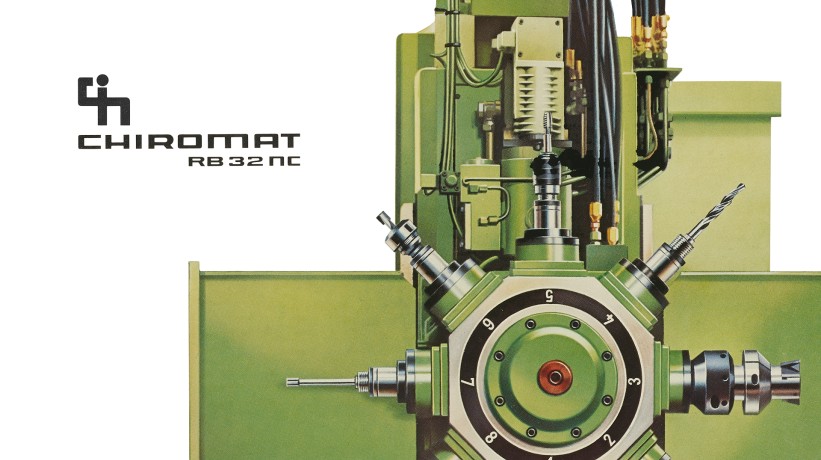

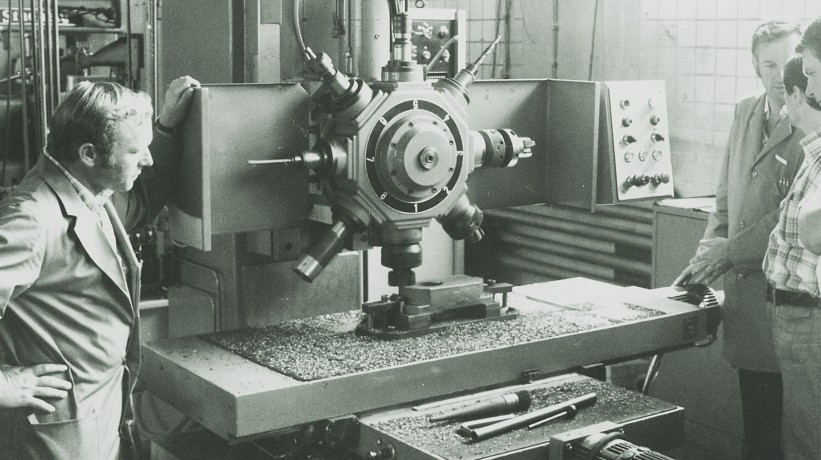

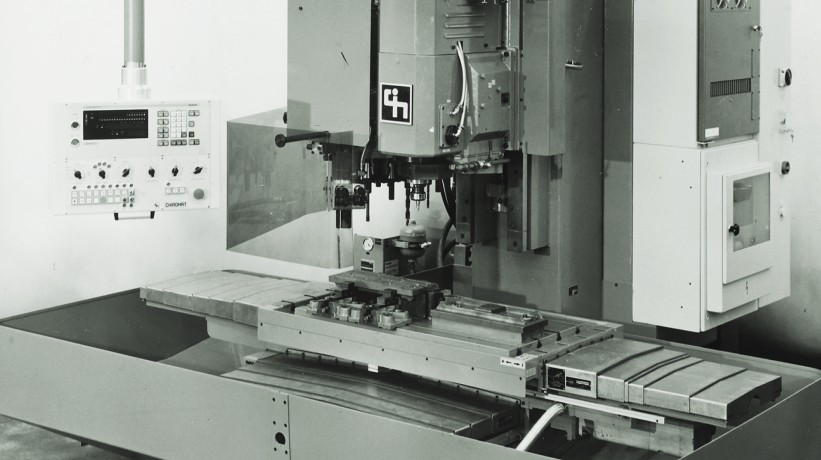

Four letters, two numbers and much more – in 1973, CHIRON

showcased its first in-house innovation, the CHIROMAT RB 32 NC. This again

demonstrated how quick the company was to recognize potential and to apply it

to practical solutions. The eight-spindle turret-head drilling machine was the

first system on the market to have numerical control. Soon after, CHIRON

established CNC technology, which was still in its infancy. This allowed

significantly faster movement of axes and tools, making for more efficient

individual and series production for customers. With the RB 32 and the

subsequent models, CHIRON had definitively positioned itself as a machine tool

manufacturer and had again successfully undergone a transformation.

From

machining units, components and bench drills, to specialized machines, NC

manufacturing centers and machining centers – one development led to another

and with every new product division and every customer-specific manufacturing

task, the mechanical engineering expertise within CHIRON was further

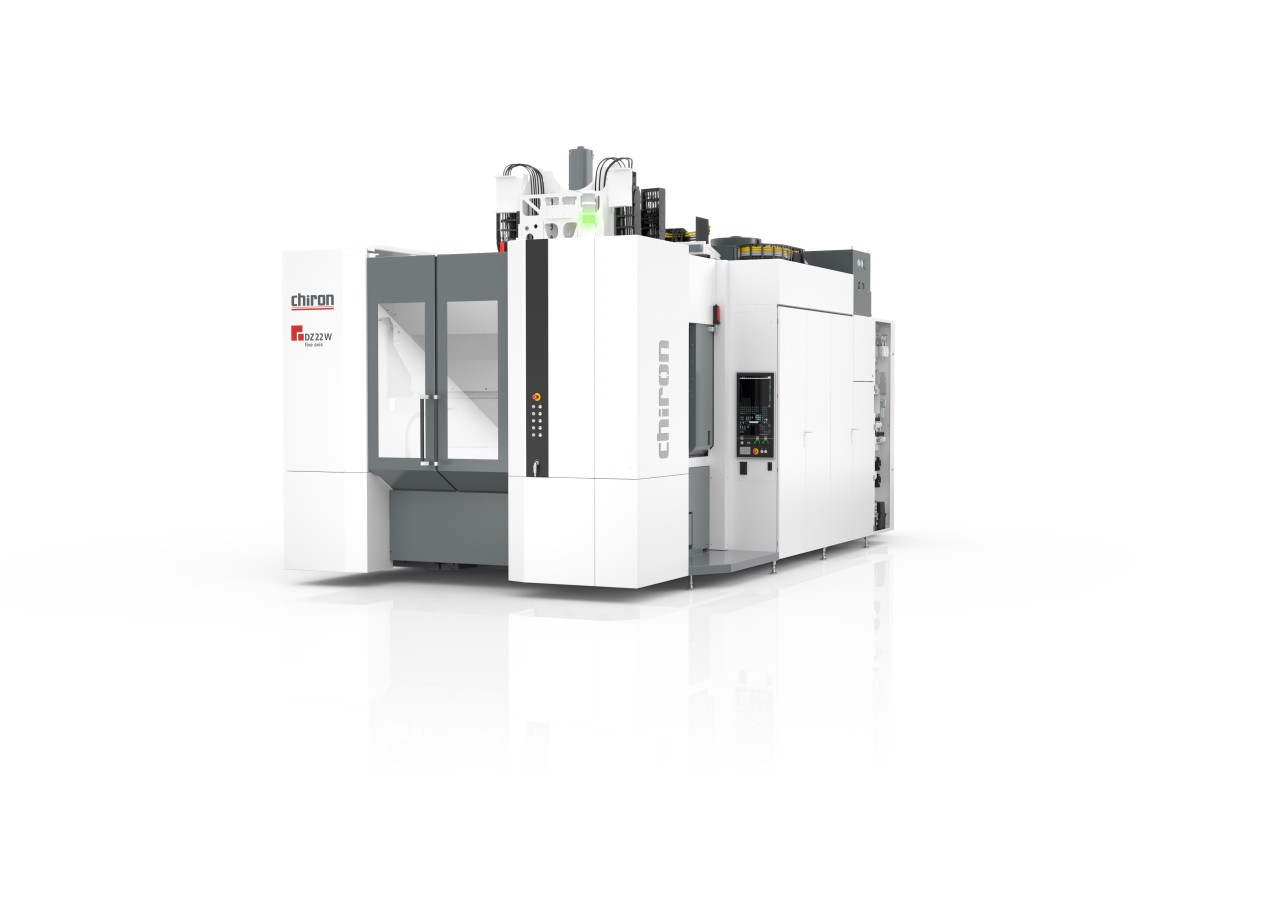

developing. With its innovative products and services, the CHIRON Group now

facilitates precise, productive and flexible machining in many different

industries. In addition, the company is now staying ahead of the competition by

establishing new areas of expertise and developing new products that take

customers' manufacturing processes forward – such as additive manufacturing,

digital systems and services.

The company's industry expertise in medical technology,

precision technology, mechanical engineering and tool manufacturing is drawn

from its present and past product ranges. Similarly, the company's automotive

department also has interesting links to the past.

From amphibious

to automotive vehicles

From

the »Ruck-Zuck« tire lever, to the »Pneumoskop« for checking the tire pressure

gage and car washing systems – over decades, CHIRON brought a variety of

products onto the market that were related to vehicles in the broadest sense.

The company was also quick to recognize potential in this area, but, with the

»Trippelwagen« amphibious vehicle, they were maybe slightly too early. »I think

that in developing a quick but economical car, Hans Trippel was way ahead of

his time«, concludes Erwin Liebermann, who worked at CHIRON between 1944 and

1992.

The

Trippel SK 10, developed by the son-in-law of Managing Director Fritz Kiehn in

the late 1940s, was supposed to bring CHIRON great market success and create many

new jobs. The vehicle had all of the features needed to be a hit, from a top

speed of 95 km/h, to fuel consumption of just 3.2 l per 100 km and a sporty and

streamlined design. Unfortunately, success did not come and the Trippel left

the plant site on May 8, 1951, with many eyes admiring it.

Many

employees also felt like they wanted to take the company in a new direction in

the automotive sector, for example, by developing machining centers for wheels.

In 1993, CHIRON brought the WM 02, the first »real« wheel machine, onto the

market and the CHIRON Group now manufactures machines for rim diameters of

between 16 and 26 inches. These machines work 24/7 and produce between 250,000

and 350,000 wheels per year.

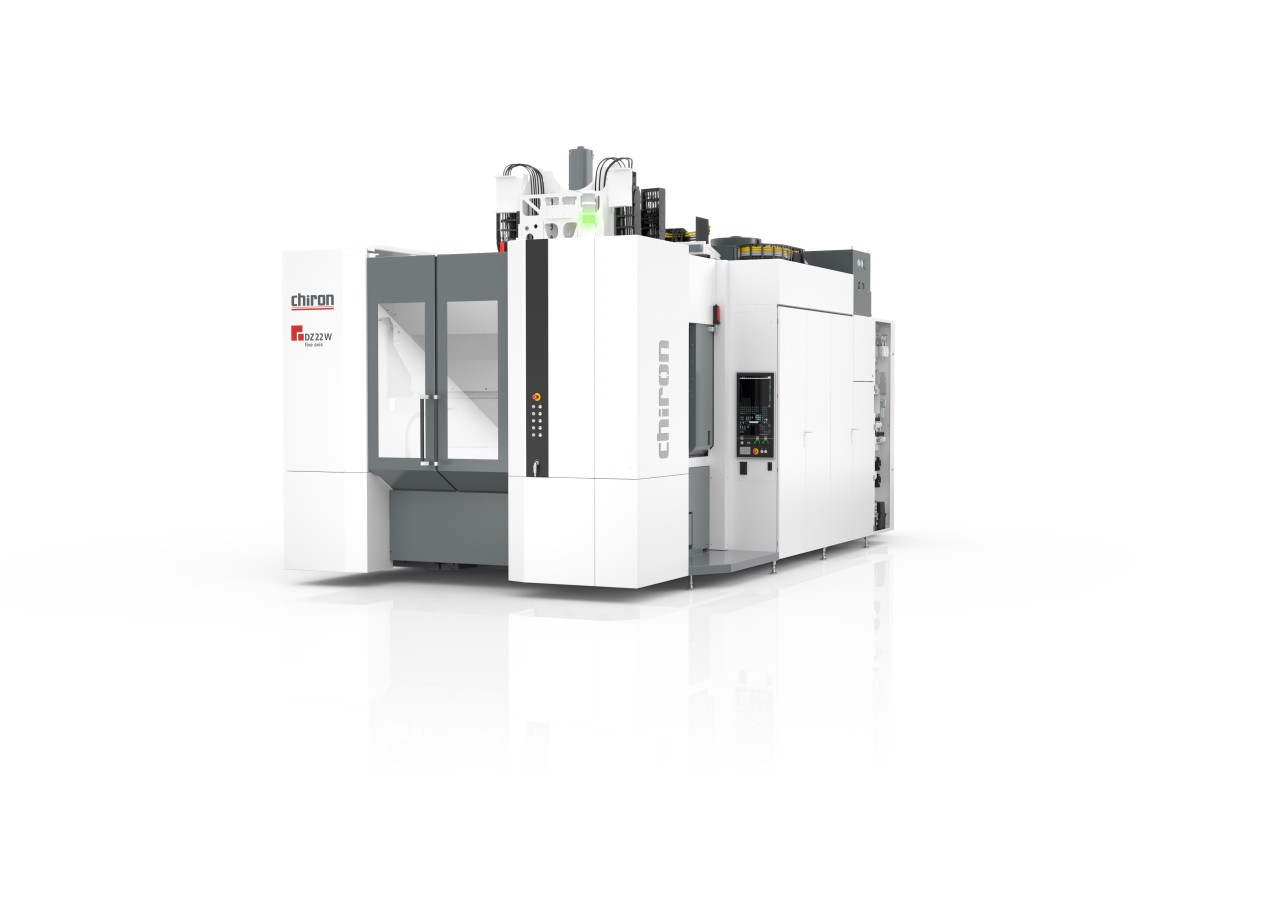

Moreover,

the company also offers manufacturing centers for the 22, 25 and 28 Series.

These centers machine large and complex parts for the growth market of electric

mobility in a highly efficient manner.

The first wheel machine, the WM 02, with all machining options for wheels of up to 16 inches in diameter.

In use since 2013: The FZ 18 S five axis, designed for robust machining of truck wheels of up to 26 inches in diameter.

The new CHIRON 22, 25, and 28 Series with spindle distances of between 600 mm and 1,200 mm were developed as a response to current demands from customers in the automotive industry.

The new CHIRON Series are designed for machining large-volume and complex components such as engine subframes.