Words

and text: Helmut Damm, Workshop + Operation

There is a plethora of technology in the

›Hinterland‹, as the region between Wetzlar and Kassel (in central Germany) is

known. Hundreds of small and medium enterprises are located in the area,

forming a sort of metalworking cluster. Right in the heart of this activity, in

Steffenberg, is Aleit GmbH, developing, constructing and manufacturing

outstanding fixed and rotating precision tools for milling and turning. If you

haven't heard of them, that's probably because Aleit is a behind-the-scenes

company. Their customers include a growing number of leading (and very

well-known) international tool manufacturers and traders, rather than end

customers. The 40-person company has all the expertise in construction and

manufacturing to produce smart, almost-revolutionary tool concepts, but it

doesn't have the capacity for a global sales force targeting end customers.

This makes Aleit a kind of

»Hidden Hidden Champion« in the Hinterland.

Ideas

alone are not enough – it's all in the execution

The

business, which began operation in 1961, has always focused on the

extraordinary and the ambitious. Holger Aleit, son of company founder Gerhard

Aleit and father of today's CEO Björn Aleit says, »Right from the start, we

weren't looking to manufacture standard products; we were looking to work in

the most-demanding field possible in terms of technicality. Our customers still

recognize this today, because we not only develop creative tool solutions, we

offer a comprehensive, fully documented process, from the moment we receive an

order right up to the delivery of an operational tool – including details such

as customer-specific labeling and packaging. That's another of our USPs. It's

not enough to simply have a fantastic idea for a better tool. You need the

expertise to really technically manufacture this idea and execute it in an

economical way. Innovations drive our business, so we cooperate closely with

the Fraunhofer Institute and other similar institutes. This means we always

have our finger on the pulse. In terms of manufacturing, for milling our

variants we work with batch sizes between 1 and 200 and we currently rely on

complete-machining with automated machining centers and milling-turning

machines from the CHIRON Group.«

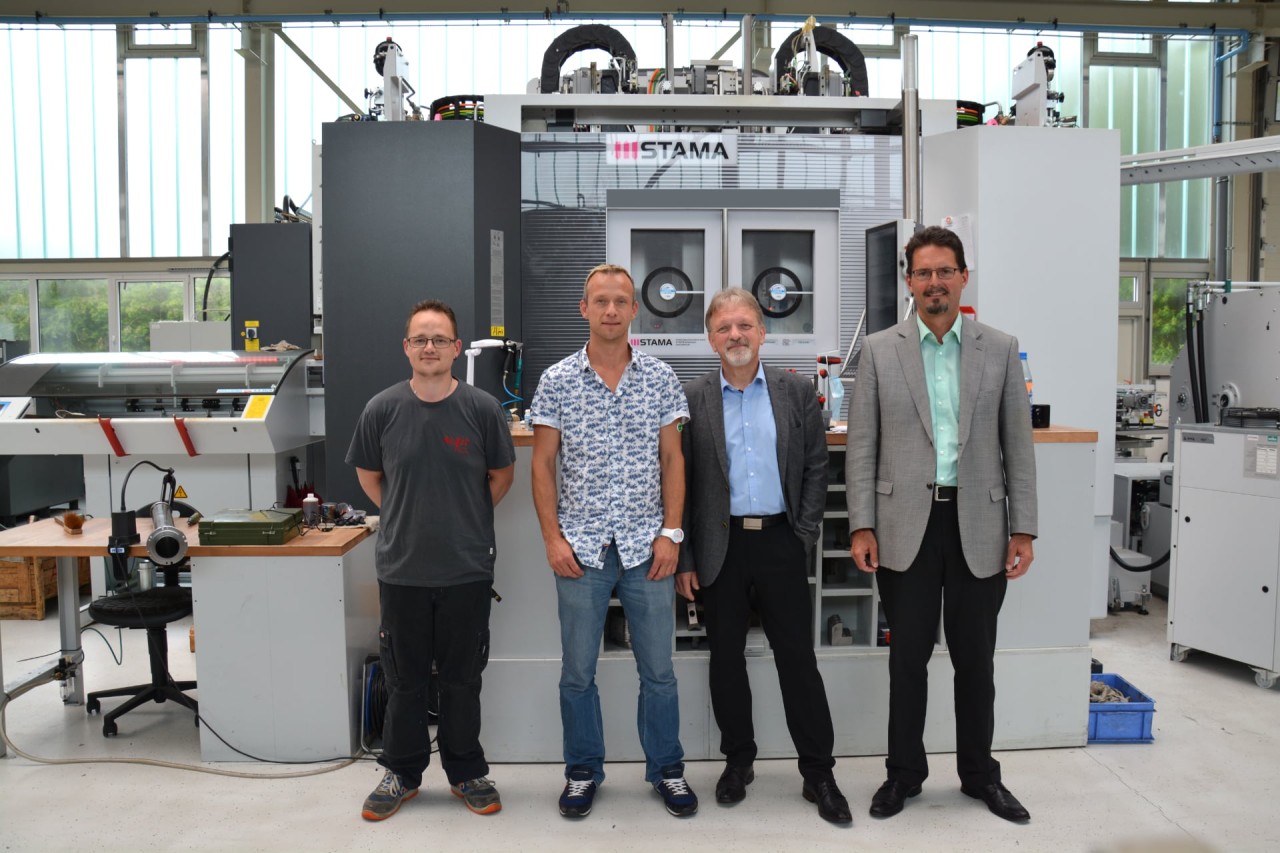

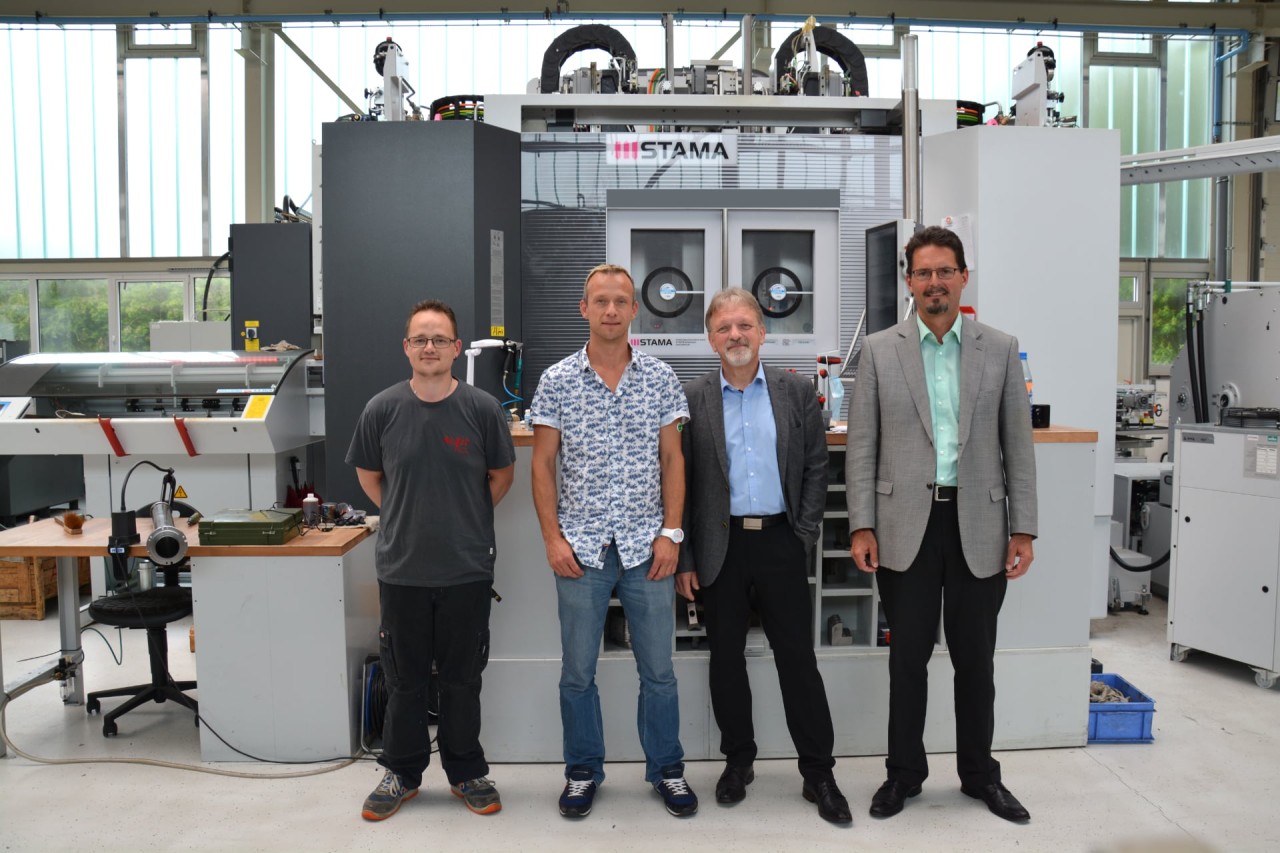

Automated milling-turning complete machining par excellence: Daniel Scheiter, Björn Aleit, Roland Ranisch and Gerhard Schweicker (from left) are pleased with the successful project.

CEO Björn Aleit trained as a milling/cutting

machine operator on milling technology and then was educated in Mechanical

Engineering. He worked in various roles in his family company and took over the

Executive Board at the end of 2017. He knows the company history inside out,

and they have been focusing on precision tools since 1985. Three ›House

specials‹ define the business today and their investment decisions.

Base

frames for milling tools with inserts

Björn

Aleit: »We started by specifically designing and manufacturing the optimum tool

bodies, first and foremost the insert seats, around indexable inserts that

customers provided us with. The requirements for these steadily increased.

Tools, for example, for optical industries with axial running and concentricity

of ≤ 5 µm are de rigueur.«

Modular

tool interfaces

As time went on, the Aleit team began to

wonder why they only focused on the cutting side of the tool and didn't also

consider the back-end, taking on and innovating for the interface to the

spindle, along with the highly complex interior. Today, in Steffenberg, the

team works on all the known interfaces in the market: SK, HSK, PSC (Capto), TS

(KM), ABS, VDI, etc.

CHIRON

FZ 16 S five axis machining center: The quick-to-retool, flexible robot

automation with inventory drawers (right) ensures high levels of productivity.

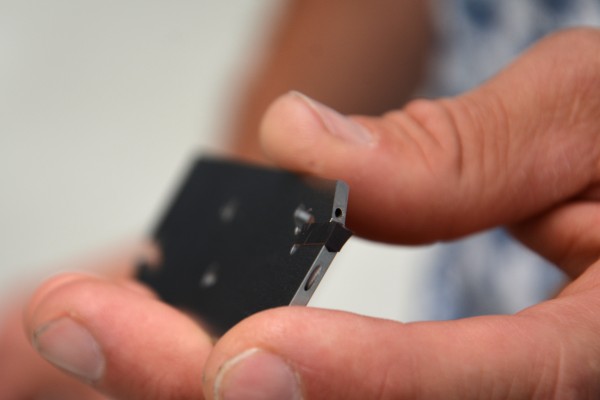

With

the removable blades with interior cooling from above and below (left) and the

clamping-turning holder with coolant-lubricant supply via the shaft to the

blade (right), problem-solver Aleit had landed two hole-in-ones.

Endurance runner: Both STAMA milling-turning centers perform reliably and productively.

Parting

and grooving tools with internal coolant supply and holder

For a long time, Aleit manufactured square

shaft holders for turning in the form of clamping-turning holders and

blade-mounts with various interfaces. It was always a fly in the ointment for the

experts, that the interference contours impeded the feed of the coolant to the

key area. Björn Aleit says, »The problem can't be solved with the standard

cooling in the VDI tool holder. But the coolant is on the holder to use. So, we

developed a sophisticated drill system, which enables the coolant-lubricant to

be guided through the blade from above and below with up to 80 bar pressure

until it reaches the open side of the blade, even for modular systems. The

effects on service life and chip breaking are significant.« Aleit submitted

this idea for a patent, changing the international market as the idea was

adopted by many big tool suppliers as their standard approach.

Complete

machining and automation

In 2007, the firm first made contact with STAMA,

which was already a 100% subsidiary of the CHIRON Group SE. Their research for

efficient and precise complete machining led them to STAMA and they purchased a

milling-turning center MT 726 2C with twin traveling columns. Gerhard

Schweicker, Area Sales Manager for the CHIRON Group explains »The MT 726 2C had

the USP back then, that there were two, five-axis travel column units on one

base frame with integrated turning functionality based on a turning spindle.

The new generation is on a mineral cast base frame with a mobile gantry design.

This allows both short bars and chuck parts to be loaded from above, and then

clamped, transferred and machined flexibly by the spindle. The transfer from

OP10 to OP20 is always highly precise. For turning spindle there is one full

milling spindle and up to 64 tools ready to use, enabling a totally new kind of

heavy-duty machining in comparison to the classic counter-spindle turning

machine with a maximum of 12 tools on the revolver. It doesn't get more

flexible than that.«

Thereafter, the firm also purchased a MT 734

from STAMA. Regarding long-term, largely trouble-free shift operation of the

machines, Björn Aleit talks about his »reliable marathon runners which are

slowly getting older, but have been a fantastic investment.«

Investment

in lifetime flexibility

The next time Aleit needed to invest was in

connection with the complete machining of PSC tools with their various shaft

interfaces. The original manufacturers had previously failed to manufacture the

complex internal contours including eccentric geometry from one cast. For this

task, Aleit selected an F Z16 S five axis which is sold in a package with an

individually tailored robot-automation cell. The extremely stable machine

concept with a swivel bridge mounted on both sides, was impressive from the

start. To this day, the intelligent and, above all, highly flexible and

quick-to-change automation unit makes the big difference to productivity.

Fully automated six-sided

complete machining – the supply and removal belts of the STAMA milling-turning

center transport the heavy parts weighing up to 25 kg to the integrated

workpiece gripper and back again afterwards. On the right is the connected

auxiliary tool magazine with space for 240 tools.

Ten times more accurate

than the manufacturing tolerances – the comprehensive documentation of added

value at Aleit also includes the climate-controlled 3D coordinate measuring

system from Leitz.

Milling-turning

complete machining

Aleit chose the current series of milling-turning

centers with mobile gantry design from STAMA, with the highest level of

configuration. Roland Ranisch, Sales partner at the CHIRON Group says, »In the

end, it was about the universal combination of round profiles, right-angled

profiles and chuck parts which need completely automated machining using millturn.

The two-sided clamping takes place with automated, correctly positioned

internal transfer and five-axis, interpolated processes, so that the components

leave the machine partially finished. Many products then go through the

hardening process, which is followed by a complex grinding process on an

ultra-modern CNC cylindrical grinding machine in a climate-controlled room. The

six-sided machining based on multitasking ensures that machining can take place

on the front and back without a loss in quality.«

It's possible to work with bars up to a

diameter of 102 mm, while chuck parts can have a diameter up to 300 mm. The

supply and discharge belts can move individual parts weighing up to 25 kg to

and from the workpiece gripper, which is located between the two working

chambers and manages the transfer from the main spindle to the counter spindle

for chuck parts. The machine has an autonomous tool inventory of 64 tools per

working chamber and an additional, up-to-240 tools in the auxiliary magazine

which is connected via shuttle.

In response the heat transfer or the mutual

influence of the machine chambers while working, regarding vibrations – machine

operator and foreman Daniel Scheiter has a clear statement, »It promises a lot,

but in this case, it lives up to our expectations. I never experience either

problem in my daily work.«

Customer-focused

even in the future

Aleit is, of course, ISO 9001 certified and

is therefore very well-positioned today. It now has its own product range that

fills an entire catalog. It is also noteworthy, that the firm completely tests

all finished parts including documentation on a Leitz climate-controlled and

decoupled 3D coordinate-measuring device pmm 654, with a measurement

uncertainty of only 0.6 µm, the option for burnishing, the various types of

beam (with corundum, glass balls or stainless steel balls), cylindrical

grinding and laser marking.

But Aleit always has its eye on the future,

because the challenges are only getting more demanding. Digitalization is a hot

topic. As well as DNC-operation, after an ERP-update, Aleit will look to fully

utilize the possibilities of the digital systems in the CHIRON Group SmartLine

portfolio. They are surely on the right track with the idea of

sensor-protected, intelligent tools for a digital fingerprint across the entire

process. With this in mind, a continuing, trusting collaboration between Aleit

and the CHIRON Group is guaranteed.

For more information: www.aleit.de