The original

plan of the CHIRON Group service team was for one application technician and

two service technicians to fly out to the Vietnamese city of Đà Nẵng at the

beginning of July, to check into a hotel or apartment for eight weeks and stay

within a few minutes' travel of Universal Alloy Corporation Vietnam Co., Ltd

situated at the High-tech Park just outside of the city. They would then work

together with the customer step by step to commission the new machines – four

MILL 4500 and two MILL 8000 machining centers.

A good plan

and, in fact, the only possible approach.

Maybe the

three employees from the CHIRON Group service team could already see themselves

at the famous Bac my An beach after their day's work, dipping their feet in the

sea and taking a quick selfie for their friends and family back home? And maybe

even going on a Sunday excursion to the ancient imperial city of Huế?

But

COVID-19 thwarted all these plans, as travel to Vietnam was not permitted for

an indefinite period of time. A further obstacle to commissioning the machining

centers on time was the fact that HTC, now the service partner for Vietnam, had

not yet been included into the CHIRON Group network since the contract had not

yet been signed. While

the service managers at HTC had

already successfully commissioned a number of machines, none of them had been

CHIRON models.

Nevertheless,

the machines delivered on 1st July 2020 were to start manufacturing workpieces

in large quantities for a renowned aircraft manufacturer as soon as possible.

What was to

be done? Delaying the commissioning of the machines was not an option. Even if

no one wanted to admit it to begin with, there was only one solution. HTC had

to "dive in at the deep end" and

commission the machining centers in Đà Nẵng with, at least initially, constant

remote support from Samuel Baur of the CHIRON Training team. Baur had no idea

how this would work, since all new service partners usually have to undergo an

extended period of training before their first assignment for CHIRON. The MILL

experts were equally perplexed. But Jörg Schmidt, CAD/CAM manager at UACV and

project manager gave the idea the green light. And so the cooperation between

Germany and Vietnam began on 1st July 2020, starting with weekly web

conferences with the participation of multiple CHIRON experts from the sales,

service, application and training departments. For HTC, sales manager Kevin

Hinh took on the role of project manager.

9 a.m. in

Asia/Ho Chi Minh City time. 4 a.m. CET (Central European Time).

For

Samuel Baur, who was working from home at the time due to coronavirus

restrictions, there was at least one silver lining to such an early start – he

did not need to travel to the CHIRON premises during the night, it was just a

short walk over to the living room where he would open up his laptop, a cup of

coffee in hand, wearing his headset. The only thing left was to say "Chào buổi sáng" ("good morning" in Vietnamese) to

the six HTC service personnel, who were already in the large hall at UACV,

ready for a fast-track lesson in the steps required to correctly commission a

CHIRON machining center. The

team was assisted by future operators at UACV, who could also learn a few

things about the new machining centers in the process.

So that no

time was wasted, UACV project manager Jörg Schmidt ensured that the company was

optimally prepared. This included making sure that the machines were in the

right place and that preparations were made for anchoring the machining

centers. After a few small teething problems, a stable Internet connection was

established and Samuel Baur could explain, correct and optimize every action by

video conference or phone. To begin with, this was not the easiest of

undertakings since the English language skills of the Vietnamese service

technicians and even the interpreter were limited with respect to clearly

communicating complex specialist topics. However, over the course of the

project, HTC quickly built up its own expertise and staff gained thorough

practice in the English technical terms.

Better every

time.

The HTC

service team led by Kevin Hinh were

quick learners, requiring less and less time and support each time to carry out

the necessary measures to successfully commission each MILL machining center,

as outlined below.

Connecting and commissioning the attachments and additional units (control

panel, hydraulic unit, vacuum pump, air extraction system, cooling unit and

coolant system)

Aligning and leveling the machine

Measuring and evaluating the machine geometry

Adjusting the tool changer

Measuring and adjusting the five-axis kinematics

We did it!

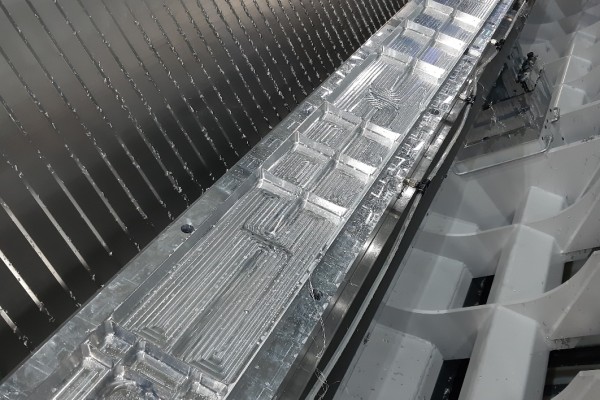

The first MILL 4500 is

installed and the HTC service team is rightly pleased.

The first CHIRON

MILL 4500 machining center was accepted four weeks

after its delivery on 31st July 2020 and the final acceptance date for a

machine was 25th September 2020. In the meantime, all of the machines have now

been commissioned. The MILL 4500 machining centers manufacture nose beams for

the nose section of aircraft, with each system producing six units per month.

Over the same time period, the two MILL 8000 machining centers each produce 60

component families for stringers, which are installed in the fuselage section

of aircraft. During the initial phase of the project, a three-day online

operator training course was held for six employees. The trainer taught the

course from Tuttlingen, Germany, and an HTC employee interpreted.

Each time a

machine was accepted, Samuel Baur needed to give less and less real-time

support, instead coordinating the upcoming work and checking the measurement

results and setting dimensions. He is now working regular hours again and,

needless to say, still acts as a contact for HTC for any questions about

troubleshooting and quality assurance. And, after three months, he has his

living room all to himself again!

From delivery to successful commissioning