Mr. Geiselhart, the first topic we would like to address is the recruiting campaign for CHIRON Group Service that was launched in February. Why do we need more staff? Are there new requirements? What do customers expect today and in the future?

Good staff and good products – that is what sets us apart worldwide and across all areas of expertise. The more qualified employees we have in CHIRON Group Service, the stronger we are for our customers, whether remote or on-site. In this respect, of course, our great team should and will continue to grow. Our customers rely on us after purchasing a machining center or an automated manufacturing solution from the CHIRON Group. We have to be there when they need us. Production and cost pressure is increasing year on year – especially in Germany, but also in other countries. This also increases the demands on service, and speed is essential.

However, our recruiting campaign is not only aimed at strengthening our global service, but also has a wider impact: A job here can be the start of a development journey to other roles in the CHIRON Group. If you want to know more: Watch our videos »All eyes on Service«, it's worth it!

Professional, customer-centered service: In your first interview with speedfactor 2019, you set the goal and outlined how important the qualifications of your employees are for this. Can you tell us more about the training program? What sets the CHIRON Group apart from the competition?

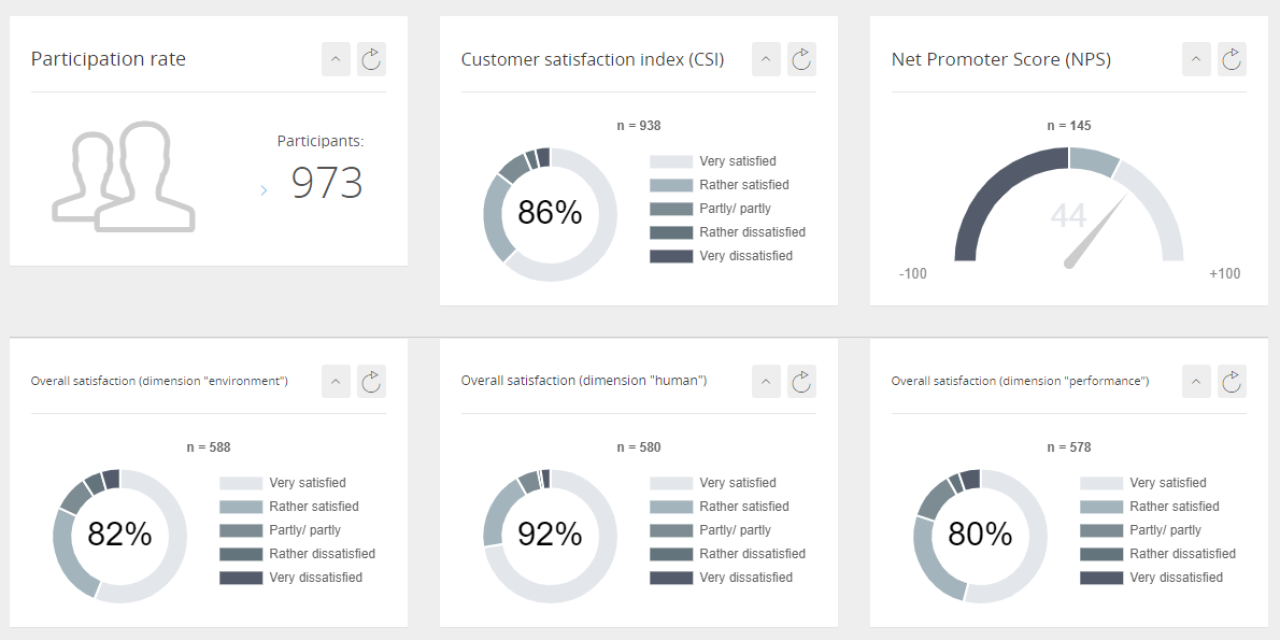

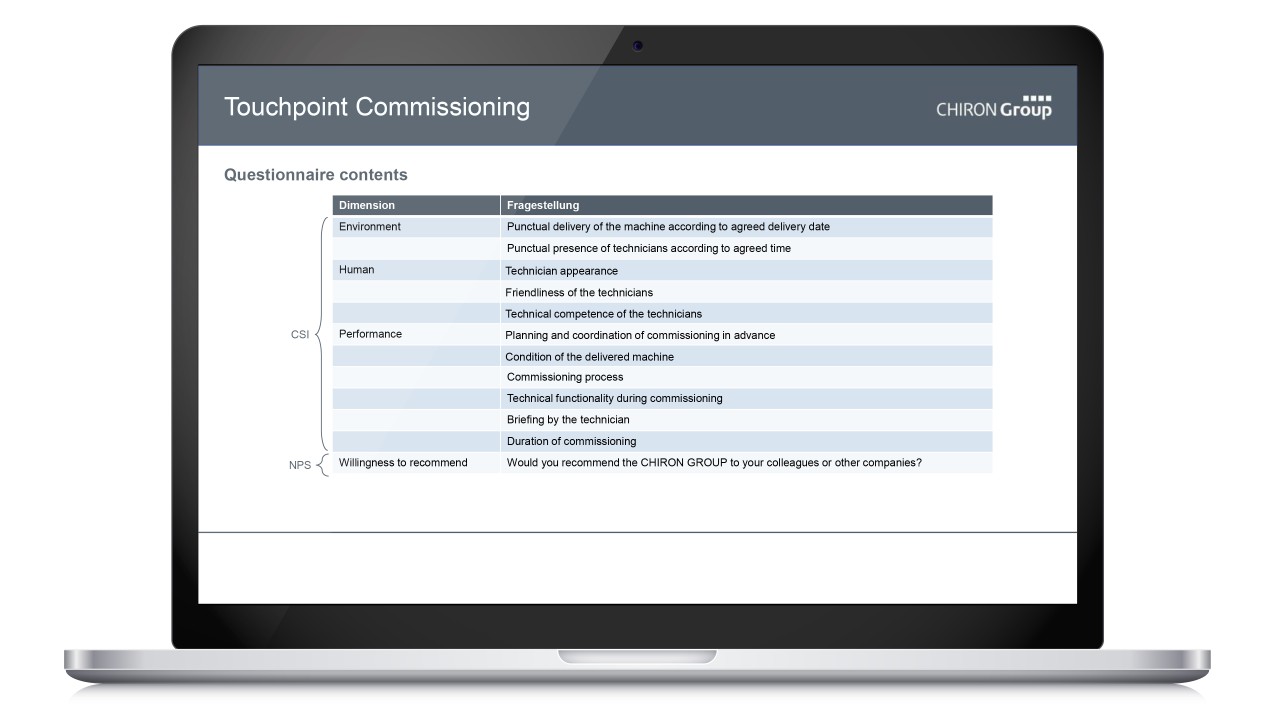

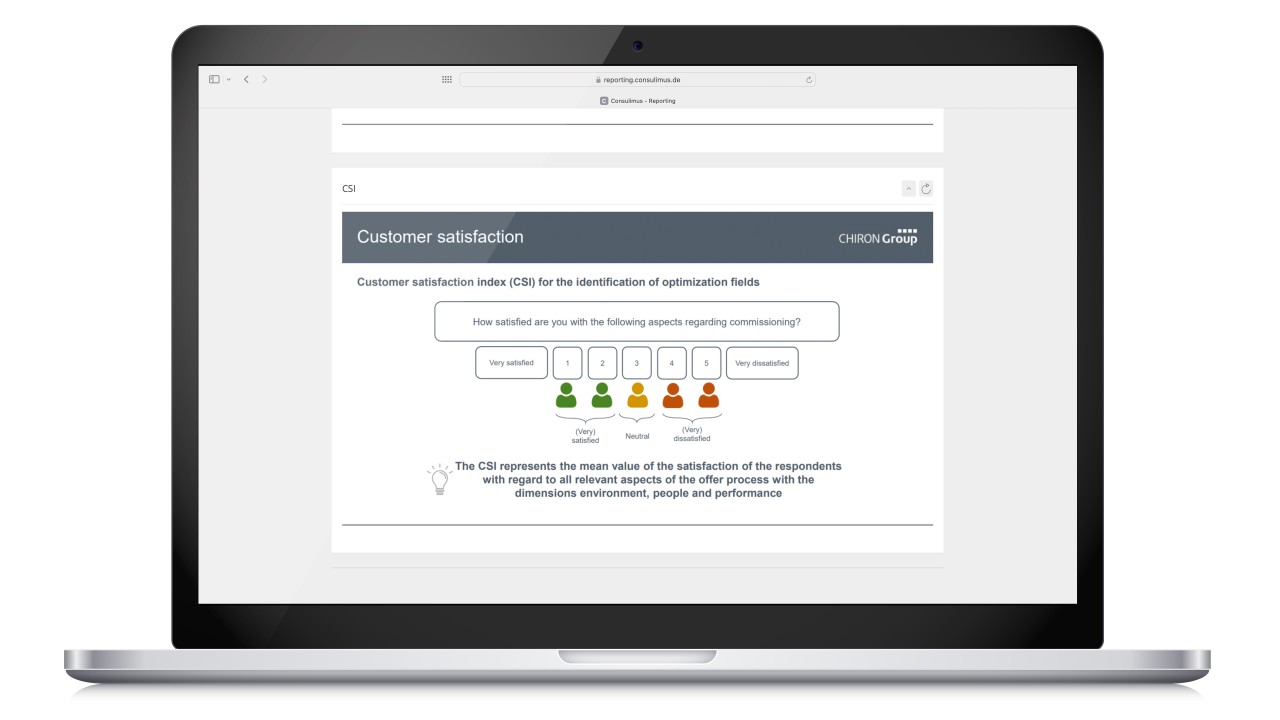

Regardless of the service: Training and further education are very important to us. In total, over 100 young people are undergoing training at various locations. This shows that we are an attractive employer and, of course, I am delighted when the path leads to the service department after graduation. We invest between six and twelve months in training before the first assignment. Teaching technical and product knowledge is just as much a part of the program as »social skills«. Service employees interact with our customers on a daily basis. Personality plays a part in this. They represent the CHIRON Group and that also needs to be learned. Active communication, an engaging manner, recognizing urgency, taking the customer's perspective – we attach great importance to this and also want to make a positive difference beyond the service. We professionally measure how well we succeed in doing this in a continuous survey; after each customer engagement and at other touchpoints.

What exactly is taught during this extensive induction phase? Are there differences depending on the job profile?

We draw up an individual induction and training plan for each new employee. This includes phases in which employees get to know our production centers in the assembly product areas. There are also training blocks in our Academy to acquire skills in fault analysis, repairs and maintenance. Here we differentiate between qualifications for pure mechanics and mechatronics engineers. This is followed by accompanying assignments over several months. Every new service technician has a mentor who coaches them during this time and determines the right time for their first independent assignment.

That's just the internal training. How does CHIRON Group Service ensure that the customer's employees, for example in service and maintenance, are optimally prepared for their tasks?

Qualification is essential for the long-term productive operation of a manufacturing solution. That is why we offer a comprehensive, globally rolled-out program of training, education and qualification measures and constantly adapt the content to current requirements. We teach the basics of service and maintenance, for example, in training courses lasting several days in Tuttlingen, Germany, at the Taicang Innovation Factory and at the CHIRON Group in America.

At the last meeting, we also discussed the new »Service Hub« in the Czech Republic. What does this term mean and what goals are you pursuing with it?

Well, hub can mean turntable, which is exactly how it should be understood. From our subsidiary near Brno, we will provide even faster and better service support to customers from Germany to Austria and the countries of Eastern Europe. In addition, we can schedule the new service staff for longer assignments worldwide and will also become stronger overall. The employees are currently undergoing training in accordance with our global standards. The feedback I received from service manager Marek Stejskal in the review is that the team is developing really well!

»Proactive action« is the common thread that has defined the service strategy for years. This also involves new products that ensure high machine availability and complement traditional on-site services. What service mixes do you offer your customers today and how are new products developed?

We offer, to put it bluntly, well mixed and seasoned :) Overall, we have developed a clear portfolio that is constantly evolving. Since 2019, it has been geared towards the machine lifecycle and the needs of a production and maintenance manager. How do we proceed and implement this? The most important thing is: Listening to customers and understanding »where the shoe pinches«. We then conduct interviews with internal stakeholders, analyze data, develop ideas, formulate added value for our customers and see whether this can be turned into a global business model. If the answer is yes, we derive a new service product, price it, introduce it into the organization, develop sales documents, offer it on the market and request customer feedback in order to optimize it where necessary. Just like you do in product management. Our goal is always to ensure that our service products offer good solutions and help to make the lifetime of a CHIRON Group machining center as profitable as possible for the customer. This is precisely what LifetimeSolutions stands for.

Another topic in the review was the expansion of services, for example with the repair service for axes and spindles, maintenance packages and spare parts packages for the Micro5. Can you say more about this?

Of course! For all Series – from the small Micro5 to the MT 715 – we offer corresponding maintenance contracts in various forms, which can significantly reduce unplanned downtimes. In addition to new and reconditioned spindles, our customers have also been receiving cost-effective repair packages for plug-in and motor spindles directly and quickly from our service warehouse for over a year now. And this applies to spindles from the CHIRON Group as well as to almost all spindles on the market.

In May, we presented PerformanceFinance at the OPEN HOUSE in Tuttlingen, Germany. In addition to financing a machine, this product also includes data-based condition monitoring and a full-service carefree package. Which means, we give our customers maximum technical and financial security for their production and take care of everything that is necessary.

Also, for just over a year, the CHIRON Group has also been a byword for innovative spindle drive technology and has also added the repair, refurbishment and optimization of motor spindles to its service portfolio. How is this offer being received?

Really well. By insourcing the key component of motor spindles, we have completed our core competencies. We already build and repair several hundred spindles a year in our spindle competence center, where the teams at the headquarters in Tuttlingen, Germany and at CHIRON Croatia work closely together. We will continue to expand this area. Firstly, this is an attractive business area and, secondly, we are increasing our service level. With this in mind, we have recently built up additional capacity in Germany, are prepared for further growth and can carry out spindle repairs even faster.

Another innovative offering is the myCHIRON customer portal with an e-shop for spare parts, which was launched last fall at EMO Hanover 2023. How is this being received?

Well! Many customers from the D.A.CH. region are already using myCHIRON. They have access to all relevant information on spare parts at any time via the e-shop and can order them around the clock – until the end of December at a preferential price and always with priority one delivery. Every day we integrate more parts into the e-shop and we still have big plans for myCHIRON. More to come…

SmartServices digital services are an integral part of the offering. One part is EfficiencyServices for optimized reactive maintenance with shorter downtimes, for example through guaranteed response windows and remote access to machine data. Can you explain the added value in more detail?

The added value is enormous! With access via RemoteLine, our experts can identify faults and, in many cases, rectify them directly without the need for an on-site visit and the associated costs. In this way, we not only ensure that the machines can return to production as quickly as possible, but also make our contribution to the ambitious sustainability goals of the CHIRON Group and reduce the CO2 footprint. The added value goes even further: We can see very precisely and specifically how the machining centers are running, see the downtimes and the reasons for them and can thus provide the best possible and proactive support and advice. From the future avoidance of failures to self-initiated troubleshooting and optimization measures. The only requirement: The machines have to be connected to the mains every now and then.

We talked about various new offers. How does the service journey continue? What can customers expect and how can CHIRON Group Service tailor its offerings even more precisely to their requirements?

The focus remains on reliably running machining centers and globally uniformly well-trained service personnel who carry out preventive maintenance competently. Our aim is to serve needs in an even more targeted manner and to provide more customers with the best possible support, for example with customized full service. In future, we will inform customers who order their spare parts via myCHIRON about new functionalities by newsletter and always offer attractive special offers. It is therefore all the more worthwhile to order via the customer portal. As I said at the beginning, we exchange information worldwide at regular intervals. In addition to successes such as the faster provision of spare parts via the new service warehouse, we also address critical points: Where do we receive less positive feedback and need to sharpen up our performance?

I would therefore like to take this opportunity to invite you once again: Join us in the exchange! Tell us what could be improved, which services we should expand and what you think is missing from the portfolio. In short, give us your input for our next meetings so that we can fulfill our promise PERFORMANCE MEETS PRECISION in our service for you even better.

We look forward to receiving your contributions at: [email protected]