The

CHIRON Group first presented the FZ 16 S five axis machining center at AMB in

Stuttgart, Germany in September 2018. An important factor for high productivity

is the fast, automated change of the up to 162 tools in a pick-up process. But

what about the path of the tools in and out of the machine? How can we ensure that the right tool is equipped? How can tools be changed with the

maximum level of security and efficiency?

These

are questions which ZOLLER and the CHIRON Group have investigated and for which

they have found convincing answers as part of a cooperation project true to the

motto »better together«. The approach: Integrating the CHIRON FZ 16 S five axis

machining center into the ZOLLER Smart Factory in Pleidelsheim, Germany to

jointly test innovative procedures for moving tools into the machine and

develop these for series production.

Traditional and critical: Manual data entry

This

is the traditional way of doing things: The

operator prints a label at the setting device, walks to the machine with the

tool and enters the data. However,

statistics indicate that every 20th keystroke is a typing error, with a 4

quickly becoming a 1, or a 5 turning into an 8. It sounds harmless, but during

production this can lead to machining problems and even a machine crash.

»In the Smart Factory, we combine the know-how of machine manufacturers like the CHIRON Group with our expertise. This enables us to expand on issues like connectivity, digitization and automation, develop these further in real circumstances and also experience them live.«

Bernd Schwennig

Head of Sales Automation at ZOLLER

Smart solution, part 1: Secure data transfer to replace paper

chaos

A core competence of ZOLLER is setting and measuring

prepared tool assemblies. The first step of the smart solution is connecting setting and measuring devices to machining centers.

The data can be transferred via RFID tags, which is very secure but also quite

costly. Just as secure but easy and affordable to implement for small companies

is the new data transfer via DataMatrix code.

The

process is incredibly simple: The code on the tool holder is read with a hand

scanner at the setting device, the tool is measured and the actual data is

stored in the central tool database. There is another code reader on the

machining center which is used to clearly identify the tool. The machine

control system then obtains the measuring data including all other required

tool information directly from the tool database and inputs these into the

machine – clearly, automatically and free from errors.

Secure

data transfer is just one of the benefits: The »flash« production analysis

software offered by the specialists from Pleidelsheim makes it possible to

check the tool service life in real time based on a traffic light concept. If

the tools reach the warning limit, a message is generated in the tool setting

space, the new tool can be prepared and equipped in good time.

Smart solution, part 2: Communication, protection

and dynamic action via ProtectLine

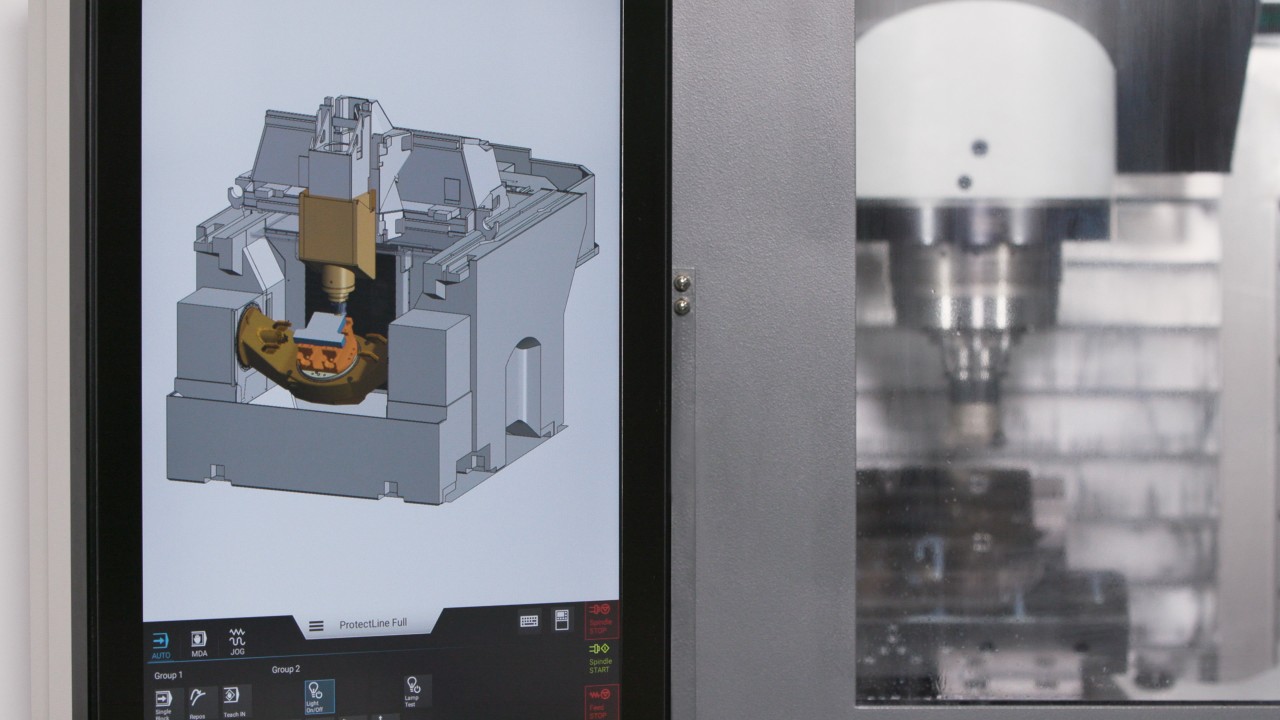

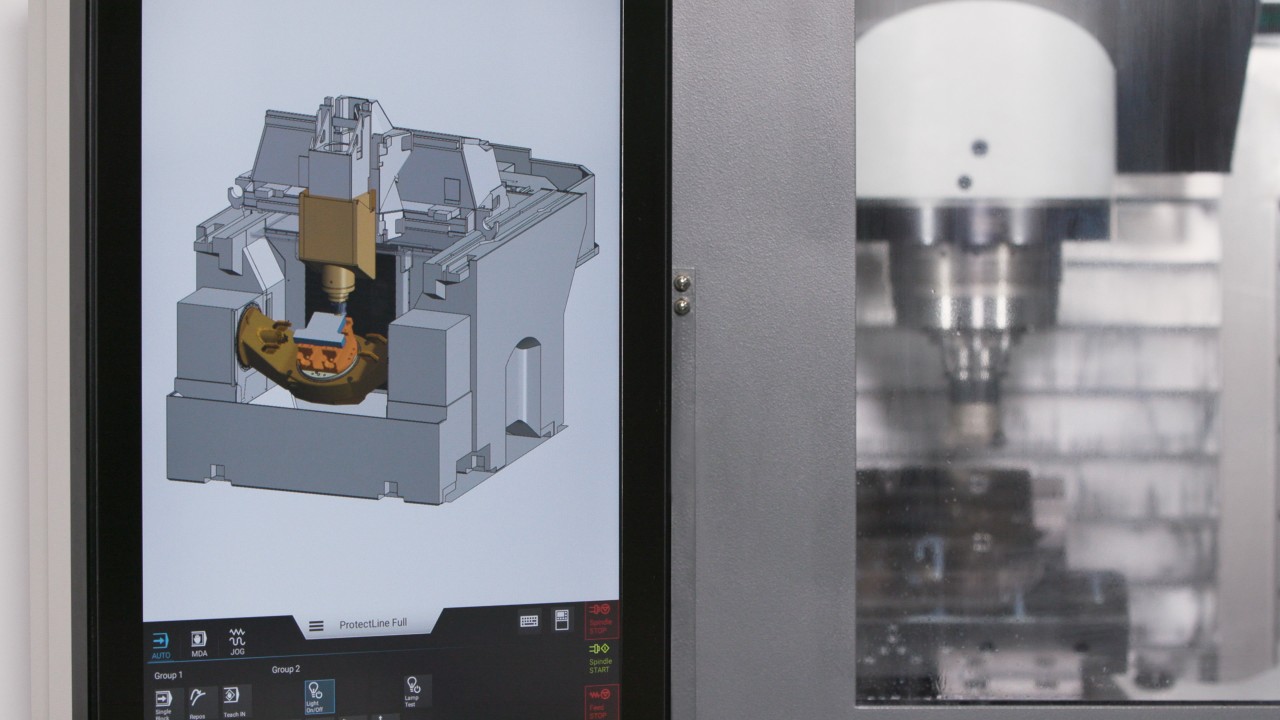

Another result of the

cooperation between ZOLLER and the CHIRON Group is the integration of the full

tool modeling data in ProtectLine. The digital machine

twin is supplemented with the complete tool data – including tool geometry and

tool holder geometry – fully automatically. This creates a highly efficient

process for generating digital twins, which forms the basis in the system for

preventative collision protection for the machine via ProtectLine. »The fully

automatic integration of tools therefore creates significant added value,« explains Pascal Schröder, Development

Coordination Digitalization at the CHIRON Group.

A 3D

scan is generated for the digital tool twin on the Zoller pre-setting device

and automatically provided to the CHIRON Group machining centers in the right

data format.

»The fully automatic integration of tools in ProtectLine creates significant added value. On the one hand, it significantly increases user convenience. On the other hand, a main source of errors – wrong or faulty tool data in the digital model – is excluded.«

Pascal Schröder

Development Coordination Digitalization at the CHIRON Group

Smart solution, part 3: Automated tool handling with

»cora«

When

working with difficult-to-machine materials, such as Inconel or titanium, the

tools need to be changed in a quick rhythm. Frequently changing order sequences

also require correspondingly frequent set-up processes. This takes up work and

machining time – just a few minutes each, but these add up over time and across all machinery. With »cora«, the cooperative robot assistant from

ZOLLER, in combination with the CHIRON Group machining centers, potential for

rationalization can be exploited and clear gains in efficiency can be

achieved.

Benefits:

Save

time thanks to automated tool handling on the setting device

Optimized production thanks to automated tool logistics

Continuous data transfer for maximum security

Data

and stock transparency

Avoid tool-related spindle downtime

Highly productive even with small tool magazines

Excellent solution, pioneering, super digital …

…

great tool, many application options: This is just a small selection from the

all-positive feedback received for the webinar led by Bernd Schwennig on behalf

of the CHIRON Group Sales department.

Would

you experience the solution for yourself? Make a personal appointment for an

online presentation or stop by for a visit at the Smart Factory in Pleidelsheim. To do so, please contact your responsible sales

employee from the CHIRON Group or contact ZOLLER.

As an alternative, you

can also have a first look at the OPEN HOUSE ONLINE during the innovation talk of ZOLLER on the topic »Increase efficiency, ensure quality - integrated tool management and innovative data transmission in practice«.

»At ZOLLER, we generally look at tools with a systematic approach that includes identification, pre-setting, measurements, inspection, automation, storage systems, software, data transfer and digital twin solutions. All this is perfectly implemented in the cooperation project with the CHIRON Group.«

Bernd Schwennig

Head of Sales Automation at ZOLLER

Expect great measures

That is

the motto of E. Zoller GmbH & Co. KG, which offers innovative setting and

measuring devices, software for measurements, inspection and management of

machining tools and automation solutions.

Founded in 1945 by Alfred

Zoller, the company remains an independent family business to this day and

focuses on solutions for greater profitability in machining.

There are currently around

42,000 setting devices and software solutions deployed worldwide, supported by

service and sales branches in the most important markets and partners in 59

countries. Development and assembly are completely »Made in Germany« and based

at the headquarters in Pleidelsheim near Stuttgart. Here, ZOLLER opened a new

building right in time for its 75th anniversary in 2020, and now operates on an

area of 37,000 m2. The building is equipped with geothermal energy,

solar power, water power and a green roof and therefore designed for

sustainability. It offers ideal conditions for around 400 employees and for

training courses held at the ZOLLER Academy. At the heart lies the innovative

technology and customer center, the Smart Factory.