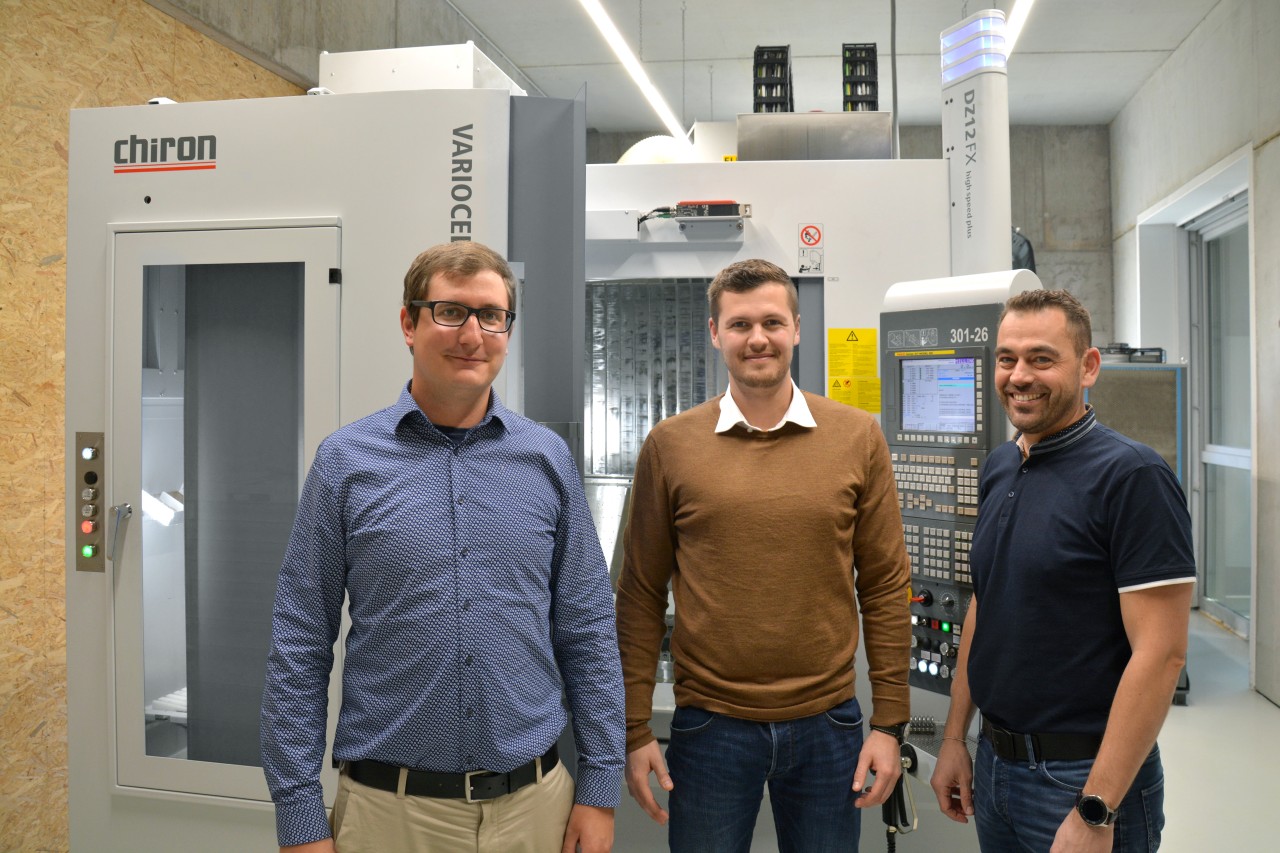

»As an OEM of medical instruments, we are always faced with stricter

requirements for our manufacturing processes. Since the beginning of the year,

the new European Medical Device Regulation (MDR) has required even greater

efforts when it comes to validating and documenting our processes, particularly

for removing production-related residual material from components and

instruments. So that these rising costs are not generally passed on to our

customers, we must not ignore any opportunity to streamline our existing

processes. We believe that purchasing the double-spindle five-axis

machining

center from CHIRON is a key step in this direction since we can operate

this

machine productively around the clock and with minimal staff

supervision, « says Andreas Bacher, Production Manager at Bacher.